Rubber hardness measures resistance to indentation, directly impacting durability and wear resistance in applications. Elasticity reflects rubber's ability to stretch and return to its original shape, crucial for flexibility and shock absorption. Balancing hardness and elasticity optimizes performance for specific uses, such as tires needing both toughness and flexibility.

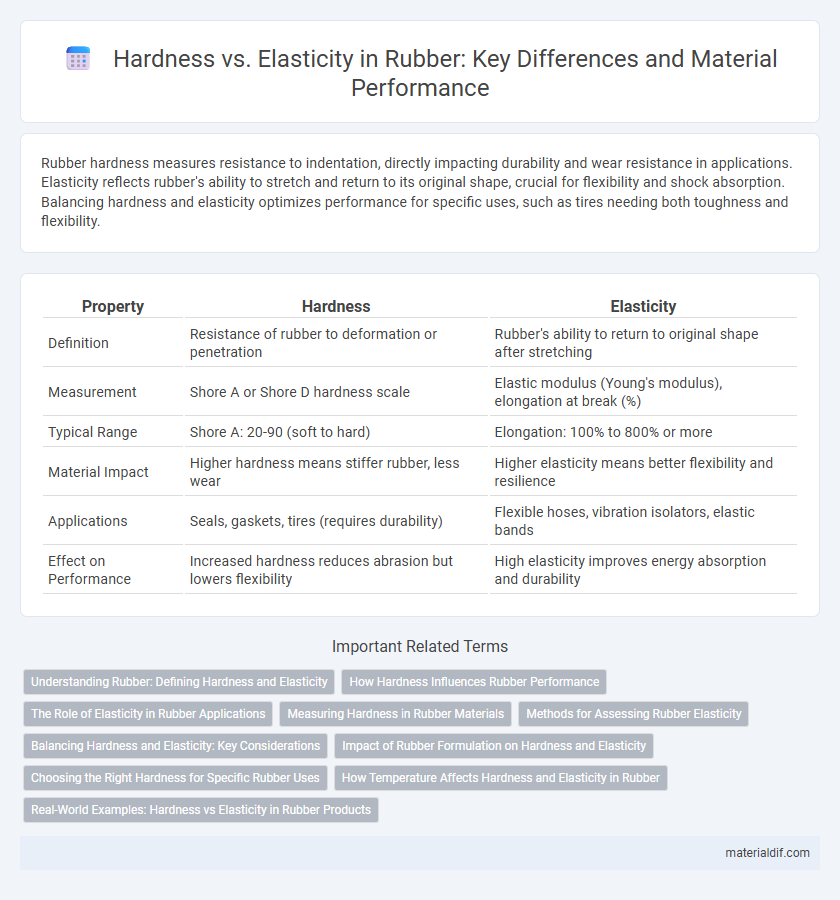

Table of Comparison

| Property | Hardness | Elasticity |

|---|---|---|

| Definition | Resistance of rubber to deformation or penetration | Rubber's ability to return to original shape after stretching |

| Measurement | Shore A or Shore D hardness scale | Elastic modulus (Young's modulus), elongation at break (%) |

| Typical Range | Shore A: 20-90 (soft to hard) | Elongation: 100% to 800% or more |

| Material Impact | Higher hardness means stiffer rubber, less wear | Higher elasticity means better flexibility and resilience |

| Applications | Seals, gaskets, tires (requires durability) | Flexible hoses, vibration isolators, elastic bands |

| Effect on Performance | Increased hardness reduces abrasion but lowers flexibility | High elasticity improves energy absorption and durability |

Understanding Rubber: Defining Hardness and Elasticity

Rubber hardness measures resistance to indentation, typically defined by Shore A or Shore D scales, while elasticity reflects its ability to return to original shape after deformation, characterized by tensile elongation and modulus. These properties directly affect rubber performance in applications such as seals, tires, and vibration dampening materials. Understanding the balance between hardness and elasticity is crucial for selecting rubber compounds optimized for durability, flexibility, and wear resistance.

