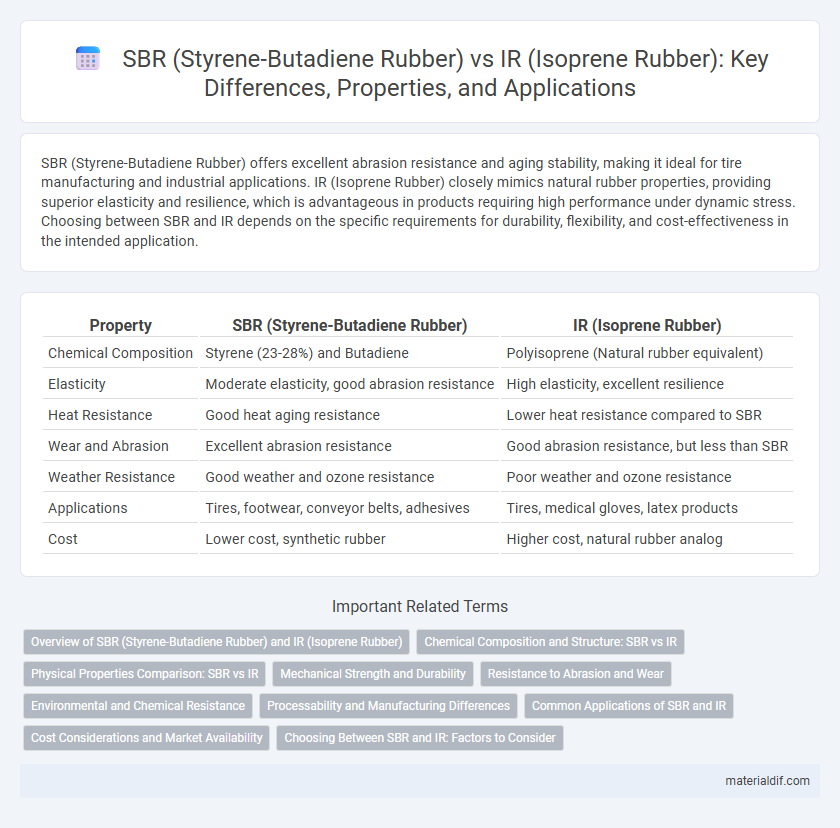

SBR (Styrene-Butadiene Rubber) offers excellent abrasion resistance and aging stability, making it ideal for tire manufacturing and industrial applications. IR (Isoprene Rubber) closely mimics natural rubber properties, providing superior elasticity and resilience, which is advantageous in products requiring high performance under dynamic stress. Choosing between SBR and IR depends on the specific requirements for durability, flexibility, and cost-effectiveness in the intended application.

Table of Comparison

| Property | SBR (Styrene-Butadiene Rubber) | IR (Isoprene Rubber) |

|---|---|---|

| Chemical Composition | Styrene (23-28%) and Butadiene | Polyisoprene (Natural rubber equivalent) |

| Elasticity | Moderate elasticity, good abrasion resistance | High elasticity, excellent resilience |

| Heat Resistance | Good heat aging resistance | Lower heat resistance compared to SBR |

| Wear and Abrasion | Excellent abrasion resistance | Good abrasion resistance, but less than SBR |

| Weather Resistance | Good weather and ozone resistance | Poor weather and ozone resistance |

| Applications | Tires, footwear, conveyor belts, adhesives | Tires, medical gloves, latex products |

| Cost | Lower cost, synthetic rubber | Higher cost, natural rubber analog |

Overview of SBR (Styrene-Butadiene Rubber) and IR (Isoprene Rubber)

SBR (Styrene-Butadiene Rubber) is a synthetic copolymer derived from styrene and butadiene, widely used for its abrasion resistance and aging stability, especially in tires and industrial products. IR (Isoprene Rubber) is a natural or synthetic polymer of isoprene, valued for its high elasticity, resilience, and excellent mechanical properties, commonly applied in gloves, footwear, and automotive seals. Both rubbers differ in chemical structure and performance characteristics, with SBR excelling in wear resistance and IR in tensile strength and flexibility.

