Latex rubber is a natural, flexible material derived from the sap of rubber trees, known for its elasticity and water resistance, making it ideal for gloves and balloons. Solid rubber, produced through vulcanization of natural or synthetic rubber, offers greater durability and strength, suited for tires and industrial applications. Choosing between latex and solid rubber depends on the specific requirements of flexibility, resilience, and usage environment.

Table of Comparison

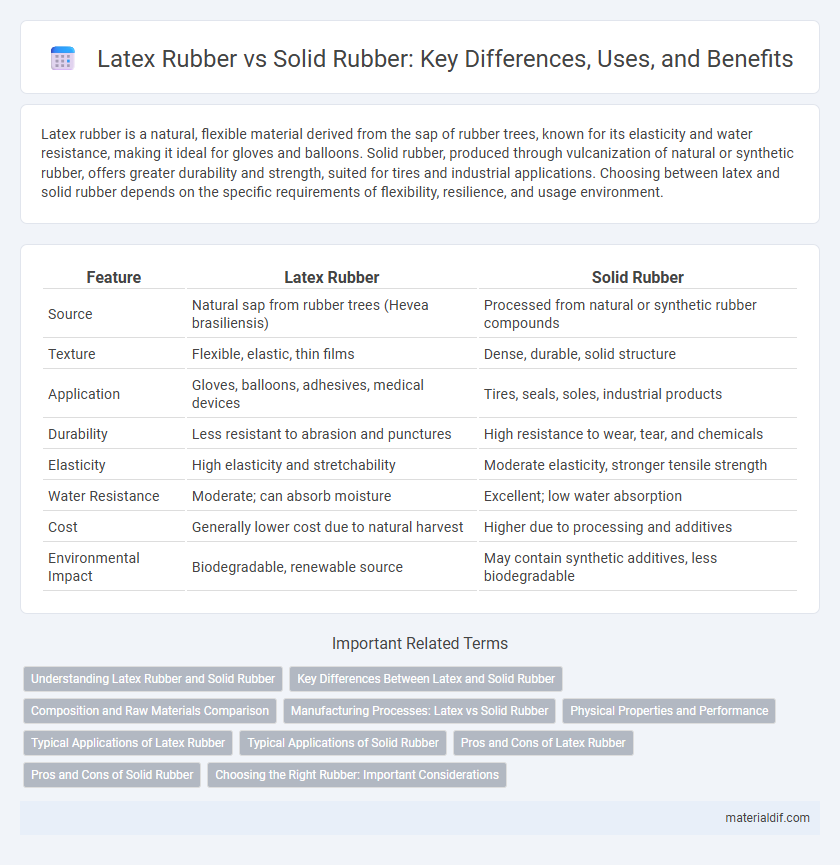

| Feature | Latex Rubber | Solid Rubber |

|---|---|---|

| Source | Natural sap from rubber trees (Hevea brasiliensis) | Processed from natural or synthetic rubber compounds |

| Texture | Flexible, elastic, thin films | Dense, durable, solid structure |

| Application | Gloves, balloons, adhesives, medical devices | Tires, seals, soles, industrial products |

| Durability | Less resistant to abrasion and punctures | High resistance to wear, tear, and chemicals |

| Elasticity | High elasticity and stretchability | Moderate elasticity, stronger tensile strength |

| Water Resistance | Moderate; can absorb moisture | Excellent; low water absorption |

| Cost | Generally lower cost due to natural harvest | Higher due to processing and additives |

| Environmental Impact | Biodegradable, renewable source | May contain synthetic additives, less biodegradable |

Understanding Latex Rubber and Solid Rubber

Latex rubber is a natural material derived from the sap of rubber trees, known for its elasticity, flexibility, and biodegradability, making it ideal for products like gloves and balloons. Solid rubber, in contrast, is typically vulcanized rubber processed into dense, durable sheets or molds that offer higher resistance to wear, chemicals, and temperature extremes, commonly used in tires, seals, and industrial applications. Understanding their differences in composition and properties helps determine the appropriate rubber type for specific manufacturing and performance requirements.

