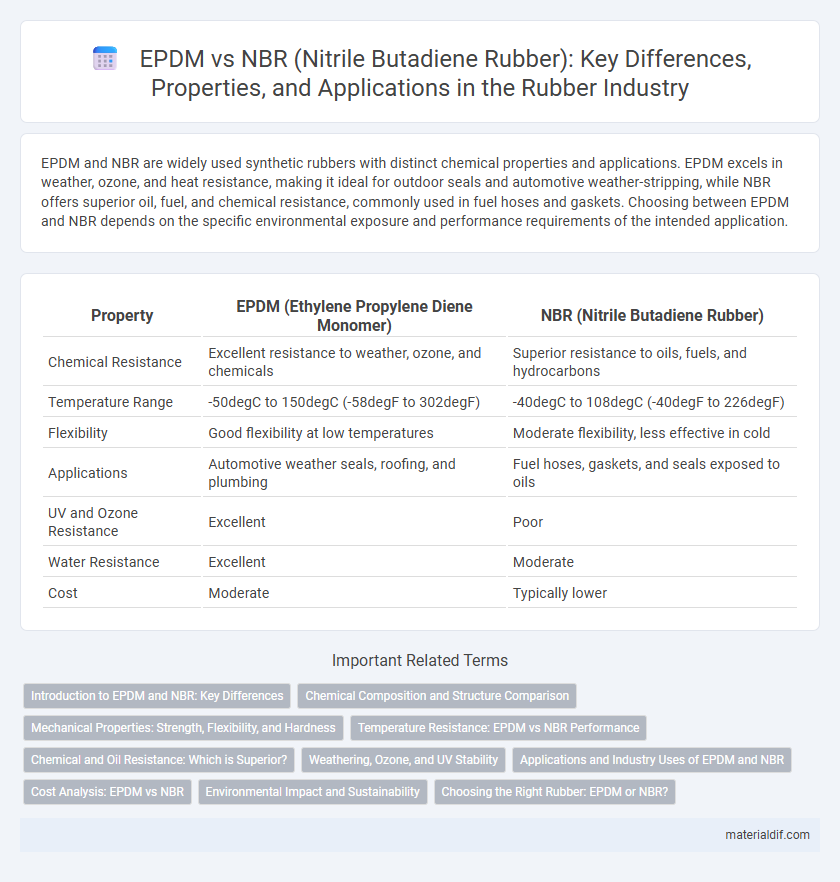

EPDM and NBR are widely used synthetic rubbers with distinct chemical properties and applications. EPDM excels in weather, ozone, and heat resistance, making it ideal for outdoor seals and automotive weather-stripping, while NBR offers superior oil, fuel, and chemical resistance, commonly used in fuel hoses and gaskets. Choosing between EPDM and NBR depends on the specific environmental exposure and performance requirements of the intended application.

Table of Comparison

| Property | EPDM (Ethylene Propylene Diene Monomer) | NBR (Nitrile Butadiene Rubber) |

|---|---|---|

| Chemical Resistance | Excellent resistance to weather, ozone, and chemicals | Superior resistance to oils, fuels, and hydrocarbons |

| Temperature Range | -50degC to 150degC (-58degF to 302degF) | -40degC to 108degC (-40degF to 226degF) |

| Flexibility | Good flexibility at low temperatures | Moderate flexibility, less effective in cold |

| Applications | Automotive weather seals, roofing, and plumbing | Fuel hoses, gaskets, and seals exposed to oils |

| UV and Ozone Resistance | Excellent | Poor |

| Water Resistance | Excellent | Moderate |

| Cost | Moderate | Typically lower |

Introduction to EPDM and NBR: Key Differences

EPDM (Ethylene Propylene Diene Monomer) rubber is a synthetic elastomer known for its excellent weather, ozone, and heat resistance, making it ideal for outdoor and automotive applications. NBR (Nitrile Butadiene Rubber) excels in oil, fuel, and chemical resistance, suited for sealing and industrial uses involving hydrocarbons. The key difference lies in EPDM's superior resistance to environmental factors versus NBR's enhanced compatibility with oils and fuels.

Chemical Composition and Structure Comparison

EPDM (Ethylene Propylene Diene Monomer) is a terpolymer consisting of ethylene, propylene, and a diene component, offering excellent resistance to heat, ozone, and weathering due to its saturated backbone structure. NBR (Nitrile Butadiene Rubber) is a copolymer of acrylonitrile and butadiene, characterized by its polar nitrile groups that provide superior resistance to oils, fuels, and chemicals but less resistance to ozone and heat compared to EPDM. The fundamental difference in chemical composition--saturation in EPDM versus unsaturation and polarity in NBR--directly affects their structural properties and suitability for specific industrial applications.