Chemical Composition and Structure: SBR vs IR

Styrene-Butadiene Rubber (SBR) consists of copolymerized styrene and butadiene units, forming a synthetic rubber with amorphous, irregular chains contributing to good abrasion resistance and aging stability. Isoprene Rubber (IR) is a synthetic analog of natural rubber, composed primarily of cis-1,4-polyisoprene, featuring highly regular polymer chains that provide superior elasticity and tensile strength. The chemical structure of SBR includes random styrene and butadiene sequences, while IR has a uniform isoprene monomer sequence, influencing their distinct mechanical and chemical properties.

Physical Properties Comparison: SBR vs IR

Styrene-Butadiene Rubber (SBR) exhibits excellent abrasion resistance and aging stability, making it suitable for tire treads and industrial applications. Isoprene Rubber (IR), closely resembling natural rubber, offers superior elasticity, tensile strength, and resilience, essential for dynamic components requiring high flexibility. While SBR performs well under heat and ozone exposure, IR maintains better mechanical properties at low temperatures, highlighting the importance of application-specific selection.

Mechanical Strength and Durability

Styrene-Butadiene Rubber (SBR) offers superior abrasion resistance and better tensile strength compared to Isoprene Rubber (IR), making it ideal for applications requiring enhanced mechanical durability. Isoprene Rubber exhibits excellent resilience and elasticity but generally has lower resistance to wear and aging than SBR. The synthetic composition of SBR provides improved resistance to heat and oxidative degradation, contributing to longer service life under demanding mechanical conditions.

Resistance to Abrasion and Wear

SBR (Styrene-Butadiene Rubber) offers superior resistance to abrasion and wear compared to Isoprene Rubber (IR), making it ideal for applications requiring enhanced durability, such as tire treads and conveyor belts. The synthetic composition of SBR provides excellent toughness and resilience under frictional stress, whereas IR is more prone to surface degradation during prolonged mechanical contact. SBR's optimized molecular structure ensures longer service life in high-wear environments, outperforming natural-based IR in maintaining integrity under abrasive conditions.

Environmental and Chemical Resistance

Styrene-Butadiene Rubber (SBR) exhibits superior resistance to abrasion, aging, and various chemicals such as alkalis and acids compared to Isoprene Rubber (IR). IR, while offering excellent elasticity and resilience, tends to degrade faster when exposed to ozone, sunlight, and harsh chemicals, limiting its environmental durability. SBR's enhanced chemical resistance and weathering capabilities make it the preferred choice for outdoor applications and products requiring long-term exposure to harsh environments.

Processability and Manufacturing Differences

SBR (Styrene-Butadiene Rubber) offers superior processability compared to IR (Isoprene Rubber) due to its lower viscosity and better compatibility with carbon black, enabling faster mixing and easier extrusion in manufacturing. IR requires more precise temperature control during vulcanization because of its natural polymer structure, leading to longer curing times and increased production complexity. The synthetic nature of SBR allows for greater consistency in batch production, whereas IR's natural origin results in variable molecular weights impacting process stability.

Common Applications of SBR and IR

SBR (Styrene-Butadiene Rubber) is widely used in tire manufacturing, conveyor belts, and shoe soles due to its excellent abrasion resistance and aging stability. IR (Isoprene Rubber) is primarily used in the production of natural rubber gloves, adhesives, and medical devices because of its high elasticity and resilience. Both rubbers serve critical roles in automotive, industrial, and medical sectors, with SBR favored for durability and IR for flexibility.

Cost Considerations and Market Availability

SBR (Styrene-Butadiene Rubber) is generally more cost-effective than IR (Isoprene Rubber) due to its synthetic production process and widespread industrial use, leading to lower raw material expenses. Market availability of SBR is higher because of its extensive application in automotive tires, conveyor belts, and footwear, ensuring consistent demand and supply. In contrast, IR is pricier and less abundant, primarily reserved for specialty applications like high-performance tires and medical products, reflecting its natural-source dependency and limited production scale.

Choosing Between SBR and IR: Factors to Consider

Selecting between SBR and IR depends largely on specific application requirements such as abrasion resistance, elasticity, and cost-effectiveness. SBR offers superior wear resistance and aging properties, making it ideal for automotive tires and industrial products, whereas IR provides excellent elasticity and resilience suited for high-performance tires and flexible rubber goods. Consider environmental exposure, mechanical demands, and budget constraints to determine the optimal rubber type for enhancing durability and performance.

SBR (Styrene-Butadiene Rubber) vs IR (Isoprene Rubber) Infographic

materialdif.com

materialdif.com