Isoprene rubber offers excellent elasticity and resilience, closely mimicking natural rubber, making it ideal for tires and footwear applications. Polybutadiene rubber excels in wear resistance and low heat buildup, enhancing durability in high-performance tires and industrial products. Both rubbers provide unique advantages, with isoprene favored for flexibility and polybutadiene valued for toughness and abrasion resistance.

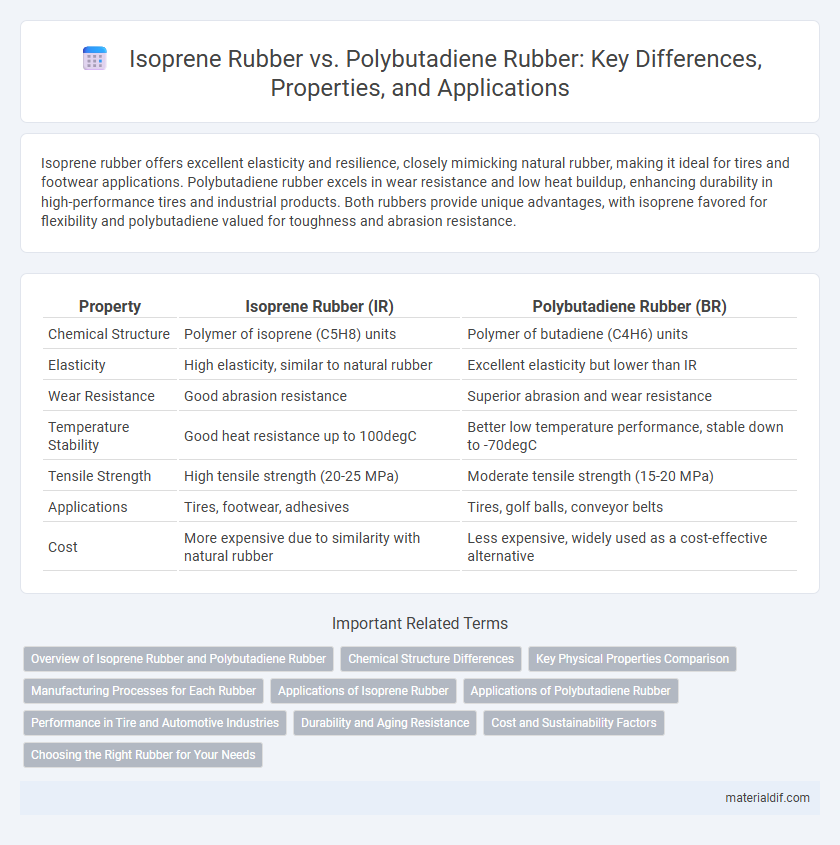

Table of Comparison

| Property | Isoprene Rubber (IR) | Polybutadiene Rubber (BR) |

|---|---|---|

| Chemical Structure | Polymer of isoprene (C5H8) units | Polymer of butadiene (C4H6) units |

| Elasticity | High elasticity, similar to natural rubber | Excellent elasticity but lower than IR |

| Wear Resistance | Good abrasion resistance | Superior abrasion and wear resistance |

| Temperature Stability | Good heat resistance up to 100degC | Better low temperature performance, stable down to -70degC |

| Tensile Strength | High tensile strength (20-25 MPa) | Moderate tensile strength (15-20 MPa) |

| Applications | Tires, footwear, adhesives | Tires, golf balls, conveyor belts |

| Cost | More expensive due to similarity with natural rubber | Less expensive, widely used as a cost-effective alternative |

Overview of Isoprene Rubber and Polybutadiene Rubber

Isoprene rubber, a synthetic polymer mimicking natural rubber, offers excellent elasticity, resilience, and abrasion resistance, making it ideal for automotive tires and footwear. Polybutadiene rubber is characterized by its high wear resistance and low-temperature flexibility, commonly used in tire treads, golf balls, and conveyor belts. Both rubbers contribute significantly to the rubber industry by enhancing performance in diverse industrial applications.

