Abrasion resistance in rubber refers to the material's ability to withstand surface wear caused by friction or scraping, making it ideal for applications involving frequent contact with rough surfaces. Tear resistance measures how well rubber can resist propagation of cracks or tears under stress, crucial for maintaining structural integrity in dynamic or high-impact environments. Selecting rubber with the right balance between abrasion and tear resistance ensures durability and longevity in specific industrial uses.

Table of Comparison

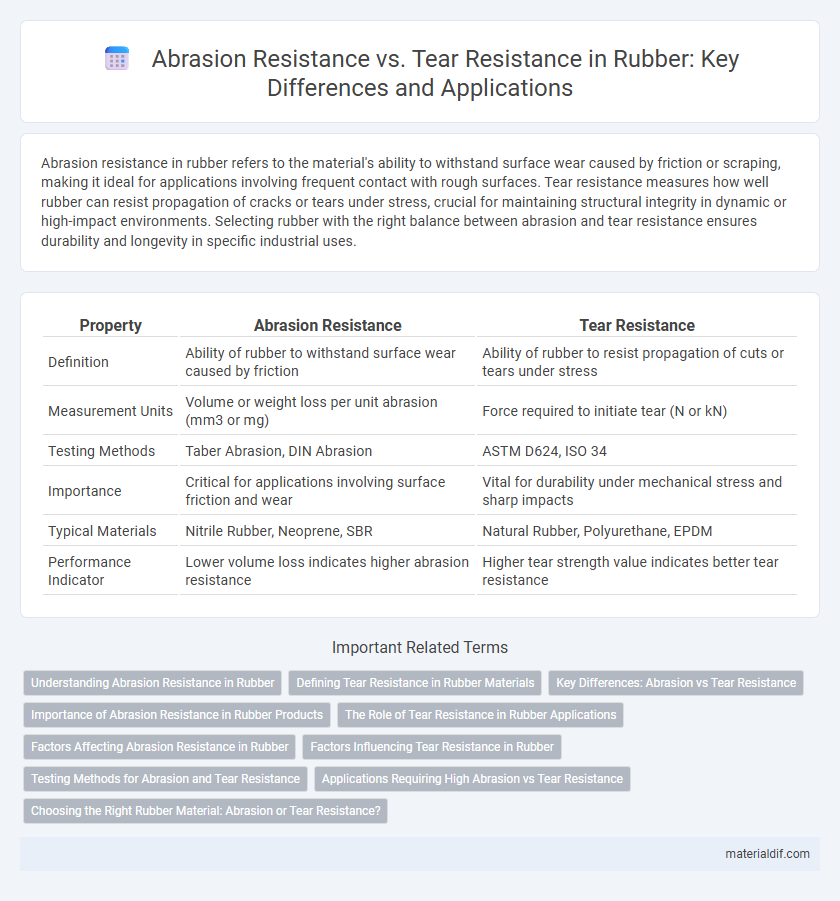

| Property | Abrasion Resistance | Tear Resistance |

|---|---|---|

| Definition | Ability of rubber to withstand surface wear caused by friction | Ability of rubber to resist propagation of cuts or tears under stress |

| Measurement Units | Volume or weight loss per unit abrasion (mm3 or mg) | Force required to initiate tear (N or kN) |

| Testing Methods | Taber Abrasion, DIN Abrasion | ASTM D624, ISO 34 |

| Importance | Critical for applications involving surface friction and wear | Vital for durability under mechanical stress and sharp impacts |

| Typical Materials | Nitrile Rubber, Neoprene, SBR | Natural Rubber, Polyurethane, EPDM |

| Performance Indicator | Lower volume loss indicates higher abrasion resistance | Higher tear strength value indicates better tear resistance |

Understanding Abrasion Resistance in Rubber

Abrasion resistance in rubber refers to the material's ability to withstand surface wear caused by friction or rubbing against other surfaces, which is critical for applications involving continuous contact with rough or abrasive environments. This property is influenced by the rubber's composition, including the type of polymer and fillers used, which enhance durability and longevity in products such as tires, conveyor belts, and seals. Understanding abrasion resistance helps in selecting the appropriate rubber formulation to ensure optimal performance and reduced maintenance costs in industrial and automotive applications.

