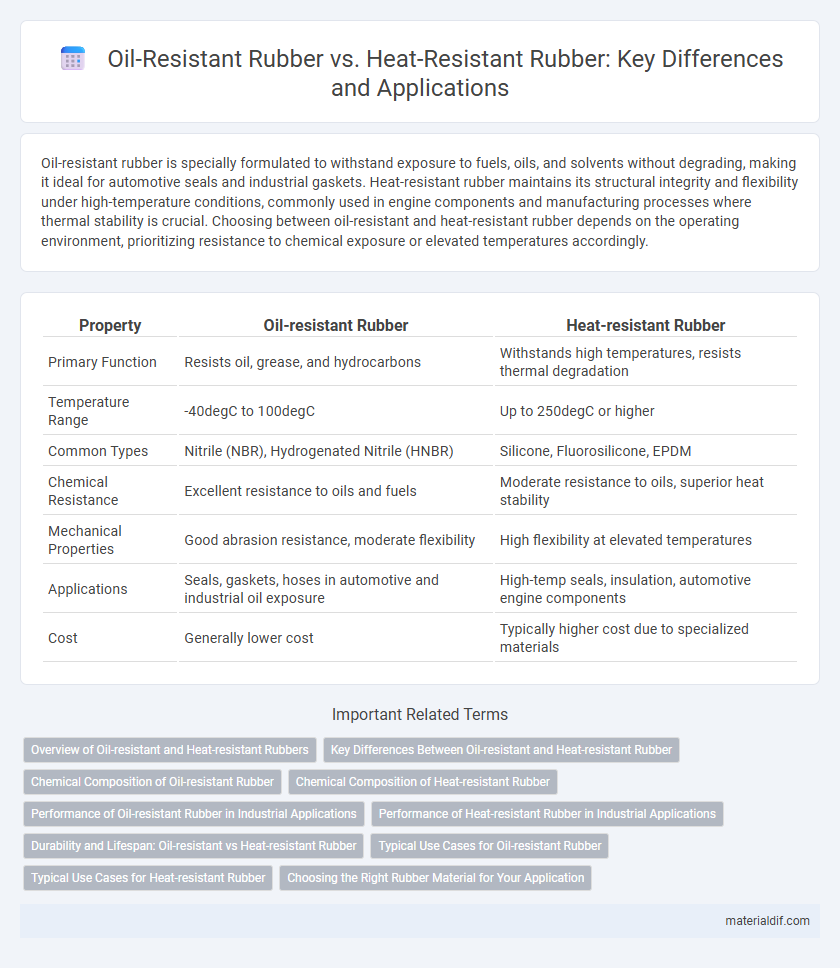

Oil-resistant rubber is specially formulated to withstand exposure to fuels, oils, and solvents without degrading, making it ideal for automotive seals and industrial gaskets. Heat-resistant rubber maintains its structural integrity and flexibility under high-temperature conditions, commonly used in engine components and manufacturing processes where thermal stability is crucial. Choosing between oil-resistant and heat-resistant rubber depends on the operating environment, prioritizing resistance to chemical exposure or elevated temperatures accordingly.

Table of Comparison

| Property | Oil-resistant Rubber | Heat-resistant Rubber |

|---|---|---|

| Primary Function | Resists oil, grease, and hydrocarbons | Withstands high temperatures, resists thermal degradation |

| Temperature Range | -40degC to 100degC | Up to 250degC or higher |

| Common Types | Nitrile (NBR), Hydrogenated Nitrile (HNBR) | Silicone, Fluorosilicone, EPDM |

| Chemical Resistance | Excellent resistance to oils and fuels | Moderate resistance to oils, superior heat stability |

| Mechanical Properties | Good abrasion resistance, moderate flexibility | High flexibility at elevated temperatures |

| Applications | Seals, gaskets, hoses in automotive and industrial oil exposure | High-temp seals, insulation, automotive engine components |

| Cost | Generally lower cost | Typically higher cost due to specialized materials |

Overview of Oil-resistant and Heat-resistant Rubbers

Oil-resistant rubbers, such as nitrile (NBR) and fluoroelastomers (FKM), offer excellent resistance to petroleum products and hydrocarbons, making them ideal for applications in automotive seals, fuel hoses, and industrial gaskets. Heat-resistant rubbers like silicone and fluorosilicone withstand continuous temperatures up to 200-250degC, providing durability in high-heat environments such as engine components and electrical insulation. Both types contribute to enhanced equipment longevity by addressing specific operational challenges--in chemical exposure for oil-resistant rubbers and thermal stability for heat-resistant variants.