Chemical Structure Differences

Isoprene rubber consists of repeating units derived from isoprene monomers featuring a conjugated diene structure with a methyl group attached to the second carbon, influencing its cis-1,4 configuration. Polybutadiene rubber is composed of polymerized butadiene monomers, predominantly exhibiting cis-1,4 and trans-1,4 configurations without methyl side groups, which impacts its flexibility and resistance properties. These chemical structural differences determine the variations in elasticity, resilience, and industrial applications between isoprene and polybutadiene rubbers.

Key Physical Properties Comparison

Isoprene rubber exhibits excellent tensile strength and elasticity, with a higher resilience and better abrasion resistance compared to polybutadiene rubber, which offers superior low-temperature flexibility and lower glass transition temperature (Tg). Polybutadiene rubber generally demonstrates enhanced wear resistance and higher impact strength, making it suitable for applications requiring toughness under mechanical stress. Both rubbers have distinct molecular structures influencing their hardness, elasticity, and resistance to aging, critical factors in selecting materials for automotive tires, industrial goods, and footwear.

Manufacturing Processes for Each Rubber

Isoprene rubber is synthesized through the polymerization of isoprene monomers using catalysts such as Ziegler-Natta or neodymium-based systems, resulting in high cis-1,4-polyisoprene content that mimics natural rubber properties. Polybutadiene rubber is produced by polymerizing butadiene monomers via anionic or coordination polymerization methods, typically employing catalysts like organolithium compounds or neodymium catalysts to achieve a high cis-1,4-polybutadiene structure for enhanced abrasion resistance. Both manufacturing processes require precise control of temperature, catalyst concentration, and reaction time to tailor molecular weight and microstructure, optimizing the performance characteristics for applications such as tires and industrial rubber goods.

Applications of Isoprene Rubber

Isoprene rubber exhibits superior elastic properties and resistance to abrasion, making it ideal for manufacturing high-performance tires, surgical gloves, and adhesives. Its excellent tensile strength and resilience are favored in medical devices and footwear soles. Isoprene's biocompatibility and stability under mechanical stress expand its application in biomedical and industrial sectors.

Applications of Polybutadiene Rubber

Polybutadiene rubber is widely used in tire manufacturing due to its excellent abrasion resistance and high wear durability, enhancing tire lifespan and performance. It is also a key component in golf balls and various industrial rubber goods, such as conveyor belts and automotive parts, where impact resistance and flexibility are crucial. Its superior low-temperature flexibility makes it ideal for use in sealants and adhesives in cold environments.

Performance in Tire and Automotive Industries

Isoprene rubber exhibits superior abrasion resistance and resilience, making it ideal for tire treads that require high durability and traction. Polybutadiene rubber offers excellent low-temperature flexibility and impact strength, enhancing tire sidewalls and automotive parts prone to mechanical stress. Combining both rubbers in tire compounds optimizes performance by balancing wear resistance, elasticity, and fuel efficiency.

Durability and Aging Resistance

Isoprene rubber offers superior aging resistance due to its high purity and natural origin, which provides excellent resistance to ozone, heat, and weathering. Polybutadiene rubber exhibits enhanced durability and abrasion resistance, making it ideal for high-wear applications such as tires and industrial products. Both rubbers maintain mechanical properties over time, but isoprene rubber excels in long-term environmental stability while polybutadiene rubber delivers outstanding resilience under repetitive stress.

Cost and Sustainability Factors

Isoprene rubber generally carries a higher production cost compared to polybutadiene rubber due to its more complex synthesis and refining processes, impacting overall material expenses. Polybutadiene rubber demonstrates better sustainability as it often requires less energy-intensive production and can be sourced partially from bio-based feedstocks, reducing its carbon footprint. The economic and environmental trade-offs between isoprene and polybutadiene rubber significantly influence their selection in automotive and industrial applications.

Choosing the Right Rubber for Your Needs

Isoprene rubber offers excellent tensile strength, elasticity, and resistance to fatigue, making it ideal for products requiring high durability and flexibility like medical gloves and adhesives. Polybutadiene rubber excels in wear resistance and low rolling resistance, commonly used in tire manufacturing and industrial applications where abrasion and impact resistance are critical. Selecting the right rubber depends on application-specific demands such as mechanical properties, environmental exposure, and cost-efficiency.

Isoprene Rubber vs Polybutadiene Rubber Infographic

materialdif.com

materialdif.com