Hardness testing measures rubber's resistance to surface deformation, providing quick insights into material durability and wear resistance. Tensile testing evaluates rubber's strength and elongation by assessing its behavior under stretching forces, revealing elasticity and failure points. Both tests are essential for ensuring rubber meets performance standards in various applications.

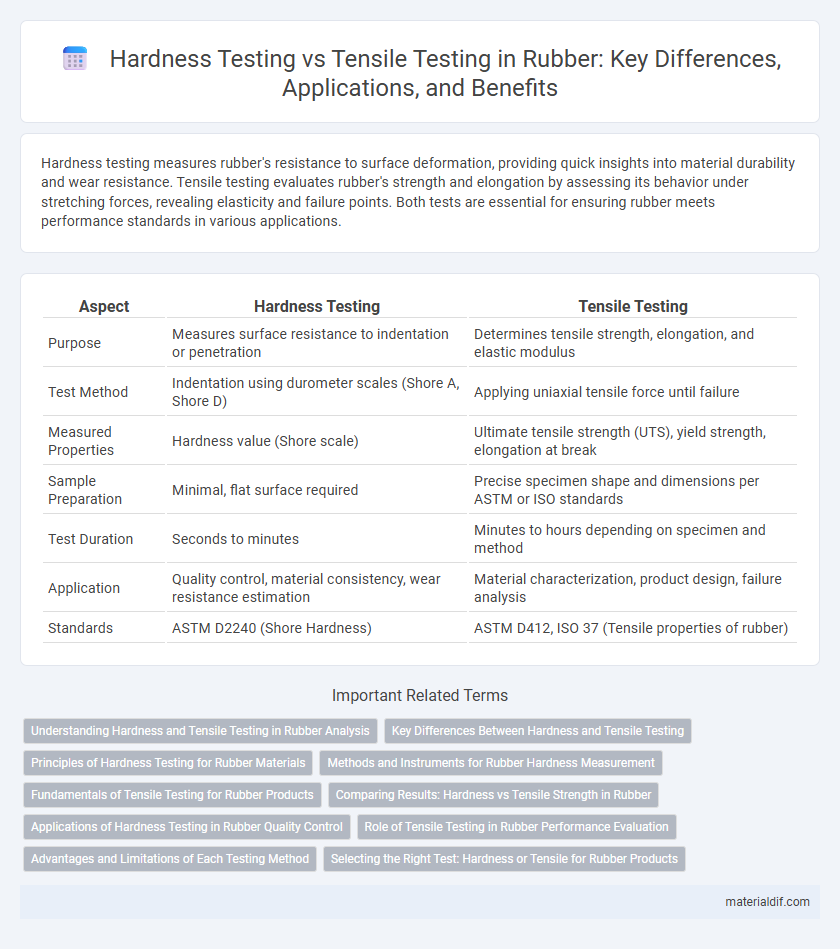

Table of Comparison

| Aspect | Hardness Testing | Tensile Testing |

|---|---|---|

| Purpose | Measures surface resistance to indentation or penetration | Determines tensile strength, elongation, and elastic modulus |

| Test Method | Indentation using durometer scales (Shore A, Shore D) | Applying uniaxial tensile force until failure |

| Measured Properties | Hardness value (Shore scale) | Ultimate tensile strength (UTS), yield strength, elongation at break |

| Sample Preparation | Minimal, flat surface required | Precise specimen shape and dimensions per ASTM or ISO standards |

| Test Duration | Seconds to minutes | Minutes to hours depending on specimen and method |

| Application | Quality control, material consistency, wear resistance estimation | Material characterization, product design, failure analysis |

| Standards | ASTM D2240 (Shore Hardness) | ASTM D412, ISO 37 (Tensile properties of rubber) |

Understanding Hardness and Tensile Testing in Rubber Analysis

Hardness testing in rubber analysis measures the material's resistance to surface indentation, providing critical data on durability and wear characteristics. Tensile testing evaluates rubber's strength and elasticity by recording the stress-strain behavior until failure, essential for understanding performance under mechanical stress. Combining both tests offers a comprehensive assessment of rubber's physical properties, ensuring optimized formulation and quality control in manufacturing processes.

