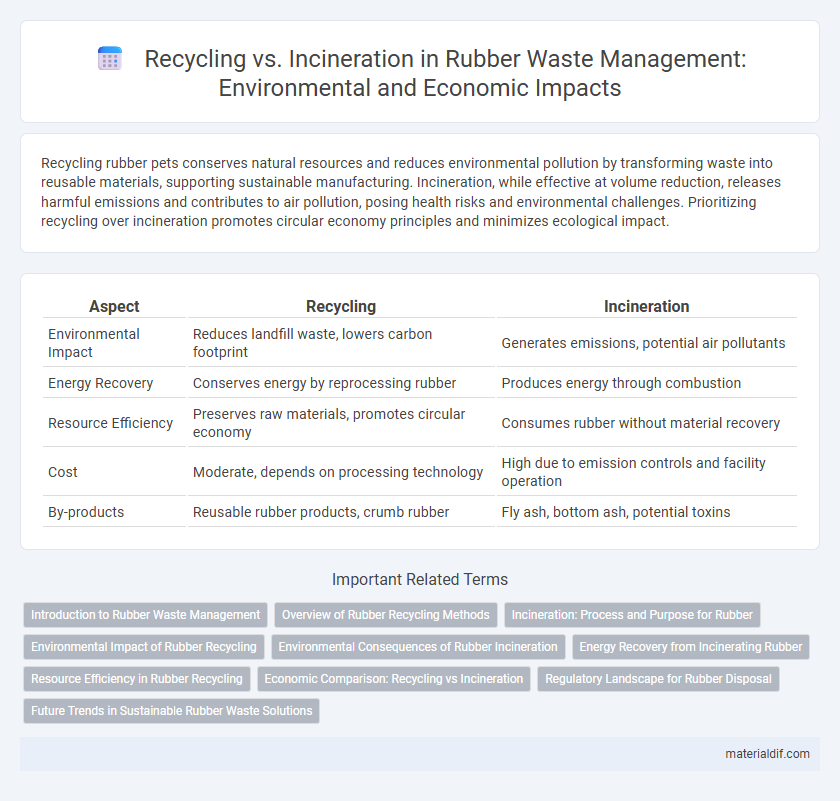

Recycling rubber pets conserves natural resources and reduces environmental pollution by transforming waste into reusable materials, supporting sustainable manufacturing. Incineration, while effective at volume reduction, releases harmful emissions and contributes to air pollution, posing health risks and environmental challenges. Prioritizing recycling over incineration promotes circular economy principles and minimizes ecological impact.

Table of Comparison

| Aspect | Recycling | Incineration |

|---|---|---|

| Environmental Impact | Reduces landfill waste, lowers carbon footprint | Generates emissions, potential air pollutants |

| Energy Recovery | Conserves energy by reprocessing rubber | Produces energy through combustion |

| Resource Efficiency | Preserves raw materials, promotes circular economy | Consumes rubber without material recovery |

| Cost | Moderate, depends on processing technology | High due to emission controls and facility operation |

| By-products | Reusable rubber products, crumb rubber | Fly ash, bottom ash, potential toxins |

Introduction to Rubber Waste Management

Rubber waste management involves two primary methods: recycling and incineration, each affecting environmental sustainability differently. Recycling processes recover valuable materials from used rubber, reducing landfill use and conserving natural resources. Incineration, while effective at waste volume reduction and energy recovery, poses challenges related to toxic emissions and requires advanced pollution control technologies.

Overview of Rubber Recycling Methods

Rubber recycling methods primarily include mechanical grinding, devulcanization, and pyrolysis, each designed to recover valuable materials from waste rubber products. Mechanical grinding transforms rubber into crumb rubber for reuse in asphalt, playground surfaces, and molded goods, while devulcanization chemically breaks sulfur bonds to restore rubber's original properties for new production. Pyrolysis thermally decomposes rubber waste into oil, gas, and char, offering energy recovery and material reuse but requires advanced technology to manage emissions effectively.

Incineration: Process and Purpose for Rubber

Incineration of rubber involves controlled combustion at high temperatures to convert waste rubber into energy, reducing landfill volume and recovering heat for power generation. This process effectively decomposes complex polymers in rubber, minimizing hazardous residues while capturing emissions through advanced filtration systems. Incineration serves as a waste-to-energy solution, complementing recycling by managing rubber materials unsuitable for mechanical reprocessing.

Environmental Impact of Rubber Recycling

Rubber recycling significantly reduces environmental pollution by decreasing landfill waste and lowering the need for raw material extraction, which conserves natural resources and reduces greenhouse gas emissions. Unlike incineration, which releases toxic pollutants such as dioxins and heavy metals into the atmosphere, recycling processes transform used rubber into reusable materials with minimal environmental footprint. Efficient rubber recycling supports a circular economy, enhancing sustainability and mitigating the adverse effects associated with rubber waste disposal.

Environmental Consequences of Rubber Incineration

Rubber incineration releases harmful pollutants such as dioxins, furans, and heavy metals, significantly impacting air quality and public health. Toxic emissions contribute to acid rain and respiratory issues, posing severe environmental hazards compared to rubber recycling, which conserves resources and reduces landfill waste. Recycling rubber also minimizes greenhouse gas emissions and conserves raw materials, making it a more sustainable alternative to incineration.

Energy Recovery from Incinerating Rubber

Incinerating rubber waste enables significant energy recovery, with the heat generated used to produce steam and electricity in waste-to-energy plants. Compared to recycling, which requires complex processing and may degrade material quality, incineration maximizes energy output from rubber's high calorific value, around 30-35 MJ/kg. This process reduces landfill volume and recovers valuable energy, contributing to sustainable waste management despite concerns about emissions requiring advanced filtration technologies.

Resource Efficiency in Rubber Recycling

Rubber recycling significantly enhances resource efficiency by recovering valuable materials such as synthetic polymers, carbon black, and steel, reducing the demand for virgin raw materials and minimizing environmental impact. Incineration, while useful for energy recovery, results in the loss of these reusable components and generates emissions that require stringent control measures. Emphasizing recycling in rubber waste management promotes circular economy principles, conserving natural resources and reducing landfill dependence.

Economic Comparison: Recycling vs Incineration

Recycling rubber reduces raw material costs by recovering valuable polymers and fillers, resulting in lower production expenses compared to incineration, which incurs energy generation costs without material recovery. The economic advantage of recycling is enhanced by government incentives and lower landfill fees, whereas incineration involves high operational and emission control costs. Market demand for recycled rubber products further boosts profitability, making recycling a more cost-effective and sustainable option than incineration.

Regulatory Landscape for Rubber Disposal

Regulatory frameworks for rubber disposal prioritize recycling due to environmental impact reduction and resource conservation, with agencies such as the EPA enforcing strict guidelines to limit landfill use and incineration emissions. Recycling mandates often include requirements for tire-derived products, promoting circular economy practices and minimizing hazardous waste generation. Incineration regulations focus on controlling toxic byproducts, necessitating advanced emission control technologies to comply with air quality standards and reduce public health risks.

Future Trends in Sustainable Rubber Waste Solutions

Recycling rubber waste reduces environmental impact by conserving resources and lowering landfill use, while incineration offers energy recovery but poses emission challenges. Future trends emphasize advanced pyrolysis and devulcanization techniques to enhance rubber recyclability and minimize harmful byproducts. Integration of circular economy principles and regulatory support is driving innovation in sustainable rubber waste management technologies.

Recycling vs Incineration Infographic

materialdif.com

materialdif.com