Thermoplastic Rubber (TPR) is a subset of Thermoplastic Elastomers (TPE) characterized by combining the properties of rubber with the processability of plastics, offering excellent flexibility and durability. TPE encompasses a broader range of materials, including styrenic block copolymers, thermoplastic vulcanizates, and thermoplastic polyolefins, providing diverse performance options for applications requiring elasticity and recyclability. Both TPR and TPE are used in industries such as automotive, footwear, and consumer goods, valued for their ability to be molded and reprocessed without vulcanization.

Table of Comparison

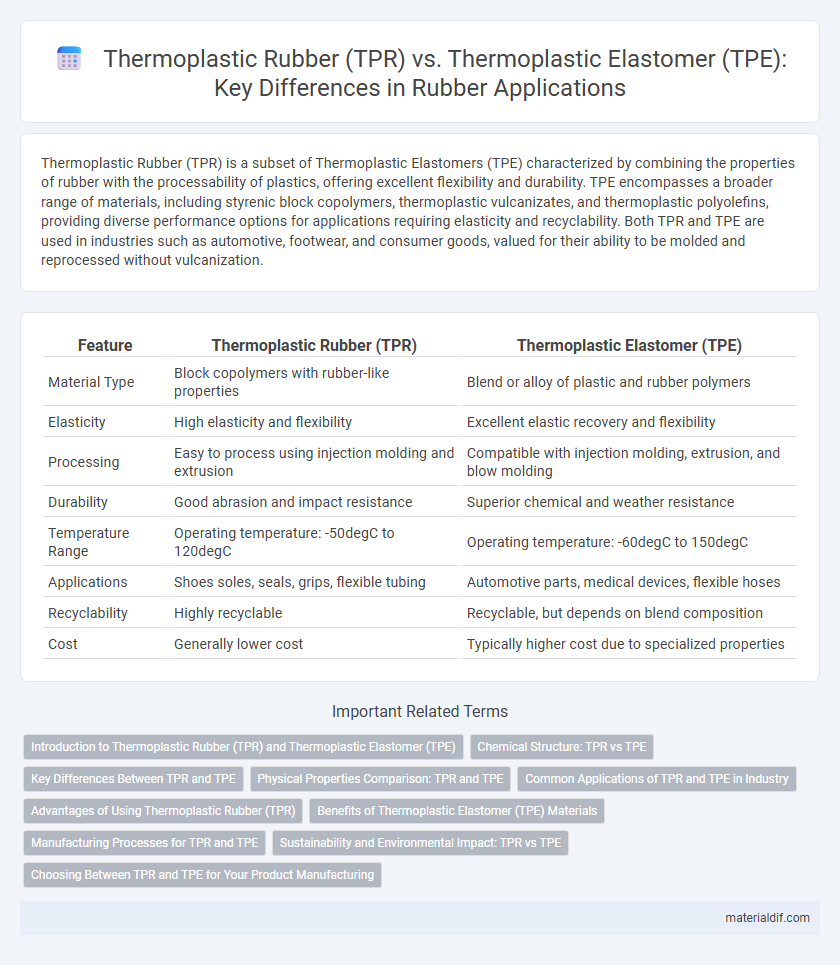

| Feature | Thermoplastic Rubber (TPR) | Thermoplastic Elastomer (TPE) |

|---|---|---|

| Material Type | Block copolymers with rubber-like properties | Blend or alloy of plastic and rubber polymers |

| Elasticity | High elasticity and flexibility | Excellent elastic recovery and flexibility |

| Processing | Easy to process using injection molding and extrusion | Compatible with injection molding, extrusion, and blow molding |

| Durability | Good abrasion and impact resistance | Superior chemical and weather resistance |

| Temperature Range | Operating temperature: -50degC to 120degC | Operating temperature: -60degC to 150degC |

| Applications | Shoes soles, seals, grips, flexible tubing | Automotive parts, medical devices, flexible hoses |

| Recyclability | Highly recyclable | Recyclable, but depends on blend composition |

| Cost | Generally lower cost | Typically higher cost due to specialized properties |

Introduction to Thermoplastic Rubber (TPR) and Thermoplastic Elastomer (TPE)

Thermoplastic Rubber (TPR) is a class of materials combining the properties of both rubber and thermoplastics, offering flexibility, durability, and easy processability. Thermoplastic Elastomer (TPE) encompasses a broader category of polymers that mimic rubber's elastic properties while being moldable like plastics, with variations such as styrenic block copolymers and thermoplastic vulcanizates. Both TPR and TPE are widely used in automotive, footwear, and consumer goods industries due to their recyclability and versatile performance characteristics.

