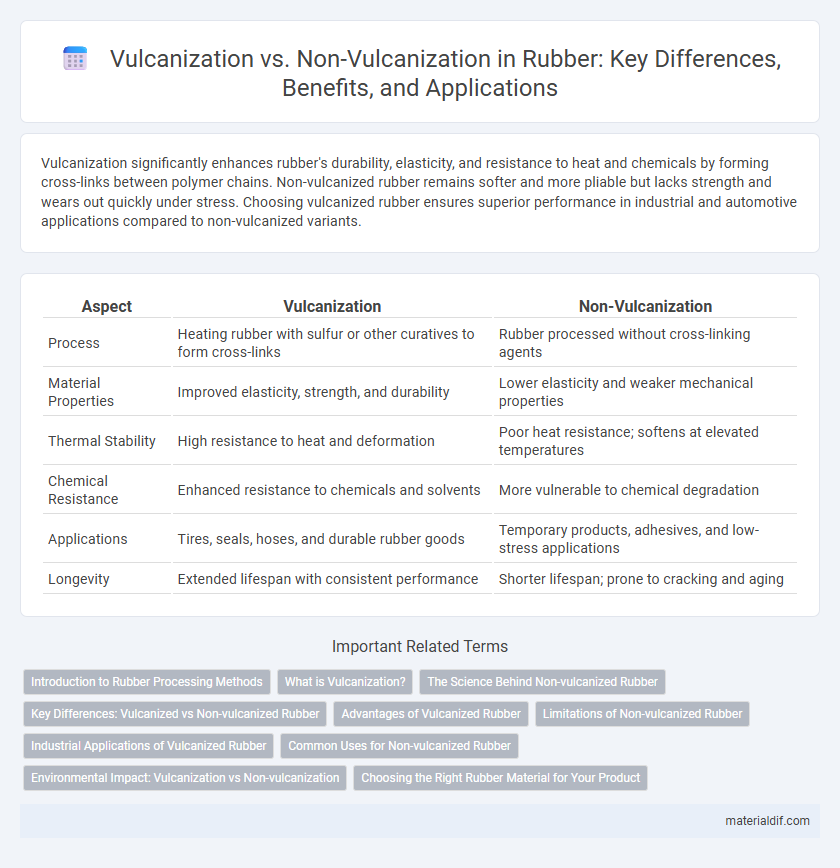

Vulcanization significantly enhances rubber's durability, elasticity, and resistance to heat and chemicals by forming cross-links between polymer chains. Non-vulcanized rubber remains softer and more pliable but lacks strength and wears out quickly under stress. Choosing vulcanized rubber ensures superior performance in industrial and automotive applications compared to non-vulcanized variants.

Table of Comparison

| Aspect | Vulcanization | Non-Vulcanization |

|---|---|---|

| Process | Heating rubber with sulfur or other curatives to form cross-links | Rubber processed without cross-linking agents |

| Material Properties | Improved elasticity, strength, and durability | Lower elasticity and weaker mechanical properties |

| Thermal Stability | High resistance to heat and deformation | Poor heat resistance; softens at elevated temperatures |

| Chemical Resistance | Enhanced resistance to chemicals and solvents | More vulnerable to chemical degradation |

| Applications | Tires, seals, hoses, and durable rubber goods | Temporary products, adhesives, and low-stress applications |

| Longevity | Extended lifespan with consistent performance | Shorter lifespan; prone to cracking and aging |

Introduction to Rubber Processing Methods

Vulcanization is a chemical process that enhances rubber by forming cross-links between polymer chains, significantly improving its elasticity, strength, and durability. In contrast, non-vulcanized rubber remains in its natural, softer state, which limits its mechanical properties and resistance to heat and abrasion. The choice between vulcanized and non-vulcanized rubber depends on the desired application, with vulcanization being essential for industrial uses requiring enhanced performance.

What is Vulcanization?

Vulcanization is a chemical process that enhances rubber's durability, elasticity, and strength by heating natural rubber with sulfur or other curatives, forming cross-links between polymer chains. This transformation significantly improves rubber's resistance to abrasion, temperature variations, and chemical exposure compared to non-vulcanized rubber, which remains soft, sticky, and less stable. Vulcanized rubber is widely used in tires, seals, and industrial products due to its superior mechanical properties and longevity.

