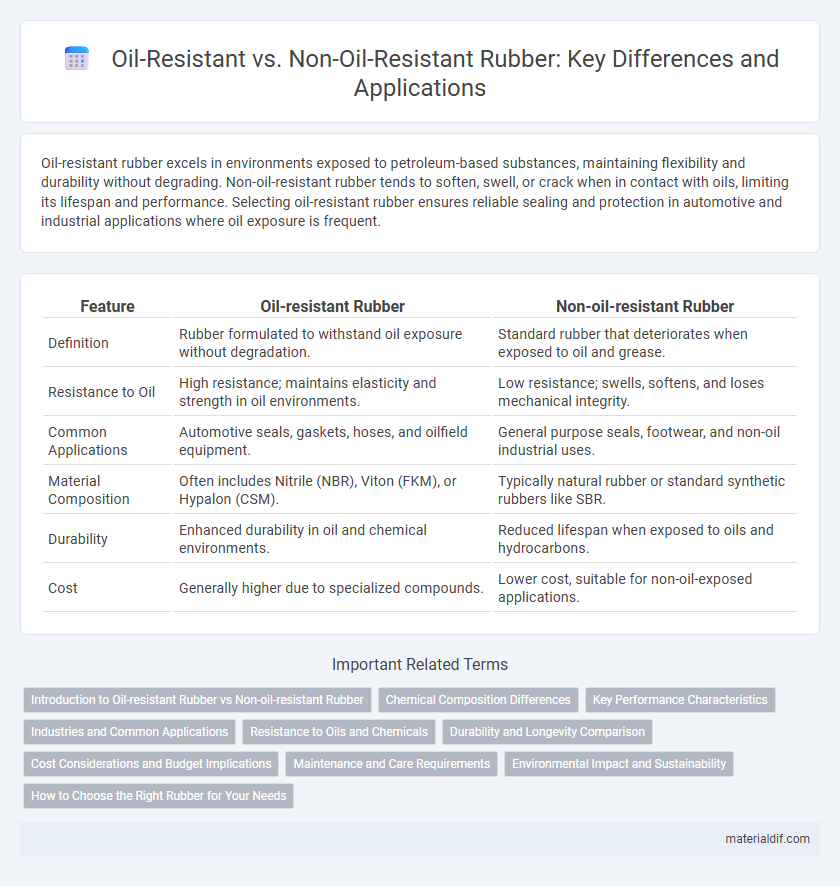

Oil-resistant rubber excels in environments exposed to petroleum-based substances, maintaining flexibility and durability without degrading. Non-oil-resistant rubber tends to soften, swell, or crack when in contact with oils, limiting its lifespan and performance. Selecting oil-resistant rubber ensures reliable sealing and protection in automotive and industrial applications where oil exposure is frequent.

Table of Comparison

| Feature | Oil-resistant Rubber | Non-oil-resistant Rubber |

|---|---|---|

| Definition | Rubber formulated to withstand oil exposure without degradation. | Standard rubber that deteriorates when exposed to oil and grease. |

| Resistance to Oil | High resistance; maintains elasticity and strength in oil environments. | Low resistance; swells, softens, and loses mechanical integrity. |

| Common Applications | Automotive seals, gaskets, hoses, and oilfield equipment. | General purpose seals, footwear, and non-oil industrial uses. |

| Material Composition | Often includes Nitrile (NBR), Viton (FKM), or Hypalon (CSM). | Typically natural rubber or standard synthetic rubbers like SBR. |

| Durability | Enhanced durability in oil and chemical environments. | Reduced lifespan when exposed to oils and hydrocarbons. |

| Cost | Generally higher due to specialized compounds. | Lower cost, suitable for non-oil-exposed applications. |

Introduction to Oil-resistant Rubber vs Non-oil-resistant Rubber

Oil-resistant rubber is specifically formulated to withstand exposure to oils, fuels, and petroleum-based products, making it essential for automotive, industrial, and mechanical applications where contact with such substances is frequent. Non-oil-resistant rubber lacks this specialized resistance and is more suitable for general-purpose uses where exposure to oils is minimal or nonexistent. The molecular structure and additive compounds in oil-resistant rubber provide enhanced durability and prevent swelling, cracking, and degradation caused by oil exposure.

