Thermoset rubber undergoes a chemical curing process that creates a permanent, cross-linked molecular structure, resulting in superior heat resistance, durability, and elasticity, making it ideal for heavy-duty applications. Thermoplastic rubber, on the other hand, can be melted and reshaped multiple times due to its linear polymer chains, offering easier processing, recyclability, and flexibility for lighter, less demanding uses. Understanding these differences helps manufacturers select the appropriate rubber type based on performance requirements and production methods.

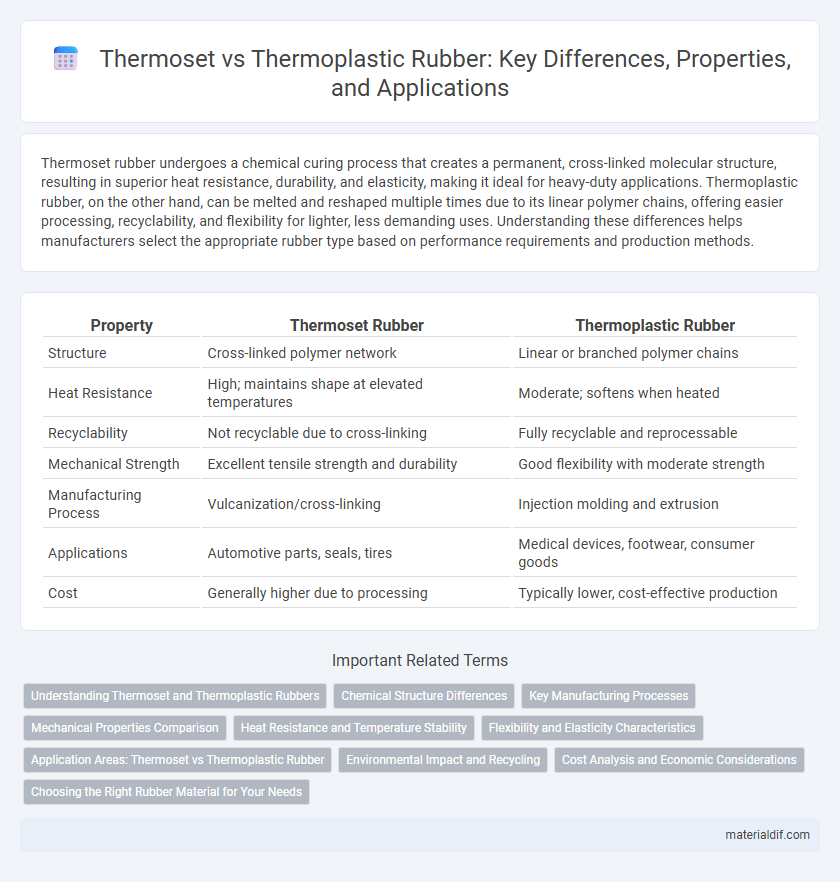

Table of Comparison

| Property | Thermoset Rubber | Thermoplastic Rubber |

|---|---|---|

| Structure | Cross-linked polymer network | Linear or branched polymer chains |

| Heat Resistance | High; maintains shape at elevated temperatures | Moderate; softens when heated |

| Recyclability | Not recyclable due to cross-linking | Fully recyclable and reprocessable |

| Mechanical Strength | Excellent tensile strength and durability | Good flexibility with moderate strength |

| Manufacturing Process | Vulcanization/cross-linking | Injection molding and extrusion |

| Applications | Automotive parts, seals, tires | Medical devices, footwear, consumer goods |

| Cost | Generally higher due to processing | Typically lower, cost-effective production |

Understanding Thermoset and Thermoplastic Rubbers

Thermoset rubber undergoes a chemical curing process that creates a cross-linked polymer structure, resulting in a material with high heat resistance, rigidity, and durability ideal for automotive and industrial seals. Thermoplastic rubber, by contrast, consists of linear or lightly branched polymers that soften when heated and harden upon cooling, offering excellent flexibility, ease of processing, and recyclability for applications like footwear and medical devices. Understanding these fundamental differences in molecular structure and thermal behavior is essential for selecting the right type of rubber for specific performance requirements.

