Solid rubber offers superior durability and resistance to abrasion, making it ideal for heavy-duty applications where strength and longevity are crucial. Foam rubber provides excellent cushioning and flexibility, enhancing comfort and shock absorption in products like mattresses and padding. Choosing between solid and foam rubber depends on the specific requirements for toughness versus softness in various industrial and consumer uses.

Table of Comparison

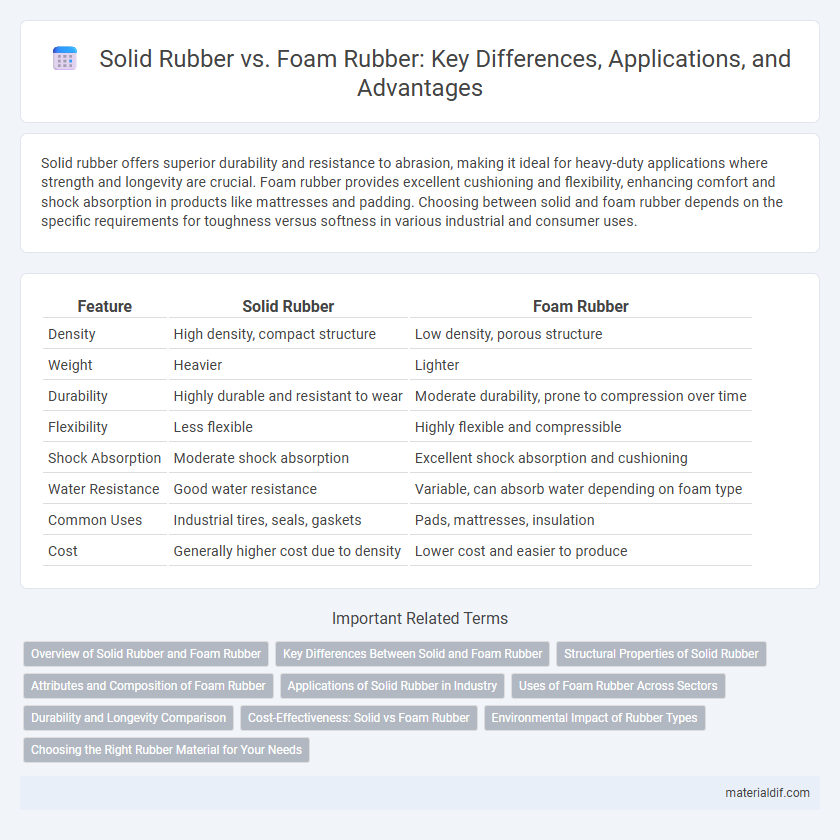

| Feature | Solid Rubber | Foam Rubber |

|---|---|---|

| Density | High density, compact structure | Low density, porous structure |

| Weight | Heavier | Lighter |

| Durability | Highly durable and resistant to wear | Moderate durability, prone to compression over time |

| Flexibility | Less flexible | Highly flexible and compressible |

| Shock Absorption | Moderate shock absorption | Excellent shock absorption and cushioning |

| Water Resistance | Good water resistance | Variable, can absorb water depending on foam type |

| Common Uses | Industrial tires, seals, gaskets | Pads, mattresses, insulation |

| Cost | Generally higher cost due to density | Lower cost and easier to produce |

Overview of Solid Rubber and Foam Rubber

Solid rubber offers high durability, excellent resistance to wear and tear, and superior load-bearing capacity, making it ideal for heavy-duty applications. Foam rubber, characterized by its lightweight and cushioning properties, provides superior shock absorption and flexibility, commonly used in padding and insulation. Both materials serve distinct purposes based on their unique structural and mechanical properties in industries ranging from automotive to consumer goods.

Key Differences Between Solid and Foam Rubber

Solid rubber offers higher density and durability, making it ideal for heavy-duty applications requiring strong impact resistance and abrasion. Foam rubber is lightweight and porous, providing superior cushioning, flexibility, and sound absorption, which suits comfort-focused uses like mattresses and insoles. The fundamental difference lies in the material structure: solid rubber is a continuous mass, while foam rubber contains air pockets that reduce weight and enhance elasticity.

Structural Properties of Solid Rubber

Solid rubber exhibits superior structural properties compared to foam rubber, characterized by high density, greater tensile strength, and excellent resistance to wear and tear. Its compact molecular structure provides enhanced durability and load-bearing capacity, making it ideal for applications requiring robust mechanical performance. Additionally, solid rubber's impermeability and resistance to deformation under stress contribute to its reliability in industrial uses such as seals, gaskets, and tires.

Attributes and Composition of Foam Rubber

Foam rubber consists of a cellular structure created by incorporating gas bubbles into a rubber matrix, resulting in a lightweight, flexible material with enhanced cushioning and shock absorption properties. Unlike solid rubber, foam rubber typically has lower density and greater compressibility, making it ideal for applications requiring vibration dampening and comfort, such as mattresses, upholstery, and insulation. The composition often includes natural or synthetic rubber combined with blowing agents that create the foam's unique porous texture and resilience.

Applications of Solid Rubber in Industry

Solid rubber is extensively used in industrial applications requiring durability and resistance to wear, such as conveyor belts, seals, gaskets, and vibration dampening components. Its high tensile strength and abrasion resistance make it ideal for heavy machinery parts and automotive tires. Solid rubber also serves critical roles in manufacturing environments where chemical resistance and load-bearing capacity are essential.

Uses of Foam Rubber Across Sectors

Foam rubber's lightweight, cushioning properties make it ideal for automotive seats, soundproofing panels, and insulation in construction. In healthcare, foam rubber is used for orthopedic supports, mattresses, and prosthetics to enhance comfort and pressure relief. Its versatility extends to packaging materials and sports equipment padding, providing impact absorption and durability across multiple industries.

Durability and Longevity Comparison

Solid rubber offers superior durability and longevity compared to foam rubber due to its dense composition and resistance to wear, abrasion, and environmental factors. Foam rubber, although lightweight and flexible, tends to degrade faster under continuous pressure, exposure to UV light, and moisture. Industries requiring long-term performance, such as automotive and heavy machinery, often prefer solid rubber for its ability to maintain structural integrity over extended periods.

Cost-Effectiveness: Solid vs Foam Rubber

Solid rubber typically offers higher durability and longer lifespan, making it more cost-effective for heavy-duty applications despite a higher upfront price. Foam rubber provides cushioning and lightweight properties at a lower initial cost but may require more frequent replacement due to reduced durability. Choosing between solid and foam rubber depends on balancing upfront investment with maintenance and replacement expenses.

Environmental Impact of Rubber Types

Solid rubber generally has a lower environmental impact compared to foam rubber due to its longer durability and recyclability, reducing waste generation. Foam rubber production often involves petrochemical foaming agents that release volatile organic compounds (VOCs), contributing to air pollution and greenhouse gas emissions. Proper disposal and recycling methods for solid rubber reduce landfill burden, whereas foam rubber, being less dense and more difficult to recycle, frequently ends up in landfills, exacerbating environmental harm.

Choosing the Right Rubber Material for Your Needs

Solid rubber offers superior durability, high tensile strength, and excellent resistance to abrasion, making it ideal for heavy-duty applications such as industrial seals and tires. Foam rubber provides lightweight cushioning, enhanced shock absorption, and flexibility, suitable for padding, insulation, and comfort-focused uses. Selecting the right rubber material depends on the specific requirements for strength, resilience, and cushioning in your project or product design.

Solid Rubber vs Foam Rubber Infographic

materialdif.com

materialdif.com