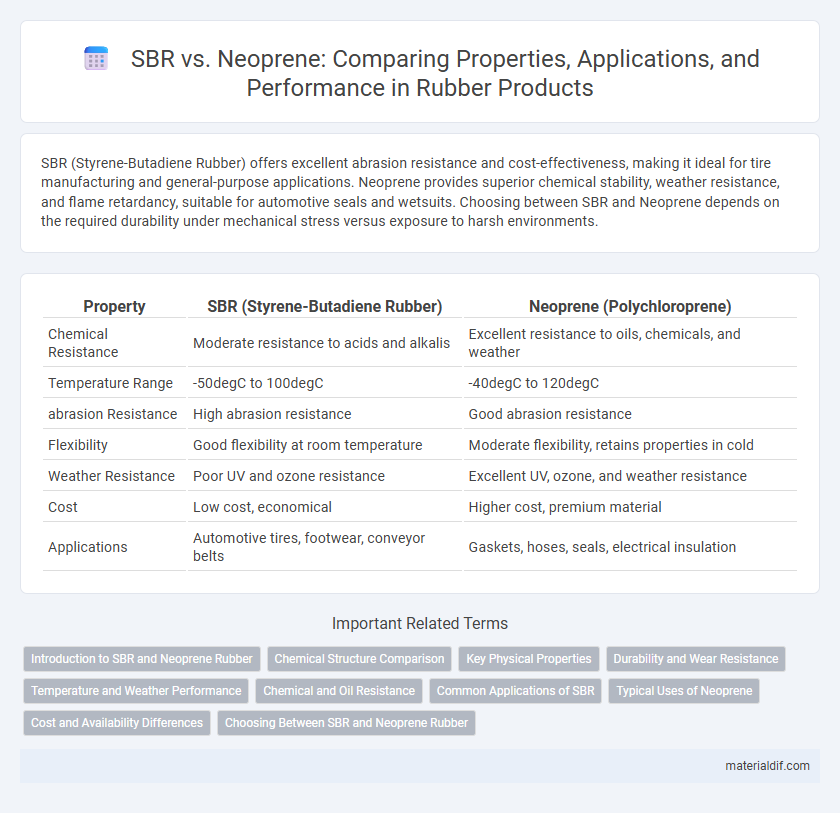

SBR (Styrene-Butadiene Rubber) offers excellent abrasion resistance and cost-effectiveness, making it ideal for tire manufacturing and general-purpose applications. Neoprene provides superior chemical stability, weather resistance, and flame retardancy, suitable for automotive seals and wetsuits. Choosing between SBR and Neoprene depends on the required durability under mechanical stress versus exposure to harsh environments.

Table of Comparison

| Property | SBR (Styrene-Butadiene Rubber) | Neoprene (Polychloroprene) |

|---|---|---|

| Chemical Resistance | Moderate resistance to acids and alkalis | Excellent resistance to oils, chemicals, and weather |

| Temperature Range | -50degC to 100degC | -40degC to 120degC |

| abrasion Resistance | High abrasion resistance | Good abrasion resistance |

| Flexibility | Good flexibility at room temperature | Moderate flexibility, retains properties in cold |

| Weather Resistance | Poor UV and ozone resistance | Excellent UV, ozone, and weather resistance |

| Cost | Low cost, economical | Higher cost, premium material |

| Applications | Automotive tires, footwear, conveyor belts | Gaskets, hoses, seals, electrical insulation |

Introduction to SBR and Neoprene Rubber

SBR (Styrene-Butadiene Rubber) is a synthetic rubber known for its excellent abrasion resistance and aging stability, widely used in tires, footwear, and industrial products. Neoprene, or polychloroprene, offers superior chemical resistance, weathering, and oil resistance, making it ideal for seals, gaskets, and protective coatings. Both SBR and Neoprene serve crucial roles in different industries due to their distinct physical properties and performance characteristics.

