Hard rubber offers exceptional durability and resistance to abrasion, making it ideal for industrial applications that demand strength and longevity. Soft rubber provides superior flexibility and cushioning, which is essential for products requiring shock absorption and elasticity, such as seals and gaskets. Understanding the distinct properties of hard versus soft rubber enables precise material selection for optimized performance in diverse environments.

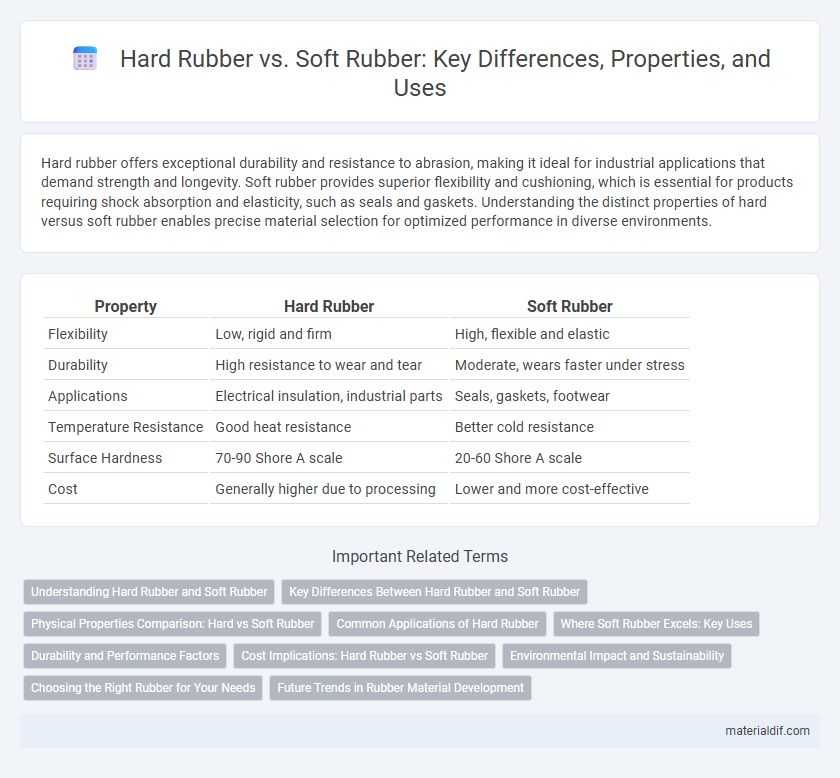

Table of Comparison

| Property | Hard Rubber | Soft Rubber |

|---|---|---|

| Flexibility | Low, rigid and firm | High, flexible and elastic |

| Durability | High resistance to wear and tear | Moderate, wears faster under stress |

| Applications | Electrical insulation, industrial parts | Seals, gaskets, footwear |

| Temperature Resistance | Good heat resistance | Better cold resistance |

| Surface Hardness | 70-90 Shore A scale | 20-60 Shore A scale |

| Cost | Generally higher due to processing | Lower and more cost-effective |

Understanding Hard Rubber and Soft Rubber

Hard rubber, also known as ebonite, is a vulcanized rubber with high sulfur content that results in a rigid, durable material resistant to abrasion and heat, making it ideal for industrial applications like electrical insulators and tool handles. Soft rubber, typically natural or synthetic elastomers with lower sulfur content, offers flexibility, elasticity, and cushioning properties used in products such as seals, gaskets, and flexible tubing. Understanding the differences in sulfur cross-linking and molecular structure clarifies why hard rubber provides hardness and durability, whereas soft rubber delivers pliability and shock absorption.

Key Differences Between Hard Rubber and Soft Rubber

Hard rubber, also known as ebonite, is characterized by its rigidity, high tensile strength, and resistance to heat and chemicals, making it ideal for electrical insulators and tool handles. Soft rubber, typically made from natural or synthetic elastomers, offers greater flexibility, elasticity, and cushioning properties, commonly used in seals, gaskets, and flexible tubing. The key differences hinge on hardness, elasticity, and application suitability, with hard rubber excelling in durability and soft rubber in flexibility.

Physical Properties Comparison: Hard vs Soft Rubber

Hard rubber exhibits higher tensile strength and greater resistance to abrasion compared to soft rubber, making it ideal for durable applications requiring rigidity. Soft rubber offers superior elasticity and flexibility, resulting in enhanced shock absorption and better sealing capabilities under varying temperatures. The density of hard rubber is typically greater, contributing to its stiffness, whereas soft rubber's lower density supports its pliability and cushioning properties.

Common Applications of Hard Rubber

Hard rubber, also known as ebonite, is commonly used in electrical insulators, fountain pen tips, and guitar fingerboards due to its excellent insulating properties and rigidity. Its durability and resistance to heat make it ideal for industrial applications such as valve stems and hard-wearing automotive parts. Hard rubber's ability to maintain shape and resist abrasion ensures its frequent use in laboratory equipment and protective casings.

Where Soft Rubber Excels: Key Uses

Soft rubber excels in applications requiring flexibility and cushioning, such as in seals, gaskets, and vibration dampeners. Its superior elasticity and resistance to wear make it ideal for medical devices, flexible tubing, and protective gloves. Industries like automotive and healthcare rely on soft rubber for components that demand comfort and durability under continuous stress.

Durability and Performance Factors

Hard rubber, known for its high tensile strength and resistance to abrasion, offers superior durability in applications requiring rigidity and long-term wear resistance, such as industrial machinery components and electrical insulators. Soft rubber provides enhanced flexibility, cushioning, and impact absorption, making it ideal for sealing, vibration dampening, and products requiring elasticity, but it generally exhibits lower resistance to tearing and weathering compared to hard rubber. Performance factors depend on the balance between hardness, elasticity, and environmental exposure, with hard rubber excelling in structural durability and soft rubber excelling in dynamic, flexible usage scenarios.

Cost Implications: Hard Rubber vs Soft Rubber

Hard rubber generally incurs higher manufacturing costs due to its complex vulcanization process and longer curing times, resulting in increased energy and labor expenses. Soft rubber offers cost advantages through faster production cycles and lower raw material prices, making it more economical for high-volume applications. Despite initial cost savings, hard rubber's superior durability can lead to lower lifecycle costs in heavy-duty or high-wear environments.

Environmental Impact and Sustainability

Hard rubber, also known as ebonite, is more durable and resistant to chemicals but involves energy-intensive vulcanization processes that contribute to higher carbon emissions. Soft rubber, typically natural or synthetic latex, offers greater biodegradability and lower environmental impact due to its renewable raw material sources and easier recycling potential. Choosing soft rubber supports sustainability efforts by reducing landfill waste and promoting eco-friendly material cycles in the rubber industry.

Choosing the Right Rubber for Your Needs

Hard rubber offers superior durability and resistance to abrasion, making it ideal for applications requiring long-lasting performance under heavy wear. Soft rubber provides greater flexibility and cushioning, suitable for products needing shock absorption and enhanced grip. Selecting the right rubber depends on balancing factors like mechanical stress, environmental exposure, and desired elasticity.

Future Trends in Rubber Material Development

Future trends in rubber material development emphasize enhancing the durability and flexibility of both hard rubber and soft rubber through advanced polymer composites and nanotechnology. Innovations in bio-based and recycled rubber materials aim to improve sustainability while maintaining performance characteristics critical for automotive, industrial, and consumer applications. Research on smart rubber materials with self-healing properties and improved thermal resistance is expected to transform the rubber industry by extending product lifespan and reducing environmental impact.

Hard Rubber vs Soft Rubber Infographic

materialdif.com

materialdif.com