Chemical Structure: TPR vs TPE

Thermoplastic Rubber (TPR) features a block copolymer structure with distinct hard and soft segments, providing elasticity through physical crosslinks rather than chemical bonds. Thermoplastic Elastomer (TPE) encompasses a broader category of copolymers, including styrenic block copolymers, polyolefin blends, and thermoplastic vulcanizates, characterized by their diverse chemical structures enabling rubber-like flexibility with thermoplastic processability. The key difference lies in TPR's simpler block copolymer arrangement versus TPE's varied chemical backbones offering tailored mechanical and thermal properties.

Key Differences Between TPR and TPE

Thermoplastic Rubber (TPR) is a subset of Thermoplastic Elastomers (TPE) that combines the properties of rubber with the processing advantages of plastics. TPR typically offers higher flexibility and rubber-like elasticity, while TPE encompasses a broader category with varied material compositions, including styrenic block copolymers, thermoplastic polyurethanes, and thermoplastic vulcanizates. Key differences lie in TPR's specific formulation for softness and resilience versus TPE's versatility in hardness, chemical resistance, and processing methods for diverse industrial applications.

Physical Properties Comparison: TPR and TPE

Thermoplastic Rubber (TPR) and Thermoplastic Elastomer (TPE) differ notably in their physical properties, with TPR exhibiting higher flexibility and excellent elastic recovery ideal for footwear soles and soft grips. TPE offers superior chemical resistance, heat resistance, and durability, making it suitable for automotive parts and medical devices. Both materials provide good processability and recyclability, but TPEs generally have a wider hardness range and better resistance to environmental factors.

Common Applications of TPR and TPE in Industry

Thermoplastic Rubber (TPR) is widely used in manufacturing shoe soles, flexible tubing, and automotive parts due to its excellent elasticity and durability. Thermoplastic Elastomer (TPE) finds common applications in medical devices, consumer electronics casings, and soft-touch grips, benefiting from its versatile processing and rubber-like flexibility. Both materials serve critical roles in industries requiring reusable and recyclable elastomeric components.

Advantages of Using Thermoplastic Rubber (TPR)

Thermoplastic Rubber (TPR) offers superior flexibility and resilience compared to Thermoplastic Elastomer (TPE), making it ideal for applications requiring durable and elastic materials. TPR exhibits enhanced abrasion resistance and excellent tactile properties, which improve product longevity and user comfort. Its recyclability and efficient processing also reduce manufacturing costs and environmental impact.

Benefits of Thermoplastic Elastomer (TPE) Materials

Thermoplastic Elastomer (TPE) materials offer superior flexibility, elasticity, and resistance to wear compared to Thermoplastic Rubber (TPR), making them ideal for dynamic applications requiring durability and comfort. TPEs provide excellent thermal stability and chemical resistance, enhancing product longevity in automotive, medical, and consumer goods industries. Their recyclability and ease of processing contribute to sustainable manufacturing practices while maintaining high-performance characteristics.

Manufacturing Processes for TPR and TPE

Thermoplastic Rubber (TPR) is typically manufactured through a blending process that combines rubber and plastic polymers, allowing it to be melted and reshaped multiple times using injection molding or extrusion techniques. Thermoplastic Elastomer (TPE) production involves the polymerization of styrenic block copolymers, olefin-based copolymers, or vulcanized rubber that can be processed via injection molding, blow molding, or extrusion. Both TPR and TPE manufacturing processes emphasize recyclability and efficiency, but TPE offers broader customization in mechanical properties due to its varied polymer compositions.

Sustainability and Environmental Impact: TPR vs TPE

Thermoplastic Rubber (TPR) and Thermoplastic Elastomer (TPE) differ significantly in sustainability, with TPE often favored for its recyclable properties and lower environmental footprint. TPE materials generally consume less energy during production and generate fewer emissions, contributing to reduced ecological impact compared to conventional TPR. Innovations in bio-based TPE formulations further enhance environmental benefits by incorporating renewable resources and promoting circular economy principles.

Choosing Between TPR and TPE for Your Product Manufacturing

Thermoplastic Rubber (TPR) offers excellent flexibility and durability, making it ideal for applications requiring high elasticity and impact resistance, such as footwear soles and grips. Thermoplastic Elastomer (TPE) provides a broader range of hardness and customization options, suitable for automotive parts, medical devices, and consumer goods needing both soft-touch and rigid components. Choosing between TPR and TPE depends on product requirements like flexibility, environmental resistance, and processing methods to optimize performance and cost-efficiency.

Thermoplastic Rubber (TPR) vs Thermoplastic Elastomer (TPE) Infographic

materialdif.com

materialdif.com