Defining Tear Resistance in Rubber Materials

Tear resistance in rubber materials refers to the ability of the rubber to withstand the propagation of a crack or tear when subjected to stress or force. It is a critical property that determines the durability and lifespan of rubber products, especially in applications involving sharp edges or sudden impacts. High tear resistance ensures that rubber components can maintain their integrity and performance under harsh mechanical conditions.

Key Differences: Abrasion vs Tear Resistance

Abrasion resistance in rubber measures its ability to withstand surface wear caused by friction, while tear resistance evaluates the material's capacity to resist propagation of cuts or tears under stress. Key differences lie in the testing methods and mechanical properties assessed; abrasion resistance uses tests like the Taber abrasion test to simulate surface erosion, whereas tear resistance utilizes trouser or angle tear tests to determine force needed to extend a tear. Selecting rubber for applications requires understanding these differences, as high abrasion resistance suits environments with continuous rubbing, and high tear resistance is critical where sharp objects or sudden impacts are expected.

Importance of Abrasion Resistance in Rubber Products

Abrasion resistance in rubber products is crucial for extending service life by minimizing surface wear caused by friction, making it essential in applications like conveyor belts, tires, and seals. High abrasion resistance improves durability and performance under harsh conditions, significantly reducing maintenance costs and downtime. Compared to tear resistance, abrasion resistance directly impacts material longevity when exposed to continuous rubbing or scraping.

The Role of Tear Resistance in Rubber Applications

Tear resistance in rubber is a critical property that determines its durability and performance in applications subjected to sharp or sudden forces. Unlike abrasion resistance, which protects against surface wear, tear resistance prevents the propagation of cracks or cuts, ensuring structural integrity under mechanical stress. Industries such as automotive, aerospace, and heavy machinery prioritize high tear resistance in rubber components to enhance safety and extend service life.

Factors Affecting Abrasion Resistance in Rubber

Abrasion resistance in rubber is primarily influenced by the polymer composition, cross-link density, and filler types such as carbon black or silica, which enhance toughness and wear resistance. The hardness and elasticity of the rubber compound also determine its ability to withstand surface wear during frictional contact. Environmental conditions, including temperature and exposure to chemicals, further affect the durability and performance of abrasion-resistant rubber materials.

Factors Influencing Tear Resistance in Rubber

Tear resistance in rubber is primarily influenced by the polymer's molecular structure, crosslink density, and filler content such as carbon black or silica. Higher crosslink density enhances the rubber's ability to resist crack propagation, while filler dispersion improves stress distribution around tear points. Environmental factors like temperature and the presence of oils or chemicals also significantly affect tear resistance by altering the rubber's elasticity and strength.

Testing Methods for Abrasion and Tear Resistance

Abrasion resistance testing for rubber commonly utilizes the DIN Abrasion Method, where a standardized abrasive surface rubs against the rubber under controlled pressure to measure material loss. Tear resistance is typically evaluated using the ASTM D624 test, which involves applying a tensile force on a pre-cut specimen until it propagates a tear, quantifying the energy required for tear extension. Both testing methods provide critical data on rubber durability essential for industrial applications like conveyor belts and automotive components.

Applications Requiring High Abrasion vs Tear Resistance

Applications requiring high abrasion resistance in rubber, such as conveyor belts and industrial flooring, demand materials that withstand repeated surface wear and friction. In contrast, applications like gaskets and seals benefit from enhanced tear resistance to prevent material failure under sudden or sustained stress. Selecting rubber compounds with optimized abrasion or tear resistance ensures longevity and performance tailored to specific operational challenges.

Choosing the Right Rubber Material: Abrasion or Tear Resistance?

Selecting the appropriate rubber material requires evaluating application-specific demands for abrasion resistance versus tear resistance. Natural rubber excels in tear resistance due to its high tensile strength and elasticity, making it suitable for products exposed to punctures or cracks. For environments with intense friction and surface wear, nitrile rubber or neoprene provide superior abrasion resistance, extending the lifespan of components such as seals, gaskets, and conveyor belts.

Abrasion Resistance vs Tear Resistance Infographic

materialdif.com

materialdif.com