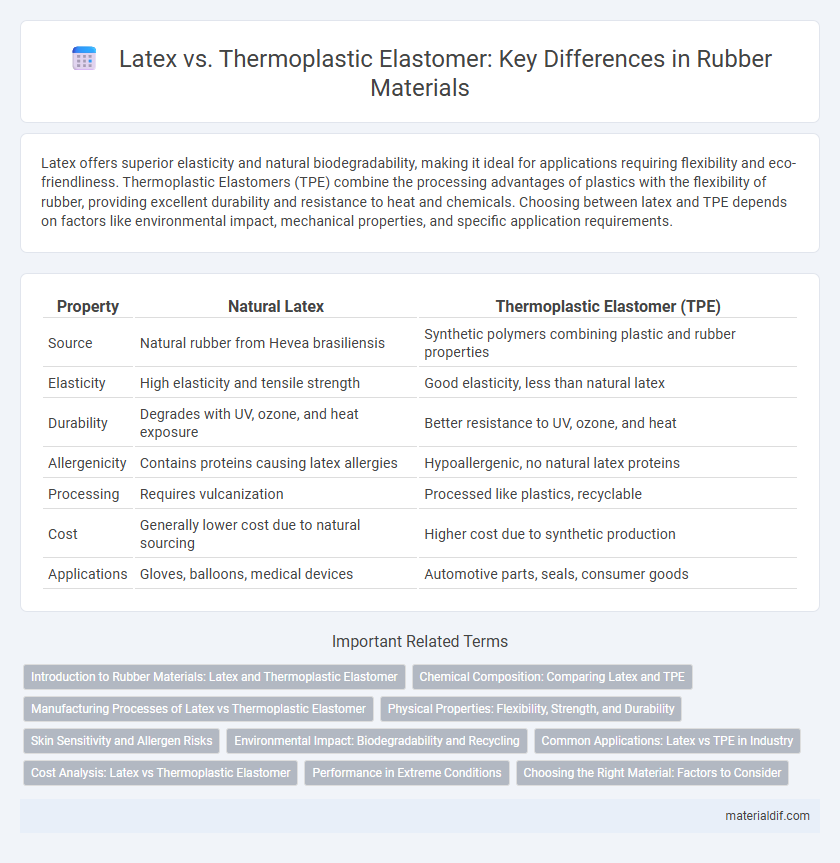

Latex offers superior elasticity and natural biodegradability, making it ideal for applications requiring flexibility and eco-friendliness. Thermoplastic Elastomers (TPE) combine the processing advantages of plastics with the flexibility of rubber, providing excellent durability and resistance to heat and chemicals. Choosing between latex and TPE depends on factors like environmental impact, mechanical properties, and specific application requirements.

Table of Comparison

| Property | Natural Latex | Thermoplastic Elastomer (TPE) |

|---|---|---|

| Source | Natural rubber from Hevea brasiliensis | Synthetic polymers combining plastic and rubber properties |

| Elasticity | High elasticity and tensile strength | Good elasticity, less than natural latex |

| Durability | Degrades with UV, ozone, and heat exposure | Better resistance to UV, ozone, and heat |

| Allergenicity | Contains proteins causing latex allergies | Hypoallergenic, no natural latex proteins |

| Processing | Requires vulcanization | Processed like plastics, recyclable |

| Cost | Generally lower cost due to natural sourcing | Higher cost due to synthetic production |

| Applications | Gloves, balloons, medical devices | Automotive parts, seals, consumer goods |

Introduction to Rubber Materials: Latex and Thermoplastic Elastomer

Latex is a natural rubber material derived from the sap of rubber trees, known for its excellent elasticity, biodegradability, and superior tactile properties. Thermoplastic elastomers (TPEs) are synthetic rubber-like materials combining the processing advantages of plastics with the flexibility of elastomers, offering enhanced chemical resistance and recyclability. Both materials serve distinct applications in automotive, medical, and consumer goods, with latex favored for natural cushioning and TPEs preferred for durability and design versatility.

