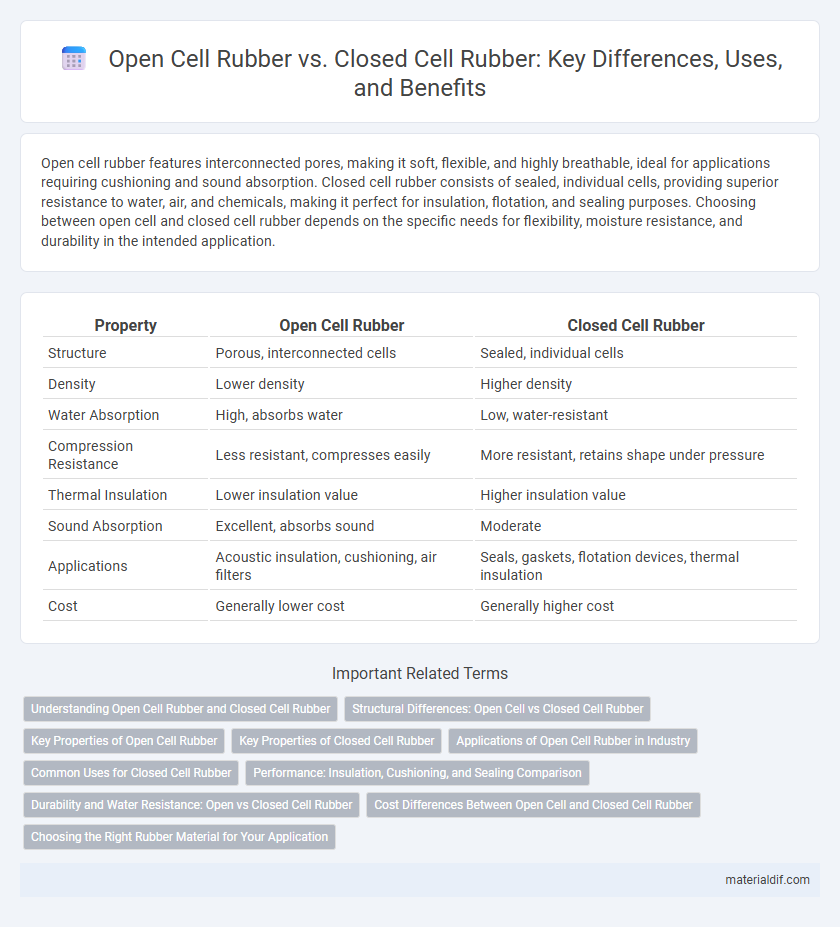

Open cell rubber features interconnected pores, making it soft, flexible, and highly breathable, ideal for applications requiring cushioning and sound absorption. Closed cell rubber consists of sealed, individual cells, providing superior resistance to water, air, and chemicals, making it perfect for insulation, flotation, and sealing purposes. Choosing between open cell and closed cell rubber depends on the specific needs for flexibility, moisture resistance, and durability in the intended application.

Table of Comparison

| Property | Open Cell Rubber | Closed Cell Rubber |

|---|---|---|

| Structure | Porous, interconnected cells | Sealed, individual cells |

| Density | Lower density | Higher density |

| Water Absorption | High, absorbs water | Low, water-resistant |

| Compression Resistance | Less resistant, compresses easily | More resistant, retains shape under pressure |

| Thermal Insulation | Lower insulation value | Higher insulation value |

| Sound Absorption | Excellent, absorbs sound | Moderate |

| Applications | Acoustic insulation, cushioning, air filters | Seals, gaskets, flotation devices, thermal insulation |

| Cost | Generally lower cost | Generally higher cost |

Understanding Open Cell Rubber and Closed Cell Rubber

Open cell rubber features interconnected pores that allow air and moisture to pass through, making it softer, more flexible, and better suited for cushioning and insulation where breathability is essential. Closed cell rubber consists of sealed, air-filled cells that provide higher density, superior water resistance, and excellent thermal insulation, commonly used for sealing, flotation, and shock absorption applications. Understanding the differences between open cell and closed cell rubber helps in selecting the right material based on properties like durability, compression resistance, and environmental exposure.

