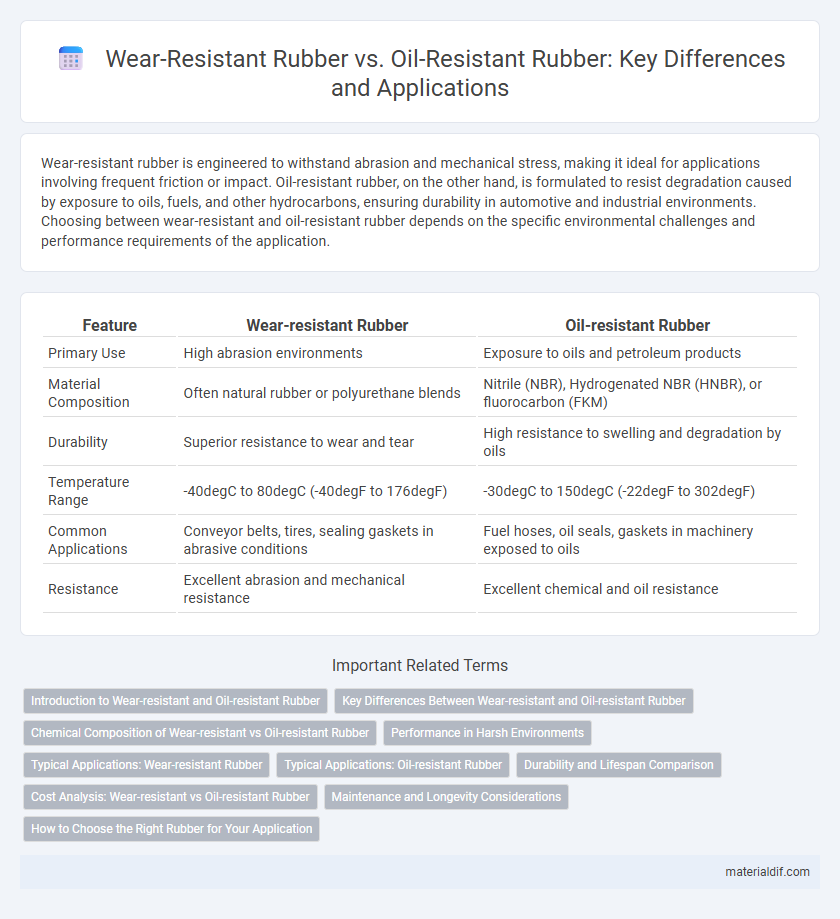

Wear-resistant rubber is engineered to withstand abrasion and mechanical stress, making it ideal for applications involving frequent friction or impact. Oil-resistant rubber, on the other hand, is formulated to resist degradation caused by exposure to oils, fuels, and other hydrocarbons, ensuring durability in automotive and industrial environments. Choosing between wear-resistant and oil-resistant rubber depends on the specific environmental challenges and performance requirements of the application.

Table of Comparison

| Feature | Wear-resistant Rubber | Oil-resistant Rubber |

|---|---|---|

| Primary Use | High abrasion environments | Exposure to oils and petroleum products |

| Material Composition | Often natural rubber or polyurethane blends | Nitrile (NBR), Hydrogenated NBR (HNBR), or fluorocarbon (FKM) |

| Durability | Superior resistance to wear and tear | High resistance to swelling and degradation by oils |

| Temperature Range | -40degC to 80degC (-40degF to 176degF) | -30degC to 150degC (-22degF to 302degF) |

| Common Applications | Conveyor belts, tires, sealing gaskets in abrasive conditions | Fuel hoses, oil seals, gaskets in machinery exposed to oils |

| Resistance | Excellent abrasion and mechanical resistance | Excellent chemical and oil resistance |

Introduction to Wear-resistant and Oil-resistant Rubber

Wear-resistant rubber is engineered to withstand abrasion, cuts, and mechanical wear, making it ideal for industrial applications such as conveyor belts, tires, and seals exposed to friction and rough surfaces. Oil-resistant rubber, typically formulated with nitrile or fluorocarbon polymers, resists degradation and swelling caused by oils, fuels, and chemicals, ensuring durability in automotive, aerospace, and manufacturing environments. Both types of rubber enhance product lifespan by providing specialized protection tailored to demanding operational conditions.