Chemical Structure Comparison

SBR (Styrene-Butadiene Rubber) is a copolymer consisting primarily of styrene and butadiene monomers, offering a predominantly hydrocarbon backbone with vinyl and conjugated diene functionalities that contribute to its elasticity and abrasion resistance. Neoprene, chemically known as polychloroprene, contains chlorinated butadiene units resulting in a polymer with chlorine atoms attached to the backbone, which impart superior chemical stability, weather resistance, and flame retardancy compared to SBR. The presence of chlorine in Neoprene's chemical structure enhances polarity and intermolecular forces, differentiating it significantly from the non-polar, less chemically resistant structure of SBR.

Key Physical Properties

SBR (Styrene-Butadiene Rubber) offers excellent abrasion resistance and good aging stability but has limited resistance to oils and chemicals compared to Neoprene (Chloroprene Rubber). Neoprene provides superior chemical, oil, and weather resistance with moderate tensile strength and elasticity, making it ideal for harsh environments. Both rubbers exhibit similar hardness ranges, but Neoprene's enhanced resistance to UV and ozone significantly extends its service life in outdoor applications.

Durability and Wear Resistance

SBR (Styrene-Butadiene Rubber) is valued for its excellent abrasion resistance and good aging stability, making it durable for applications like tires and footwear. Neoprene (Polychloroprene) offers superior chemical resistance and maintains flexibility over a wide temperature range, enhancing wear resistance in harsh environments. Compared to SBR, Neoprene exhibits better resistance to oils, ozone, and weathering, contributing to longer service life in industrial and outdoor applications.

Temperature and Weather Performance

SBR (Styrene-Butadiene Rubber) offers good resistance to abrasion and aging but performs best within moderate temperature ranges, typically up to 80degC (176degF). Neoprene excels in temperature resilience, maintaining flexibility and durability from -40degC to 120degC (-40degF to 248degF), and provides superior weather resistance including UV, ozone, and chemical exposure. These properties make Neoprene more suitable for outdoor and harsh weather applications compared to SBR.

Chemical and Oil Resistance

SBR (Styrene-Butadiene Rubber) exhibits moderate chemical resistance but tends to degrade when exposed to oils and hydrocarbons, limiting its use in oil-rich environments. Neoprene, or polychloroprene, offers superior chemical and oil resistance, maintaining flexibility and durability in harsh conditions involving petroleum-based products. This makes Neoprene the preferred choice for applications requiring enhanced protection against oils, greases, and various chemicals.

Common Applications of SBR

Styrene-Butadiene Rubber (SBR) is widely used in automotive tires, conveyor belts, and footwear due to its excellent abrasion resistance and cost-effectiveness. SBR's strong performance in mechanical applications makes it a preferred material for gaskets, seals, and hoses in industrial equipment. Its versatility in various temperature ranges and good aging stability enhances its suitability for everyday consumer goods and industrial products.

Typical Uses of Neoprene

Neoprene is commonly used in wetsuits, orthopedic braces, automotive gaskets, and industrial hoses due to its excellent resistance to oil, chemicals, and weathering. Its unique ability to maintain flexibility over a wide temperature range makes it ideal for protective clothing and sealants in harsh environments. Unlike SBR, neoprene provides superior durability for applications involving exposure to ozone and UV radiation.

Cost and Availability Differences

SBR (Styrene-Butadiene Rubber) is generally more cost-effective and widely available than Neoprene due to its simpler manufacturing process and extensive production scale. Neoprene rubber commands a higher price because of its superior chemical resistance and specialized applications, which limits its mass availability. The cost difference significantly impacts industrial choices, with SBR favored for budget-sensitive projects and Neoprene selected for environments requiring enhanced durability.

Choosing Between SBR and Neoprene Rubber

Choosing between SBR and Neoprene rubber depends on the application's requirements for durability and chemical resistance; SBR excels in abrasion resistance and cost-effectiveness, making it ideal for automotive tires and footwear soles. Neoprene offers superior resistance to oils, ozone, and weathering, preferred in industrial gaskets, hoses, and protective gear. Assessing exposure conditions and mechanical demands guides optimal selection for performance and longevity.

SBR vs Neoprene Infographic

materialdif.com

materialdif.com