Key Differences Between Hardness and Tensile Testing

Hardness testing measures a rubber material's resistance to indentation, providing quick and localized data on surface properties, while tensile testing evaluates the material's strength and elongation by stretching it until failure, offering comprehensive insights into elasticity and durability. Hardness tests use specific scales such as Shore A or Shore D, whereas tensile tests yield values like tensile strength, elongation at break, and modulus of elasticity. The choice between hardness and tensile testing depends on whether surface resistance or overall mechanical performance under stress is the critical parameter for rubber quality assessment.

Principles of Hardness Testing for Rubber Materials

Hardness testing for rubber materials measures resistance to surface indentation or penetration, typically using Shore or IRHD scales, which quantify material elasticity and deformation under applied force. This test evaluates the rubber's ability to resist permanent surface deformation, providing crucial information about its wear resistance and flexibility for specific applications. Unlike tensile testing, which assesses strength and elongation properties by pulling the sample, hardness testing offers quick, non-destructive insights into rubber's surface characteristics and suitability for sealing, cushioning, or vibration-damping components.

Methods and Instruments for Rubber Hardness Measurement

Rubber hardness testing primarily employs the Shore A and Shore D durometers, which measure the resistance of rubber surfaces to indentation using standardized scales; these handheld instruments provide quick and repeatable results essential for quality control. In contrast, tensile testing involves universal testing machines equipped with extensometers that apply controlled tension to rubber specimens, assessing their elongation, tensile strength, and modulus rather than surface hardness. Shore hardness testing is ideal for evaluating material stiffness, while tensile testing focuses on mechanical properties critical for durability and performance under stress.

Fundamentals of Tensile Testing for Rubber Products

Tensile testing for rubber products measures the material's ability to withstand stretching forces and assesses parameters like tensile strength, elongation at break, and modulus. This test provides critical data on the rubber's elasticity, durability, and overall performance under stress. Unlike hardness testing, which evaluates surface resistance to indentation, tensile testing reveals the fundamental mechanical properties essential for applications involving dynamic loads and deformation.

Comparing Results: Hardness vs Tensile Strength in Rubber

Hardness testing in rubber primarily measures resistance to surface deformation, providing quick insights into material durability but often correlates only indirectly with tensile strength. Tensile testing evaluates the material's ability to withstand pulling forces, directly measuring tensile strength and elongation at break, essential for assessing rubber's performance in applications involving stretch and stress. Comparing results reveals that while higher hardness values generally suggest increased tensile strength, variations in rubber formulations can lead to discrepancies, making both tests complementary for comprehensive rubber characterization.

Applications of Hardness Testing in Rubber Quality Control

Hardness testing in rubber quality control primarily assesses the material's resistance to indentation, ensuring consistent durability and flexibility for applications in automotive seals, gaskets, and footwear soles. This method provides rapid, non-destructive evaluation critical for maintaining product specifications and performance standards. Unlike tensile testing, hardness testing enables efficient detection of material inconsistencies and process variations during manufacturing.

Role of Tensile Testing in Rubber Performance Evaluation

Tensile testing plays a crucial role in evaluating rubber performance by measuring its ability to withstand forces that attempt to stretch it, providing key data on elasticity, tensile strength, and elongation at break. Unlike hardness testing, which assesses surface resistance to indentation, tensile testing offers comprehensive insights into the material's mechanical durability and flexibility under strain. This information is vital for applications requiring specific strength and deformation characteristics, such as automotive seals, hoses, and conveyor belts.

Advantages and Limitations of Each Testing Method

Hardness testing of rubber provides a quick and non-destructive measure of surface resistance, useful for quality control and batch consistency, but it does not fully capture the material's mechanical behavior under stress. Tensile testing offers detailed insights into the rubber's elasticity, strength, and elongation properties, making it essential for understanding performance in real-world applications, though it requires more time, sample preparation, and results in sample destruction. Combining both methods delivers a comprehensive assessment by balancing speed and surface hardness with in-depth mechanical characterization essential for product development and performance evaluation.

Selecting the Right Test: Hardness or Tensile for Rubber Products

Selecting the right test for rubber products depends on the specific performance criteria; hardness testing measures resistance to surface deformation and is ideal for applications requiring wear resistance assessment. Tensile testing evaluates the material's strength, elongation, and elasticity, crucial for understanding durability under mechanical stress. Choosing between hardness and tensile testing ensures accurate quality control and optimal product performance in rubber manufacturing.

Hardness Testing vs Tensile Testing Infographic

materialdif.com

materialdif.com