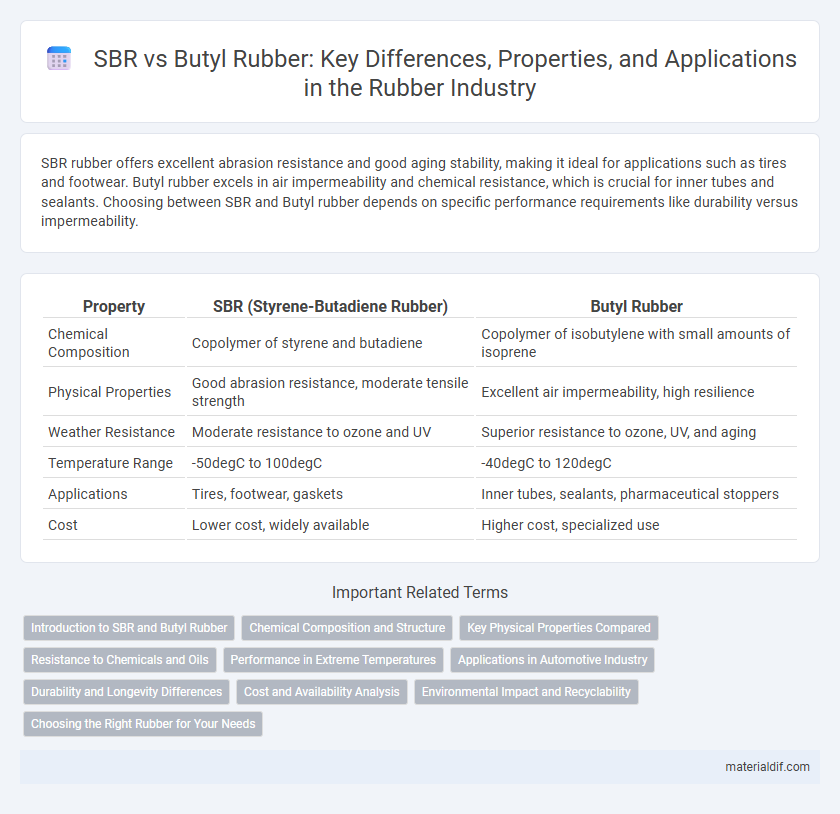

SBR rubber offers excellent abrasion resistance and good aging stability, making it ideal for applications such as tires and footwear. Butyl rubber excels in air impermeability and chemical resistance, which is crucial for inner tubes and sealants. Choosing between SBR and Butyl rubber depends on specific performance requirements like durability versus impermeability.

Table of Comparison

| Property | SBR (Styrene-Butadiene Rubber) | Butyl Rubber |

|---|---|---|

| Chemical Composition | Copolymer of styrene and butadiene | Copolymer of isobutylene with small amounts of isoprene |

| Physical Properties | Good abrasion resistance, moderate tensile strength | Excellent air impermeability, high resilience |

| Weather Resistance | Moderate resistance to ozone and UV | Superior resistance to ozone, UV, and aging |

| Temperature Range | -50degC to 100degC | -40degC to 120degC |

| Applications | Tires, footwear, gaskets | Inner tubes, sealants, pharmaceutical stoppers |

| Cost | Lower cost, widely available | Higher cost, specialized use |

Introduction to SBR and Butyl Rubber

SBR (Styrene-Butadiene Rubber) is a synthetic rubber widely used for tire manufacturing, footwear, and conveyor belts due to its excellent abrasion resistance and aging stability. Butyl rubber, composed primarily of isobutylene with a small amount of isoprene, offers exceptional impermeability to gases and superior vibration damping, making it ideal for inner tubes and sealants. Both rubbers serve distinct industrial applications thanks to their unique chemical structures and performance characteristics.

Chemical Composition and Structure

Styrene-Butadiene Rubber (SBR) consists of styrene and butadiene monomers, forming a synthetic copolymer with a predominantly amorphous structure, providing good abrasion resistance and elasticity. Butyl rubber is a copolymer of isobutylene with a small proportion of isoprene, characterized by its highly saturated backbone and minimal unsaturation, which imparts excellent impermeability and chemical resistance. The chemical composition of SBR results in higher reactivity and aging susceptibility, while butyl rubber's saturated structure enhances durability and resistance to heat and oxidation.