Chemical Composition Differences

Oil-resistant rubber contains specialized polymers such as nitrile rubber (NBR) or fluorocarbon rubber (FKM) that have molecular structures designed to resist degradation by hydrocarbons and oils. Non-oil-resistant rubber typically comprises natural rubber (NR) or styrene-butadiene rubber (SBR), which lack the polar functional groups necessary to repel oil molecules, making them prone to swelling and deterioration upon exposure. The presence of nitrile or fluorinated groups in oil-resistant rubber enhances chemical resistance by reducing polymer affinity for nonpolar oil compounds.

Key Performance Characteristics

Oil-resistant rubber exhibits superior resistance to degradation, swelling, and softening when exposed to petroleum-based oils, making it ideal for automotive seals and gaskets. Non-oil-resistant rubber, while generally more flexible and cost-effective, tends to deteriorate rapidly in oily environments, limiting its use in high-exposure applications. Key performance metrics such as tensile strength, elongation, and chemical resistance significantly favor oil-resistant formulations in industrial and mechanical settings.

Industries and Common Applications

Oil-resistant rubber is extensively used in automotive, aerospace, and industrial machinery sectors where exposure to oils, fuels, and lubricants is frequent, ensuring durability and extended service life of seals, gaskets, and hoses. Non-oil-resistant rubber finds common applications in footwear, toys, and packaging materials, offering flexibility and resilience without the need for chemical resistance. Manufacturing industries prioritize oil-resistant rubber for high-performance parts, while consumer goods industries often rely on non-oil-resistant variants for cost-effective and versatile products.

Resistance to Oils and Chemicals

Oil-resistant rubber exhibits superior resistance to oils, fuels, and various chemicals due to its specialized molecular structure, which prevents swelling and degradation in harsh environments. Non-oil-resistant rubber tends to absorb oils and chemicals, leading to swelling, loss of mechanical properties, and premature failure. The enhanced chemical stability of oil-resistant rubber makes it ideal for automotive, industrial, and chemical applications requiring prolonged exposure to aggressive substances.

Durability and Longevity Comparison

Oil-resistant rubber exhibits superior durability and longevity compared to non-oil-resistant rubber due to its enhanced chemical composition that withstands degradation from petroleum-based products. The molecular structure of oil-resistant rubber resists swelling, cracking, and brittleness when exposed to oils, extending its service life in industrial applications. In contrast, non-oil-resistant rubber degrades rapidly under oil exposure, leading to frequent replacements and increased maintenance costs.

Cost Considerations and Budget Implications

Oil-resistant rubber generally incurs higher costs due to specialized compounds and enhanced durability required to withstand oil exposure. Non-oil-resistant rubber presents a more budget-friendly option for applications without oil contact, minimizing initial expenditure but potentially increasing maintenance costs. Choosing between the two depends on balancing upfront material costs against long-term performance and replacement frequency in specific environmental conditions.

Maintenance and Care Requirements

Oil-resistant rubber requires less frequent maintenance due to its enhanced ability to withstand exposure to oils, preventing surface degradation and maintaining elasticity. Non-oil-resistant rubber demands more diligent care, including regular cleaning and inspection to detect early signs of swelling, cracking, or stiffness caused by oil exposure. Proper storage away from oil sources and immediate cleaning after contact are essential to prolong the lifespan of non-oil-resistant rubber components.

Environmental Impact and Sustainability

Oil-resistant rubber materials often contain specialized additives and synthetic polymers that can complicate recycling processes and increase environmental persistence compared to non-oil-resistant variants, which are generally more biodegradable and easier to recycle. The production of oil-resistant rubber usually requires more energy-intensive chemical treatments, leading to higher carbon emissions and a larger environmental footprint. Selecting non-oil-resistant rubber promotes sustainability by enabling more efficient waste management and reducing toxic residue accumulation in ecosystems.

How to Choose the Right Rubber for Your Needs

Choosing the right rubber depends on the application's exposure to oils, as oil-resistant rubber like nitrile or fluorocarbon offers superior chemical resistance and durability in oily environments. Non-oil-resistant rubbers such as natural rubber or EPDM provide excellent abrasion and weather resistance but deteriorate quickly when in contact with oils or petroleum-based substances. Assessing the specific operational conditions, including temperature, oil type, and mechanical stress, ensures optimal performance and longevity by selecting the appropriate rubber compound.

Oil-resistant Rubber vs Non-oil-resistant Rubber Infographic

materialdif.com

materialdif.com