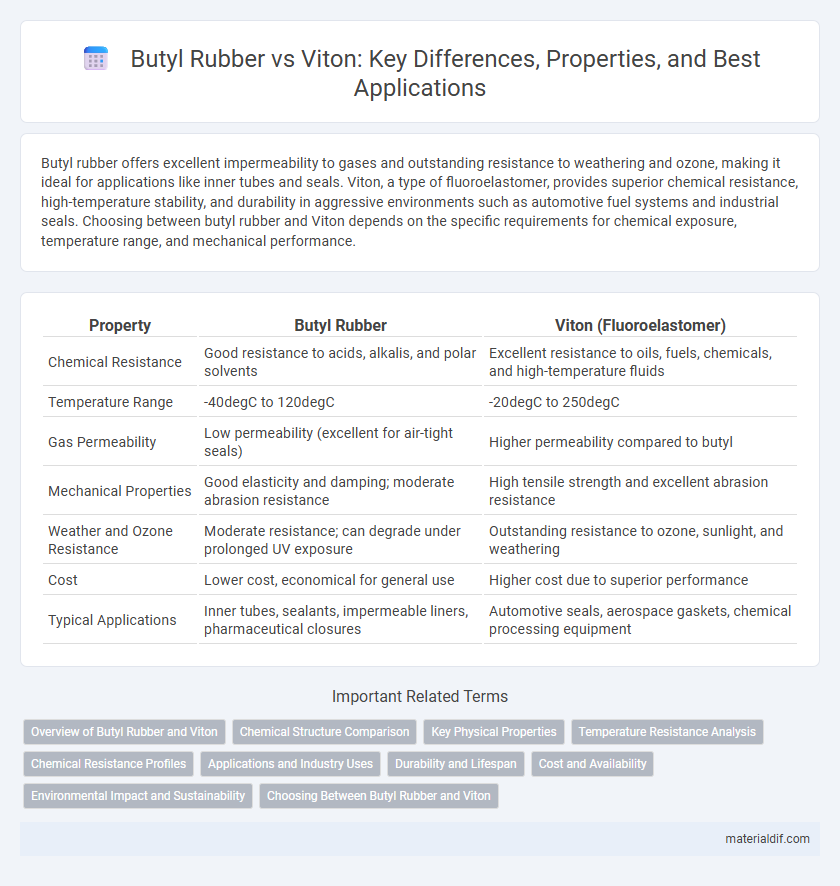

Butyl rubber offers excellent impermeability to gases and outstanding resistance to weathering and ozone, making it ideal for applications like inner tubes and seals. Viton, a type of fluoroelastomer, provides superior chemical resistance, high-temperature stability, and durability in aggressive environments such as automotive fuel systems and industrial seals. Choosing between butyl rubber and Viton depends on the specific requirements for chemical exposure, temperature range, and mechanical performance.

Table of Comparison

| Property | Butyl Rubber | Viton (Fluoroelastomer) |

|---|---|---|

| Chemical Resistance | Good resistance to acids, alkalis, and polar solvents | Excellent resistance to oils, fuels, chemicals, and high-temperature fluids |

| Temperature Range | -40degC to 120degC | -20degC to 250degC |

| Gas Permeability | Low permeability (excellent for air-tight seals) | Higher permeability compared to butyl |

| Mechanical Properties | Good elasticity and damping; moderate abrasion resistance | High tensile strength and excellent abrasion resistance |

| Weather and Ozone Resistance | Moderate resistance; can degrade under prolonged UV exposure | Outstanding resistance to ozone, sunlight, and weathering |

| Cost | Lower cost, economical for general use | Higher cost due to superior performance |

| Typical Applications | Inner tubes, sealants, impermeable liners, pharmaceutical closures | Automotive seals, aerospace gaskets, chemical processing equipment |

Overview of Butyl Rubber and Viton

Butyl rubber is a synthetic elastomer composed primarily of isobutylene with small amounts of isoprene, known for its excellent impermeability to gases and superior resistance to heat, chemicals, and weathering. Viton, a brand of fluorocarbon rubber (FKM), features high-performance fluoroelastomer properties, offering outstanding chemical resistance, thermal stability, and durability in extreme environments. Both materials serve critical roles in sealing, automotive, and industrial applications, with butyl rubber favored for air retention and Viton preferred for aggressive chemical exposure and high-temperature settings.

