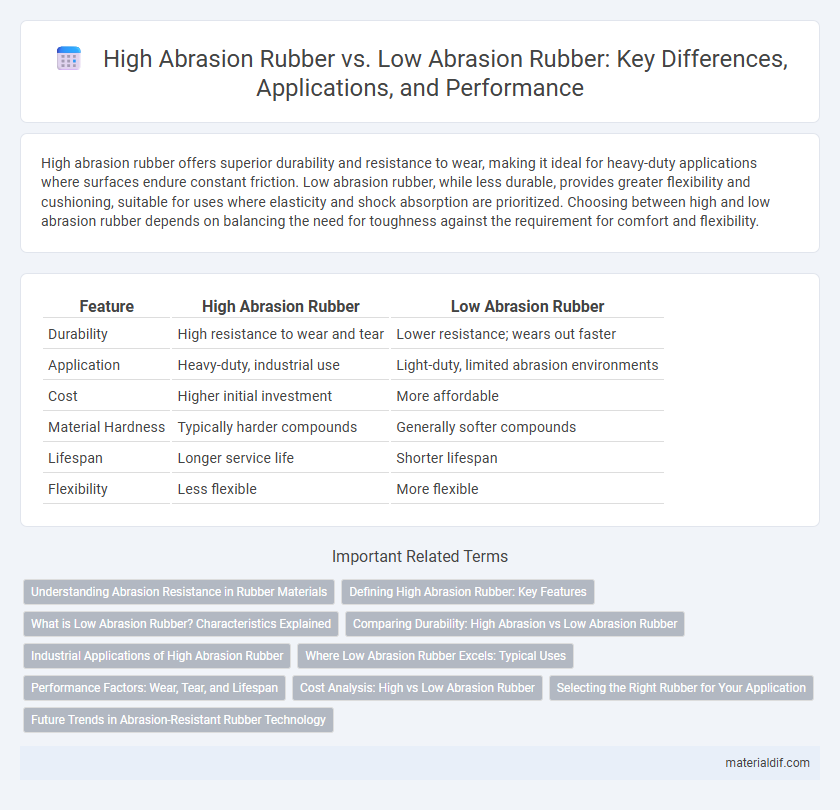

High abrasion rubber offers superior durability and resistance to wear, making it ideal for heavy-duty applications where surfaces endure constant friction. Low abrasion rubber, while less durable, provides greater flexibility and cushioning, suitable for uses where elasticity and shock absorption are prioritized. Choosing between high and low abrasion rubber depends on balancing the need for toughness against the requirement for comfort and flexibility.

Table of Comparison

| Feature | High Abrasion Rubber | Low Abrasion Rubber |

|---|---|---|

| Durability | High resistance to wear and tear | Lower resistance; wears out faster |

| Application | Heavy-duty, industrial use | Light-duty, limited abrasion environments |

| Cost | Higher initial investment | More affordable |

| Material Hardness | Typically harder compounds | Generally softer compounds |

| Lifespan | Longer service life | Shorter lifespan |

| Flexibility | Less flexible | More flexible |

Understanding Abrasion Resistance in Rubber Materials

High abrasion rubber is engineered with enhanced resistance to surface wear, making it ideal for applications involving continuous friction and mechanical stress. Low abrasion rubber, while offering greater flexibility and softer textures, tends to wear down faster under abrasive conditions, limiting its use in heavy-duty environments. Understanding the abrasion resistance of rubber materials is crucial for selecting the right compound to maximize durability and performance in industrial and commercial applications.

Defining High Abrasion Rubber: Key Features

High abrasion rubber is engineered for exceptional durability, featuring a dense molecular structure and reinforced compounds that resist wear from continuous friction and mechanical stress. Its key features include superior tensile strength, enhanced tear resistance, and optimal hardness, making it ideal for demanding industrial applications such as conveyor belts, tires, and heavy machinery components. This rubber type significantly outperforms low abrasion rubber in lifespan and performance when exposed to harsh abrasive environments.

What is Low Abrasion Rubber? Characteristics Explained

Low abrasion rubber is a type of elastomer designed to resist surface wear and tear in low-friction environments, maintaining durability without excessive hardness. It typically features a softer composition, lower Shore hardness, and enhanced elasticity, making it ideal for applications requiring gentle contact and minimal material loss. Key characteristics include superior flexibility, excellent resistance to cutting or chipping, and a smooth surface finish that reduces friction and prolongs component life.

Comparing Durability: High Abrasion vs Low Abrasion Rubber

High abrasion rubber features enhanced resistance to wear, making it ideal for applications requiring prolonged durability under harsh conditions. Low abrasion rubber, while less resistant to surface wear, offers greater flexibility and cushioning, suitable for less demanding environments. Comparing durability, high abrasion rubber outperforms low abrasion types in lifespan and resilience, especially in abrasive industrial settings.

Industrial Applications of High Abrasion Rubber

High abrasion rubber is engineered to withstand extreme wear and tear, making it ideal for heavy-duty industrial applications such as conveyor belts, mining equipment, and heavy machinery components. Its enhanced durability significantly reduces maintenance costs and extends service life in environments involving constant friction and abrasive materials. Low abrasion rubber, by contrast, is better suited for applications requiring softer, less wear-resistant surfaces where flexibility and cushioning are prioritized.

Where Low Abrasion Rubber Excels: Typical Uses

Low abrasion rubber excels in applications requiring flexibility and impact resistance, such as conveyor belts in light-duty industries and protective coatings for machinery. Its resilience to surface wear makes it ideal for seals, gaskets, and vibration dampening components in automotive and aerospace sectors. This material's ability to maintain integrity under repeated stress supports its use in manufacturing flexible hoses and electrical insulation.

Performance Factors: Wear, Tear, and Lifespan

High abrasion rubber offers superior resistance to wear and tear, extending the lifespan of products exposed to harsh conditions and frequent friction. Low abrasion rubber, while more flexible, tends to degrade faster under continuous mechanical stress and abrasive environments. Selecting the appropriate abrasion rating directly impacts maintenance costs and operational efficiency in industrial applications.

Cost Analysis: High vs Low Abrasion Rubber

High abrasion rubber generally incurs higher initial costs due to its enhanced durability and resistance to wear, making it ideal for heavy-duty applications requiring longer service life. Low abrasion rubber, while more cost-effective upfront, often leads to increased maintenance expenses and more frequent replacement cycles in abrasive environments. Evaluating total cost of ownership reveals that high abrasion rubber can provide superior long-term value despite its premium price.

Selecting the Right Rubber for Your Application

High abrasion rubber offers superior resistance to wear and tear, making it ideal for applications involving heavy friction and impact, such as conveyor belts and mining equipment. Low abrasion rubber provides greater flexibility and cushioning, suitable for products requiring softer contact surfaces like gaskets and seals. Selecting the right rubber depends on the specific demands of the application, balancing durability with flexibility to optimize performance and lifespan.

Future Trends in Abrasion-Resistant Rubber Technology

High abrasion rubber technology is evolving with the integration of nanomaterials and advanced polymer blends that significantly enhance wear resistance and durability. Low abrasion rubber formulations are increasingly optimized for flexibility and energy efficiency, targeting applications requiring less intensive surface contact. Emerging trends emphasize sustainable materials and smart rubber compounds embedded with sensors for real-time wear monitoring, driving future innovation in abrasion-resistant rubber products.

High Abrasion Rubber vs Low Abrasion Rubber Infographic

materialdif.com

materialdif.com