Mechanical Properties: Strength, Flexibility, and Hardness

EPDM rubber excels in flexibility and weather resistance with tensile strengths typically ranging from 7 to 14 MPa, making it ideal for applications requiring durability in outdoor environments. NBR (Nitrile Butadiene Rubber) offers superior oil and fuel resistance while maintaining higher hardness levels between 50 and 90 Shore A, along with tensile strengths from 10 to 25 MPa, providing enhanced mechanical strength for industrial sealing and automotive components. The hardness and flexibility trade-off between EPDM and NBR determines their suitability depending on the mechanical stress and environmental exposure in application-specific scenarios.

Temperature Resistance: EPDM vs NBR Performance

EPDM rubber exhibits superior temperature resistance, withstanding continuous exposure from -40degC to 150degC and short-term peaks up to 180degC, making it ideal for outdoor and high-heat environments. NBR typically performs well between -30degC and 100degC, but degrades at higher temperatures due to its lower thermal stability. Consequently, EPDM is preferred in applications requiring extended heat resistance, while NBR suits moderate temperature conditions with added oil resistance.

Chemical and Oil Resistance: Which is Superior?

EPDM (Ethylene Propylene Diene Monomer) exhibits excellent resistance to heat, oxidation, and weathering but has limited resistance to oils and hydrocarbons, making it less suitable for applications involving oil exposure. NBR (Nitrile Butadiene Rubber) offers superior resistance to petroleum-based oils, fuels, and other chemicals due to its polar nitrile groups, making it the preferred choice in automotive and industrial oil-resistant seals. The chemical structure of NBR provides enhanced oil resistance, while EPDM's non-polar structure limits its performance in oil-rich environments.

Weathering, Ozone, and UV Stability

EPDM rubber exhibits superior resistance to weathering, ozone, and UV exposure compared to NBR (Nitrile Butadiene Rubber), making it ideal for outdoor applications where long-term durability is essential. NBR is more susceptible to ozone cracking and UV degradation due to its lower unsaturation level in the polymer backbone. The unique ethylene-propylene structure in EPDM enhances oxidative stability, ensuring prolonged performance under harsh environmental conditions.

Applications and Industry Uses of EPDM and NBR

EPDM rubber excels in outdoor applications due to its superior resistance to weathering, ozone, and UV radiation, making it ideal for automotive seals, roofing membranes, and electrical insulation. NBR, with its excellent oil, fuel, and chemical resistance, is widely used in the automotive and oil industries for fuel hoses, gaskets, and seals. Both materials serve crucial roles in industrial manufacturing, but EPDM's weather durability and NBR's hydrocarbon resistance define their specific application advantages.

Cost Analysis: EPDM vs NBR

EPDM generally offers a lower cost of production compared to NBR due to its simpler polymerization process and abundant raw materials, making it a cost-effective choice for large-volume applications. In contrast, NBR incurs higher expenses stemming from specialized acrylonitrile content and more complex compounding requirements, impacting its overall price point. Long-term cost considerations also include EPDM's superior weathering and chemical resistance, which reduce maintenance and replacement costs relative to NBR in outdoor and automotive uses.

Environmental Impact and Sustainability

EPDM rubber demonstrates superior environmental sustainability due to its excellent resistance to weathering, ozone, and UV exposure, which extends product lifespan and reduces waste. NBR, while offering strong oil and fuel resistance, generally requires more energy-intensive production processes and contains synthetic components with higher environmental footprints. Choosing EPDM supports eco-friendly applications by minimizing degradation and emissions, aligning better with green manufacturing and circular economy goals.

Choosing the Right Rubber: EPDM or NBR?

EPDM rubber excels in weather resistance, ozone durability, and high-temperature stability, making it ideal for automotive seals and outdoor applications. NBR (Nitrile Butadiene Rubber) offers superior oil, fuel, and chemical resistance, preferred in fuel hoses, gaskets, and hydraulic system components. Selecting between EPDM and NBR depends on the operating environment: choose EPDM for exposure to heat and weather, and NBR for applications involving oils and fuels.

EPDM vs NBR (Nitrile Butadiene Rubber) Infographic

materialdif.com

materialdif.com