The Science Behind Non-vulcanized Rubber

Non-vulcanized rubber consists primarily of natural polymers like polyisoprene that retain their original thermoplastic properties, making the material soft, sticky, and prone to deformation under heat. Without sulfur cross-linking, which is integral to vulcanization, the molecular chains in non-vulcanized rubber lack structural reinforcement, resulting in lower elasticity and mechanical strength. This absence of chemical cross-links causes non-vulcanized rubber to exhibit poor resistance to temperature variations, oxidation, and abrasion compared to its vulcanized counterpart.

Key Differences: Vulcanized vs Non-vulcanized Rubber

Vulcanized rubber undergoes a chemical process involving sulfur or other curatives that form cross-links between polymer chains, enhancing its strength, elasticity, and resistance to heat and chemicals. Non-vulcanized rubber remains in its raw or natural state, lacking these cross-links, resulting in a softer, more pliable material with lower durability and poorer resistance to environmental factors. The key differences lie in vulcanized rubber's improved mechanical properties and thermal stability compared to the limited performance and higher tackiness of non-vulcanized rubber.

Advantages of Vulcanized Rubber

Vulcanized rubber offers enhanced durability and elasticity compared to non-vulcanized rubber, providing superior resistance to abrasion, heat, and chemicals. This process significantly improves tensile strength and reduces tackiness, resulting in longer-lasting, more reliable rubber products. Vulcanization also enhances the rubber's ability to retain shape and performance under varying environmental conditions.

Limitations of Non-vulcanized Rubber

Non-vulcanized rubber exhibits poor mechanical strength, low elasticity, and significant deformation under stress, limiting its practical applications. It is highly susceptible to temperature fluctuations, becoming sticky at high temperatures and brittle in cold conditions. The lack of cross-linking in non-vulcanized rubber results in inferior durability and resistance to chemicals and wear compared to vulcanized rubber.

Industrial Applications of Vulcanized Rubber

Vulcanized rubber exhibits enhanced durability, heat resistance, and elasticity, making it indispensable in automotive tires, conveyor belts, and industrial seals where high performance under stress is critical. Its cross-linked molecular structure withstands mechanical wear and chemical exposure better than non-vulcanized rubber, ensuring longer service life in heavy-duty machinery and manufacturing equipment. Industrial applications rely on vulcanized rubber for vibration dampening, insulation, and pressure resistance, which are essential in aerospace, construction, and oil drilling sectors.

Common Uses for Non-vulcanized Rubber

Non-vulcanized rubber, often known as raw or natural rubber, is primarily used in applications where flexibility and tackiness are required, such as adhesives, chewing gum bases, and latex products like gloves and balloons. It remains soft and pliable, making it ideal for temporary uses or where further processing is anticipated. Unlike vulcanized rubber, it lacks the enhanced durability and heat resistance, limiting its role in high-performance industrial components.

Environmental Impact: Vulcanization vs Non-vulcanization

Vulcanization of rubber significantly improves material durability but involves chemicals like sulfur and accelerators that can generate hazardous waste and emissions, impacting soil and water quality. Non-vulcanized rubber production typically uses fewer additives, resulting in lower immediate environmental toxicity but produces softer, less durable products that contribute more quickly to waste accumulation. Choosing between vulcanized and non-vulcanized rubber involves balancing enhanced product lifespan and performance against potential chemical pollution risks and end-of-life environmental management challenges.

Choosing the Right Rubber Material for Your Product

Selecting the right rubber material hinges on understanding the differences between vulcanized and non-vulcanized rubber, as vulcanization enhances elasticity, durability, and heat resistance through sulfur cross-linking. Non-vulcanized rubber remains softer and less stable, suitable for temporary applications or products requiring high flexibility without long-term strength. For high-performance products exposed to heat, pressure, or wear, vulcanized rubber ensures longevity, while non-vulcanized rubber is ideal for cost-sensitive, low-stress uses.

Vulcanization vs Non-vulcanization Infographic

materialdif.com

materialdif.com