Key Differences Between Oil-resistant and Heat-resistant Rubber

Oil-resistant rubber is specifically formulated to withstand exposure to petroleum-based products, exhibiting strong resistance to oils, fuels, and solvents, making it ideal for automotive and industrial seals. Heat-resistant rubber, on the other hand, maintains its physical integrity and elasticity at elevated temperatures, typically ranging from 150degC to 300degC, suitable for applications in engine components and high-temperature gaskets. The key differences lie in their chemical composition and performance under environmental stress: oil-resistant rubber emphasizes hydrocarbon resistance, while heat-resistant rubber prioritizes thermal stability.

Chemical Composition of Oil-resistant Rubber

Oil-resistant rubber is primarily composed of nitrile butadiene rubber (NBR), which contains acrylonitrile monomers providing strong resistance to oils, fuels, and hydrocarbons. Its polymer structure features polar nitrile groups that enhance chemical affinity and durability against oil-based substances. This composition contrasts with heat-resistant rubber types, which rely on polymers like silicone or fluorocarbon for thermal stability rather than chemical resistance.

Chemical Composition of Heat-resistant Rubber

Heat-resistant rubber typically contains silicone or fluorocarbon polymers, which provide superior thermal stability by maintaining elasticity and structural integrity at elevated temperatures. These chemical compositions allow heat-resistant rubber to withstand continuous exposure to temperatures ranging from 200degC to 300degC, unlike oil-resistant rubber, which primarily incorporates polychloroprene or nitrile butadiene with additives targeting hydrocarbon and oil resistance rather than high heat. The presence of strong carbon-fluorine bonds in fluorocarbon rubber enhances its resistance to thermal degradation and chemical attack, making it ideal for industrial applications requiring prolonged heat exposure.

Performance of Oil-resistant Rubber in Industrial Applications

Oil-resistant rubber exhibits exceptional durability and chemical resistance, making it ideal for industrial applications involving exposure to petroleum-based oils, fuels, and lubricants. Its molecular structure prevents swelling and degradation, ensuring prolonged service life in harsh environments such as automotive seals, gaskets, and oil handling equipment. This rubber type maintains flexibility and mechanical integrity under continuous oil exposure, reducing maintenance costs and increasing operational efficiency.

Performance of Heat-resistant Rubber in Industrial Applications

Heat-resistant rubber demonstrates exceptional thermal stability, maintaining elasticity and mechanical strength at elevated temperatures up to 300degC, making it ideal for industrial applications such as automotive engines, furnace seals, and electrical insulation. Its superior resistance to oxidation, thermal degradation, and steam exposure ensures long-lasting performance even in harsh conditions, outperforming oil-resistant rubber, which primarily focuses on chemical and hydrocarbon resistance. Industries leverage heat-resistant rubber for critical components that require durability under continuous high heat, reducing maintenance costs and enhancing equipment safety.

Durability and Lifespan: Oil-resistant vs Heat-resistant Rubber

Oil-resistant rubber exhibits superior durability in environments exposed to petroleum-based substances, maintaining elasticity and structural integrity despite prolonged oil contact. Heat-resistant rubber withstands elevated temperatures without significant degradation, ensuring extended lifespan in high-thermal applications such as automotive engines and industrial machinery. Comparing both, oil-resistant rubber excels in chemical resilience, while heat-resistant rubber offers enhanced durability under thermal stress, making material selection dependent on specific operating conditions.

Typical Use Cases for Oil-resistant Rubber

Oil-resistant rubber is commonly used in automotive seals, gaskets, and hoses where exposure to fuels, lubricants, and hydraulic oils is frequent. This type of rubber maintains flexibility and durability in environments containing petroleum-based fluids, preventing degradation and leaks. Typical applications include engine compartments, fuel system components, and industrial machinery requiring resistance to oil and grease.

Typical Use Cases for Heat-resistant Rubber

Heat-resistant rubber is commonly used in automotive engine components, industrial gaskets, and electrical insulation where exposure to high temperatures is frequent. Its ability to maintain flexibility and insulation properties at elevated temperatures makes it ideal for exhaust hoses, seals in furnaces, and heat shields. Applications requiring durability under continuous heat stress benefit significantly from heat-resistant rubber's thermal stability.

Choosing the Right Rubber Material for Your Application

Oil-resistant rubber, such as nitrile (NBR) and fluorocarbon (FKM), offers excellent resistance to petroleum-based oils and fuels, making it ideal for automotive seals and fuel system components. Heat-resistant rubber, including silicone (VMQ) and fluorosilicone, maintains flexibility and durability at elevated temperatures, suitable for high-temperature gaskets and electrical insulation. Selecting the right rubber depends on specific environmental factors like temperature range, chemical exposure, and mechanical stress to ensure performance and longevity.

Oil-resistant Rubber vs Heat-resistant Rubber Infographic

materialdif.com

materialdif.com