Key Physical Properties Compared

SBR (Styrene-Butadiene Rubber) offers excellent abrasion resistance and high tensile strength, making it ideal for tire manufacturing and footwear applications. Butyl rubber excels in impermeability to gases, superior flexibility at low temperatures, and excellent resistance to weathering and ozone, which suits it for inner tubes and sealants. Both rubbers show distinct hardness and elasticity profiles; SBR typically has higher hardness and better wear resistance, while butyl rubber provides exceptional air retention and damping properties.

Resistance to Chemicals and Oils

SBR (Styrene-Butadiene Rubber) shows moderate resistance to acids, alkalis, and some oils but tends to degrade when exposed to strong chemicals and petroleum-based oils. Butyl rubber, known for its superior chemical resistance, excels against a wide range of acids, alkalis, and oils, especially mineral oils and gasoline, making it ideal for applications requiring exposure to harsh substances. The molecular structure of butyl rubber provides excellent impermeability and durability, ensuring longer service life in chemically aggressive environments compared to SBR.

Performance in Extreme Temperatures

SBR (Styrene-Butadiene Rubber) maintains flexibility and abrasion resistance at moderate temperatures but tends to harden and lose elasticity below -40degC, limiting its use in extreme cold conditions. Butyl rubber excels in extreme temperature performance, retaining its elasticity and impermeability from -50degC up to 120degC, making it suitable for harsh climates and high-temperature applications. The superior thermal stability and weather resistance of Butyl rubber provide enhanced durability where SBR's performance may degrade.

Applications in Automotive Industry

SBR (Styrene-Butadiene Rubber) is widely used in automotive tires due to its excellent abrasion resistance and good aging stability, enhancing tire durability and performance. Butyl rubber, known for its superior air impermeability and resistance to heat and chemicals, is primarily used in inner tubes, tire liners, and seals within the automotive industry to maintain tire pressure and improve fuel efficiency. The combination of SBR for tread strength and Butyl for airtightness optimizes tire construction, contributing to safer and longer-lasting automotive components.

Durability and Longevity Differences

SBR rubber demonstrates moderate durability with resistance to abrasion and aging, making it suitable for applications requiring good wear performance but limited exposure to harsh environments. Butyl rubber excels in longevity due to its superior resistance to ozone, weathering, and chemical degradation, ensuring extended service life in demanding sealing and insulation uses. The inherent impermeability of butyl also contributes to its enhanced durability compared to SBR, especially in applications involving airtight or waterproof requirements.

Cost and Availability Analysis

SBR (Styrene-Butadiene Rubber) is generally more cost-effective and widely available due to its extensive industrial production and use in tire manufacturing, making it a preferred choice for high-volume applications. Butyl rubber, while offering superior impermeability and chemical resistance, is typically more expensive and less readily available because of its specialized production process and limited suppliers. Cost analysis reveals that SBR's lower price point and abundant supply make it suitable for budget-conscious projects, whereas Butyl rubber's premium cost is justified in applications requiring enhanced barrier properties.

Environmental Impact and Recyclability

SBR (Styrene-Butadiene Rubber) and Butyl rubber differ significantly in environmental impact and recyclability, with SBR being more widely recycled due to its higher compatibility with existing rubber recycling processes and its derivation from petroleum-based styrene and butadiene monomers. Butyl rubber, made from isobutylene and isoprene, exhibits superior impermeability and chemical resistance but presents greater challenges in recycling due to its cross-linked structure and limited compatibility with standard recycling technologies. Life cycle assessments reveal that SBR generally has a higher carbon footprint attributed to its production but benefits from established recycling infrastructure, whereas Butyl rubber's durability results in longer product lifetimes, reducing frequency of replacement but increasing end-of-life disposal complexity.

Choosing the Right Rubber for Your Needs

SBR (Styrene-Butadiene Rubber) offers excellent abrasion resistance and cost-effectiveness, making it ideal for automotive tires and industrial applications requiring durability. Butyl rubber provides superior impermeability and airtightness, suited for inner tubes, sealants, and pharmaceutical stoppers where low gas permeability is critical. Selecting between SBR and Butyl depends on balancing mechanical performance with chemical resistance and air retention requirements specific to the application.

SBR vs Butyl Rubber Infographic

materialdif.com

materialdif.com