Structural Differences: Open Cell vs Closed Cell Rubber

Open cell rubber features interconnected pores allowing air and moisture to pass through, resulting in a softer, more flexible texture ideal for cushioning and sound absorption. Closed cell rubber contains sealed, individual cells filled with gas, providing higher density, water resistance, and superior insulation against gases and liquids. The structural difference between open cell and closed cell rubber directly impacts their applications, with open cell preferred for breathability and closed cell favored for durability and moisture barrier properties.

Key Properties of Open Cell Rubber

Open cell rubber features interconnected pores that allow air and moisture to pass through, resulting in excellent breathability and flexibility. Its lower density and softer texture provide superior cushioning and sound absorption compared to closed cell rubber. Key properties include high permeability, lightweight structure, and enhanced compression set resistance, making it ideal for applications requiring airflow and impact damping.

Key Properties of Closed Cell Rubber

Closed cell rubber features a dense, impermeable structure that provides superior resistance to water, air, and chemical infiltration compared to open cell rubber. Its high compressive strength and excellent thermal insulation properties make it ideal for applications requiring durability and moisture resistance. The closed cells trap gas, resulting in enhanced buoyancy and soundproofing benefits.

Applications of Open Cell Rubber in Industry

Open cell rubber is widely used in industries requiring cushioning, sound absorption, and filtration due to its porous structure that allows air and liquids to pass through. Common applications include seals, gaskets, insulating layers in HVAC systems, and packaging materials where flexibility and breathability are crucial. Its ability to conform to surfaces makes it ideal for vibration dampening in automotive and electronic equipment manufacturing.

Common Uses for Closed Cell Rubber

Closed cell rubber is commonly used in applications requiring superior insulation and resistance to water, chemicals, and impact, such as gaskets, seals, automotive door and window trim, and marine flotation devices. Its dense structure prevents air and moisture infiltration, making it ideal for weather stripping, soundproofing, and vibration dampening in construction and industrial settings. Closed cell foam is also preferred in medical devices and protective packaging due to its cushioning properties and durability.

Performance: Insulation, Cushioning, and Sealing Comparison

Open cell rubber features interconnected pores that allow air and moisture to pass through, providing excellent cushioning but limited insulation and sealing capabilities. Closed cell rubber consists of tightly packed, air-filled cells, delivering superior thermal insulation, higher resistance to water and air penetration, and enhanced sealing performance. For applications requiring robust insulation and airtight sealing, closed cell rubber offers a significant advantage over open cell variants, while open cell rubber excels in shock absorption and breathability.

Durability and Water Resistance: Open vs Closed Cell Rubber

Closed cell rubber offers superior durability and water resistance due to its tightly packed cells that prevent water absorption and resist physical wear. Open cell rubber, while more flexible and compressible, tends to absorb water and degrade faster when exposed to moisture and harsh conditions. This structural difference makes closed cell rubber ideal for long-term sealing and insulation applications where durability and water resistance are critical.

Cost Differences Between Open Cell and Closed Cell Rubber

Open cell rubber tends to be less expensive due to its lower density and simpler manufacturing process compared to closed cell rubber, which is denser and more complex to produce. Closed cell rubber provides superior insulation and moisture resistance, often justifying its higher cost for applications requiring durability and environmental protection. Budget constraints often drive the choice towards open cell rubber, especially in projects where cost-efficiency outweighs performance needs.

Choosing the Right Rubber Material for Your Application

Open cell rubber offers excellent breathability and cushioning, making it ideal for applications requiring sound absorption and lightweight insulation. Closed cell rubber provides superior moisture resistance, density, and durability, suitable for sealing, buoyancy, and impact protection in harsh environments. Assessing factors like exposure to water, compression needs, and environmental conditions ensures the optimal choice between open and closed cell rubber materials.

Open Cell Rubber vs Closed Cell Rubber Infographic

materialdif.com

materialdif.com