Chemical Structure Comparison

Butyl rubber consists of a copolymer of isobutylene with a small amount of isoprene, creating a saturated polymer backbone that enhances its impermeability and flexibility. Viton, a brand of fluoroelastomer, features a chemical structure based on vinylidene fluoride and hexafluoropropylene monomers, resulting in high chemical resistance and temperature stability due to the presence of fluorine atoms. The key structural difference lies in butyl rubber's hydrocarbon backbone versus Viton's fluorinated polymer chain, which imparts superior chemical inertness and thermal performance to Viton.

Key Physical Properties

Butyl rubber exhibits excellent impermeability to gases and good flexibility at low temperatures, with a tensile strength around 3-7 MPa and elongation at break of 300-600%. Viton, a type of fluoroelastomer, offers superior chemical resistance and higher thermal stability, maintaining integrity at temperatures up to 200-250degC, with tensile strength typically between 10-20 MPa and elongation at break approximately 200-300%. The choice between butyl rubber and Viton depends on application requirements for chemical exposure, temperature range, and mechanical durability.

Temperature Resistance Analysis

Butyl rubber offers excellent resistance to heat up to approximately 120degC, making it suitable for moderate temperature applications. Viton, a fluorocarbon elastomer, withstands significantly higher temperatures, typically ranging from -26degC to 204degC, with some grades tolerating continuous exposure up to 250degC. The superior thermal stability of Viton makes it ideal for automotive, aerospace, and industrial sealing applications requiring enhanced heat and chemical resistance.

Chemical Resistance Profiles

Butyl rubber exhibits excellent resistance to polar solvents, acids, and alkalis, making it ideal for seals in harsh chemical environments. Viton, a fluorocarbon elastomer, offers superior resistance to hydrocarbons, high temperatures, and aggressive chemicals such as oils and fuels. The chemical resistance profile of Viton outperforms butyl rubber particularly in exposure to aromatic and chlorinated solvents.

Applications and Industry Uses

Butyl rubber excels in applications requiring excellent impermeability and chemical resistance, making it ideal for automotive inner liners, medical devices like pharmaceutical stoppers, and protective clothing. Viton, a fluoroelastomer, is preferred in industries demanding superior heat, fuel, and chemical resistance, such as aerospace seals, automotive fuel system components, and industrial O-rings. Both materials serve critical roles in manufacturing, with butyl rubber dominating in pressure retention and air barriers, while Viton leads in high-performance sealing under extreme conditions.

Durability and Lifespan

Butyl rubber offers exceptional resistance to ozone, weathering, and aging, ensuring durability in sealing applications with a typical lifespan of 10 to 15 years. Viton, a fluoroelastomer, excels in chemical resistance and high-temperature stability, providing durability in harsh environments with a lifespan often exceeding 15 years under extreme conditions. Both materials demonstrate strong durability, but Viton generally outperforms butyl rubber in longevity when exposed to aggressive chemicals and elevated temperatures.

Cost and Availability

Butyl rubber is generally more cost-effective and widely available compared to Viton, making it a preferred choice for applications requiring economical yet durable elastomers. Viton, a fluorocarbon-based rubber, commands a higher price due to its superior chemical and heat resistance, limiting its availability to specialized industrial uses. Procurement decisions often weigh Butyl rubber's affordability and accessibility against Viton's premium performance characteristics.

Environmental Impact and Sustainability

Butyl rubber, derived from isobutylene and small amounts of isoprene, is known for its excellent air impermeability and chemical resistance, making it a sustainable choice due to its longer lifecycle in tire inner liners and other applications. Viton, a fluorocarbon-based synthetic rubber, offers superior resistance to heat, fuels, and chemicals but poses environmental challenges in production and disposal because of its fluorinated polymer structure, which can lead to persistent environmental pollutants. In terms of environmental impact, butyl rubber exhibits a lower ecological footprint due to easier recycling and biodegradability compared to Viton's more complex degradation and higher energy-intensive manufacturing process.

Choosing Between Butyl Rubber and Viton

Choosing between butyl rubber and Viton depends on the application's chemical resistance and temperature requirements. Butyl rubber offers excellent impermeability and flexibility, making it ideal for air-filled products and seals in moderate temperature environments. Viton provides superior resistance to heat, oils, and aggressive chemicals, suited for high-performance automotive and industrial seals exposed to extreme conditions.

Butyl Rubber vs Viton Infographic

materialdif.com

materialdif.com