Key Differences Between Wear-resistant and Oil-resistant Rubber

Wear-resistant rubber is engineered for high abrasion resistance, making it ideal for applications involving constant friction and mechanical wear, whereas oil-resistant rubber is formulated to withstand exposure to petroleum-based oils and chemicals without degrading. Wear-resistant rubber typically features compounds like natural rubber or polyurethane, optimized for toughness and durability, while oil-resistant variants often use nitrile, fluorocarbon, or silicone polymers to maintain elasticity and integrity in oily environments. The key difference lies in their chemical compositions and performance properties, tailored to either mechanical durability or chemical resistance depending on the industrial application.

Chemical Composition of Wear-resistant vs Oil-resistant Rubber

Wear-resistant rubber typically contains high levels of natural or synthetic polymers like styrene-butadiene rubber (SBR) combined with reinforcing fillers such as carbon black and silica to enhance abrasion resistance. Oil-resistant rubber often incorporates nitrile butadiene rubber (NBR) or hydrogenated nitrile butadiene rubber (HNBR) due to their polar nitrile groups, which provide excellent resistance to oils, fuels, and chemicals. The key chemical difference lies in the functional groups and polymer backbone structures that define their respective resistance properties: wear resistance through cross-linked networks and filler dispersion, and oil resistance through polar interactions that prevent swelling and degradation.

Performance in Harsh Environments

Wear-resistant rubber exhibits superior durability and abrasion resistance, making it ideal for applications involving heavy mechanical stresses and rough surfaces. Oil-resistant rubber maintains integrity and elasticity when exposed to petroleum products, preventing degradation and swelling in oily or chemical-rich environments. In harsh environments combining mechanical wear and oil exposure, specialized blends or layered materials enhance overall performance by balancing both wear resistance and oil resistance.

Typical Applications: Wear-resistant Rubber

Wear-resistant rubber is commonly used in applications requiring high durability against abrasion, such as conveyor belts, mining machinery liners, and truck bed liners. Its robust composition makes it ideal for heavy-duty environments like industrial floors and chutes exposed to constant friction. These properties ensure extended service life and reduced maintenance costs in sectors including construction, mining, and material handling.

Typical Applications: Oil-resistant Rubber

Oil-resistant rubber is widely used in automotive seals, gaskets, and hoses exposed to fuel and lubricants, ensuring durability against hydrocarbon degradation. It is common in industrial conveyor belts and oil-resistant gloves for handling chemicals and oils safely. This material is crucial in manufacturing oil seals and O-rings that maintain mechanical integrity in harsh, oily environments.

Durability and Lifespan Comparison

Wear-resistant rubber is engineered to endure heavy abrasion and mechanical stress, significantly enhancing durability and extending lifespan in high-friction environments. Oil-resistant rubber, formulated with specialized polymers like nitrile or fluorocarbon, resists chemical degradation from oils and fuels, preserving integrity and function over prolonged exposure. Comparing both, wear-resistant rubber excels in mechanical longevity, while oil-resistant rubber maintains durability under chemical attack, making material choice critical based on operational conditions and expected wear factors.

Cost Analysis: Wear-resistant vs Oil-resistant Rubber

Wear-resistant rubber typically incurs lower initial costs due to its simpler compound formulation and widespread availability, making it cost-effective for applications prioritizing durability against abrasion. Oil-resistant rubber requires specialized additives and polymers to withstand hydrocarbon exposure, resulting in higher production and material expenses, which increase upfront investment. Over time, oil-resistant rubber's extended lifespan in oily environments can offset its higher cost by reducing replacement frequency and maintenance expenses.

Maintenance and Longevity Considerations

Wear-resistant rubber offers superior durability under abrasive conditions, significantly reducing maintenance frequency and extending service life in industrial applications. Oil-resistant rubber provides enhanced chemical stability, protecting against degradation from hydrocarbons, but may require more frequent inspections to prevent unforeseen wear in dynamic environments. Selecting the appropriate compound based on exposure conditions ensures optimal longevity and cost-effective maintenance strategies.

How to Choose the Right Rubber for Your Application

Selecting the right rubber depends on the environmental conditions and mechanical stresses involved in your application. Wear-resistant rubber excels in scenarios requiring high abrasion resistance, such as conveyor belts and industrial seals, while oil-resistant rubber is ideal for contact with hydrocarbons, fuels, and lubricants to maintain elasticity and prevent swelling. Evaluating factors like temperature range, chemical exposure, and physical wear helps determine the optimal rubber type for durability and performance.

Wear-resistant Rubber vs Oil-resistant Rubber Infographic

materialdif.com

materialdif.com