Key Differences Between Latex and Solid Rubber

Latex rubber is a natural, liquid form of rubber collected from rubber trees, renowned for its elasticity, flexibility, and ability to be molded into various shapes, making it ideal for products like gloves and balloons. Solid rubber, derived from latex through coagulation and vulcanization processes, possesses higher durability, resistance to abrasion, and structural strength, suited for tires, seals, and industrial applications. Key differences lie in their physical states, processing methods, and performance characteristics, with latex offering superior softness and stretch, while solid rubber excels in toughness and longevity.

Composition and Raw Materials Comparison

Latex rubber primarily consists of natural polymers harvested from the sap of rubber trees (Hevea brasiliensis), containing proteins, carbohydrates, and water, while solid rubber is a processed material derived from coagulated latex or synthetic sources like styrene-butadiene or nitrile. The composition of latex rubber retains its elastomeric properties with high elasticity and resilience due to its colloidal dispersion of polymer particles in water, whereas solid rubber undergoes vulcanization, enhancing strength, durability, and resistance to heat and chemicals. Raw material differences impact processing methods, with latex sourced directly from trees requiring minimal refinement compared to solid rubber that often combines natural rubber with fillers and additives for specific performance characteristics.

Manufacturing Processes: Latex vs Solid Rubber

Latex rubber is produced via a liquid phase process where natural or synthetic latex is collected, purified, and then vulcanized through centrifugation or coagulation, allowing for fine control over molecular composition and elasticity. Solid rubber manufacturing involves the processing of vulcanized rubber blocks or sheets through mechanical methods such as milling, extrusion, or molding, enabling the creation of dense, durable products with enhanced tensile strength. The differences in manufacturing impact the final material properties, with latex rubber offering flexibility and softness, while solid rubber provides robustness and resistance to wear.

Physical Properties and Performance

Latex rubber offers superior elasticity and flexibility compared to solid rubber, making it ideal for applications requiring high stretch and recovery, such as gloves and balloons. Solid rubber exhibits greater hardness, abrasion resistance, and tensile strength, which enhances durability in heavy-duty uses like tires and seals. The choice between latex and solid rubber depends on the balance between elasticity and mechanical robustness needed for specific industrial performance requirements.

Typical Applications of Latex Rubber

Latex rubber is predominantly used in applications requiring high elasticity, flexibility, and fine detail molding, such as gloves, balloons, and surgical tubing. Its excellent tensile strength and ability to stretch make it ideal for medical supplies, adhesives, and dipped goods. Unlike solid rubber, latex rubber's liquid form allows for precise molding and seamless coating applications in consumer and industrial products.

Typical Applications of Solid Rubber

Solid rubber is commonly used in automotive tires, industrial belts, and vibration isolation mounts due to its excellent durability and resistance to wear. It is also widely applied in manufacturing seals, gaskets, and shoe soles, where its high tensile strength and resilience provide long-lasting performance. The material's robustness makes it ideal for heavy-duty applications requiring consistent mechanical properties and resilience under stress.

Pros and Cons of Latex Rubber

Latex rubber offers exceptional elasticity, flexibility, and a smooth surface, making it ideal for applications requiring tight seals and cushioning, but it is prone to degradation from UV exposure and ozone. Its natural origin ensures biodegradability and excellent tensile strength, yet latex rubber can cause allergic reactions in sensitive individuals. Unlike solid rubber, which provides greater durability and resistance to harsh chemicals, latex's softness limits its use in heavy-duty industrial environments.

Pros and Cons of Solid Rubber

Solid rubber offers superior durability and abrasion resistance compared to latex rubber, making it ideal for heavy-duty applications such as industrial seals and tires. It performs well under high temperatures and mechanical stress but tends to be less flexible and heavier than latex rubber, limiting its use in applications requiring elasticity and softness. Solid rubber is also generally more resistant to environmental factors like ozone and UV exposure, but its production cost and weight can be higher than latex alternatives.

Choosing the Right Rubber: Important Considerations

Choosing the right rubber involves evaluating the differences between latex rubber and solid rubber, particularly their elasticity, durability, and cost-effectiveness. Latex rubber offers superior flexibility and is ideal for applications requiring high elasticity, while solid rubber provides enhanced strength and resistance to wear, making it suitable for heavy-duty environments. Consider factors such as environmental exposure, load requirements, and product lifespan to determine the most appropriate rubber type for specific industrial or consumer needs.

Latex Rubber vs Solid Rubber Infographic

materialdif.com

materialdif.com