Chemical Composition: Comparing Latex and TPE

Latex is a natural polymer derived from the sap of rubber trees, primarily composed of polyisoprene, which provides high elasticity and biodegradability. Thermoplastic elastomer (TPE), on the other hand, is a synthetic material made from a blend of polymers such as styrene blocks and rubber fractions, offering flexibility and recyclability. The chemical composition of latex allows for natural biodegradation, while TPE's synthetic structure enhances durability and processing versatility in various industrial applications.

Manufacturing Processes of Latex vs Thermoplastic Elastomer

Latex manufacturing involves the harvesting of natural rubber from Hevea brasiliensis trees, followed by processes such as coagulation, centrifugation, and vulcanization to create flexible rubber products. Thermoplastic elastomers (TPEs) are produced through polymerization and compounding techniques, which allow for melting and reshaping through injection molding or extrusion, providing efficient mass production. The critical distinction lies in latex's dependence on natural sources and chemical curing, whereas TPEs rely on synthetic polymers and thermoplastic processing for manufacturing versatility.

Physical Properties: Flexibility, Strength, and Durability

Latex exhibits superior flexibility and elasticity due to its natural polymer chains, providing excellent tensile strength and resilience under continuous stretching. Thermoplastic elastomers (TPEs) offer enhanced durability and resistance to environmental factors such as UV exposure and chemicals, while maintaining moderate flexibility and strength through their hybrid polymer structure. The selection between latex and TPE depends on the specific application requirements for flexibility, tensile strength, and long-term durability.

Skin Sensitivity and Allergen Risks

Latex, derived from natural rubber, contains proteins that can trigger allergic reactions and skin sensitivity in susceptible individuals. Thermoplastic elastomers (TPE), synthetically produced, typically present a lower risk of allergenicity and are often recommended for those with latex allergies. Choosing TPE products reduces exposure to latex proteins, minimizing the incidence of dermatitis and allergic contact reactions.

Environmental Impact: Biodegradability and Recycling

Latex, a natural rubber derived from rubber trees, is biodegradable and decomposes more rapidly in natural environments, reducing landfill accumulation and pollution. Thermoplastic elastomers (TPEs) are synthetic polymers that can be recycled through melting and reshaping, offering a closed-loop lifecycle but often require more energy and create microplastic waste when degraded. Choosing latex supports eco-friendly disposal due to its organic composition, whereas TPEs provide recycling benefits but pose challenges with long-term environmental persistence.

Common Applications: Latex vs TPE in Industry

Latex is widely used in medical gloves, balloons, and adhesives due to its natural elasticity and biodegradability, while thermoplastic elastomers (TPE) dominate automotive seals, consumer goods, and footwear applications because of their durability and recyclability. Latex provides superior tactile sensitivity and stretch, making it ideal for healthcare and hygiene products. TPE's resistance to chemicals and temperature variations suits industrial components and flexible packaging in diverse manufacturing sectors.

Cost Analysis: Latex vs Thermoplastic Elastomer

Latex generally offers a lower upfront material cost compared to thermoplastic elastomers (TPE), making it economically attractive for high-volume, low-complexity applications. However, TPEs provide cost benefits through enhanced durability, reusability, and ease of processing, reducing overall production and lifecycle expenses. The total cost analysis must consider factors such as raw material price volatility, processing technology, and application-specific performance requirements to determine the most cost-effective choice.

Performance in Extreme Conditions

Latex exhibits superior elasticity and natural resilience, maintaining flexibility under freezing and high-temperature conditions, making it ideal for extreme cold environments. Thermoplastic elastomers (TPE) offer enhanced chemical resistance and durability under UV exposure, performing reliably in harsh sunlight and corrosive environments. Both materials retain mechanical integrity under stress, but latex excels in bio-compatibility and rapid recovery, while TPE provides greater abrasion resistance and longer service life in oxidizing conditions.

Choosing the Right Material: Factors to Consider

Selecting between latex and thermoplastic elastomer (TPE) depends on factors such as elasticity requirements, chemical resistance, and intended application environment. Latex offers superior flexibility and biodegradability for products like gloves and balloons, while TPE provides enhanced durability, UV resistance, and ease of processing ideal for automotive seals and medical devices. Cost considerations and potential allergic reactions also influence the choice, with TPE being hypoallergenic and latex potentially causing sensitivities.

Latex vs Thermoplastic Elastomer Infographic

materialdif.com

materialdif.com