Chemical Structure Differences

Thermoset rubber consists of cross-linked polymer chains forming a rigid, three-dimensional network that enhances heat resistance and durability but prevents reshaping. Thermoplastic rubber features linear or branched polymer chains without permanent cross-links, allowing it to soften upon heating and be molded multiple times. The chemical structure of thermoset rubber results from vulcanization, creating sulfur bridges, whereas thermoplastic rubber relies on physical mixing of polymers without chemical bonding between chains.

Key Manufacturing Processes

Thermoset rubber undergoes curing and vulcanization, creating a chemically cross-linked structure that enhances durability and heat resistance, commonly molded through compression or transfer molding. Thermoplastic rubber, shaped via processes such as injection molding or extrusion, relies on physical entanglements without chemical cross-linking, enabling easy melting and reshaping. The choice between these manufacturing techniques impacts product flexibility, recyclability, and application suitability in automotive, medical, and consumer goods industries.

Mechanical Properties Comparison

Thermoset rubber exhibits superior mechanical properties such as higher tensile strength, abrasion resistance, and elasticity retention compared to thermoplastic rubber, which generally offers greater flexibility and ease of processing. Thermoset materials maintain their shape under higher temperatures and stress due to their cross-linked molecular structure, whereas thermoplastic rubber softens and deforms when heated. The enhanced durability and chemical resistance of thermoset rubber make it ideal for heavy-duty applications, while thermoplastic rubber suits products requiring repeated molding and deformation.

Heat Resistance and Temperature Stability

Thermoset rubber exhibits superior heat resistance due to its chemically cross-linked molecular structure, maintaining stability at temperatures up to 250degC without deformation. In contrast, thermoplastic rubber softens when exposed to heat, typically becoming unstable above 150degC, which limits its application in high-temperature environments. The irreversible curing process of thermosets ensures consistent thermal performance, whereas thermoplastics offer recyclability but reduced temperature stability.

Flexibility and Elasticity Characteristics

Thermoset rubber exhibits superior elasticity due to its cross-linked polymer structure, which provides enhanced shape retention and resistance to deformation under stress. Thermoplastic rubber offers greater flexibility, allowing it to be reshaped and molded at higher temperatures without permanent set, though it typically has lower elasticity compared to thermoset variants. These differences impact their applications, with thermoset rubber preferred for durable, high-stress environments and thermoplastic rubber favored for adaptable, lightweight designs.

Application Areas: Thermoset vs Thermoplastic Rubber

Thermoset rubber is widely used in automotive parts, electrical insulators, and industrial seals due to its excellent heat resistance, rigidity, and durability under high stress. Thermoplastic rubber finds applications in flexible tubing, medical devices, and consumer electronics where reusability, ease of processing, and elasticity are essential. The choice between thermoset and thermoplastic rubber depends on specific performance requirements such as thermal stability, mechanical strength, and manufacturing flexibility.

Environmental Impact and Recycling

Thermoset rubber, known for its permanent cross-linked structure, is difficult to recycle and often ends up in landfills, contributing to environmental pollution. Thermoplastic rubber can be melted and reshaped multiple times, enabling more efficient recycling processes and reducing waste accumulation. The enhanced recyclability of thermoplastic rubber supports circular economy initiatives and lowers carbon footprint compared to thermoset alternatives.

Cost Analysis and Economic Considerations

Thermoplastic rubber typically offers lower production costs due to its recyclability and shorter cycle times, making it economically favorable for high-volume manufacturing. Thermoset rubber requires higher initial investment in molds and longer curing times, impacting upfront expenses but providing superior heat resistance and durability, which can reduce replacement costs in long-term applications. Evaluating lifecycle cost, thermoplastic rubber excels in cost efficiency for flexible, short-term use, while thermoset rubber proves more economical in durability-demanding environments.

Choosing the Right Rubber Material for Your Needs

Thermoset rubber offers superior heat resistance and chemical stability, making it ideal for high-temperature applications and long-term durability. Thermoplastic rubber provides excellent flexibility and recyclability, suitable for products requiring repeated molding and reshaping. Selecting the right rubber depends on performance requirements, environmental exposure, and manufacturing processes specific to your application.

Thermoset vs Thermoplastic Rubber Infographic

materialdif.com

materialdif.com