How Hardness Influences Rubber Performance

Rubber hardness significantly impacts its elasticity, with harder rubber compounds exhibiting reduced flexibility while providing greater resistance to wear and deformation. Increased hardness enhances durability and load-bearing capacity, making it suitable for applications requiring rigid, abrasion-resistant materials. However, excessive hardness may compromise the rubber's ability to absorb shocks and deform elastically, limiting performance in dynamic environments.

The Role of Elasticity in Rubber Applications

Elasticity in rubber determines its ability to return to its original shape after deformation, which is crucial in applications requiring flexibility and durability. High elasticity ensures efficient energy absorption and resistance to permanent deformation, making rubber ideal for seals, gaskets, and vibration dampening components. Hardness affects the surface resistance but does not directly influence the rubber's ability to stretch and recover, highlighting elasticity as the primary factor in performance-driven rubber products.

Measuring Hardness in Rubber Materials

Measuring hardness in rubber materials is commonly done using the Shore durometer scale, specifically Shore A for softer rubbers and Shore D for harder variants. The durometer test gauges material resistance to indentation, providing a quantitative value that correlates inversely with elasticity; higher hardness values indicate lower elasticity and increased stiffness. Accurate hardness measurement is critical in applications such as automotive seals and footwear soles, where precise balance between durability and flexibility ensures optimal performance.

Methods for Assessing Rubber Elasticity

Rubber elasticity is commonly assessed through tensile testing, which measures elongation and recovery to determine elastic modulus and resilience. Dynamic mechanical analysis (DMA) evaluates the viscoelastic behavior by applying oscillatory stress, providing insights into hardness and elasticity under varying temperatures. Shore hardness tests, particularly Shore A and Shore D, indirectly relate to elasticity by quantifying surface resistance to indentation, complementing data from mechanical and thermal assessments.

Balancing Hardness and Elasticity: Key Considerations

Balancing hardness and elasticity in rubber materials involves optimizing Shore hardness to ensure durability while maintaining sufficient elongation at break for flexibility. Harder rubber compounds often exhibit reduced elasticity, impacting resilience and impact resistance, making ingredient formulation critical to achieve desired performance. Engineers must consider specific application requirements such as load-bearing capacity and deformation recovery to select the ideal hardness-elasticity balance.

Impact of Rubber Formulation on Hardness and Elasticity

Rubber formulation significantly impacts its hardness and elasticity by altering the polymer composition and crosslink density. Increasing filler content or crosslinking agents enhances hardness but reduces elasticity, making the material stiffer and less flexible. Conversely, formulations with lower filler levels and optimized polymer chains maintain higher elasticity while providing sufficient hardness for specific applications.

Choosing the Right Hardness for Specific Rubber Uses

Selecting the appropriate hardness level is crucial for maximizing rubber's elasticity in specific applications, as softer compounds provide greater flexibility and impact resistance, while harder rubbers offer improved wear resistance and load-bearing capacity. Industrial seals and gaskets typically require moderate hardness to maintain elasticity under pressure and temperature variations, ensuring effective sealing without cracking. For tire treads and conveyor belts, higher hardness enhances durability and abrasion resistance, balancing elasticity to maintain grip and flexibility.

How Temperature Affects Hardness and Elasticity in Rubber

Temperature significantly influences the hardness and elasticity of rubber, with increased heat generally reducing hardness while enhancing elasticity by making the polymer chains more flexible. At lower temperatures, rubber becomes harder and less elastic due to restricted molecular motion, which can lead to brittleness and decreased performance. Understanding this temperature-dependent behavior is essential for applications requiring consistent mechanical properties across varying environmental conditions.

Real-World Examples: Hardness vs Elasticity in Rubber Products

Hardness and elasticity in rubber products significantly influence their performance in real-world applications, such as tires and seals. Tire treads require a balanced hardness to resist wear while maintaining elasticity for traction and shock absorption. Seals and gaskets prioritize higher elasticity to ensure tight fits and prevent leaks, despite varying hardness levels.

Hardness vs Elasticity Infographic

materialdif.com

materialdif.com