Latex harvesting involves extracting natural rubber from the sap of rubber trees, which offers a renewable and biodegradable source of rubber. Polymerization, on the other hand, is a synthetic process that produces rubber by chemically combining monomers, resulting in materials with tailored properties for industrial use. Natural latex provides elasticity and resilience, while polymerized rubber allows for enhanced durability and resistance in various applications.

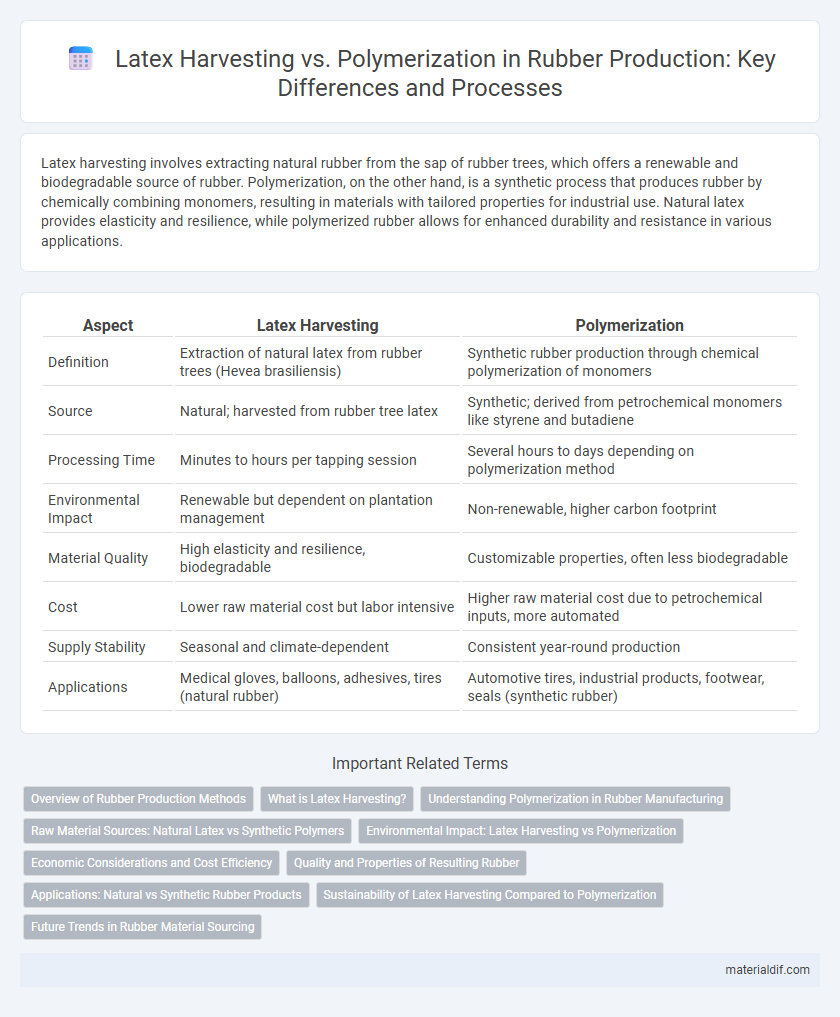

Table of Comparison

| Aspect | Latex Harvesting | Polymerization |

|---|---|---|

| Definition | Extraction of natural latex from rubber trees (Hevea brasiliensis) | Synthetic rubber production through chemical polymerization of monomers |

| Source | Natural; harvested from rubber tree latex | Synthetic; derived from petrochemical monomers like styrene and butadiene |

| Processing Time | Minutes to hours per tapping session | Several hours to days depending on polymerization method |

| Environmental Impact | Renewable but dependent on plantation management | Non-renewable, higher carbon footprint |

| Material Quality | High elasticity and resilience, biodegradable | Customizable properties, often less biodegradable |

| Cost | Lower raw material cost but labor intensive | Higher raw material cost due to petrochemical inputs, more automated |

| Supply Stability | Seasonal and climate-dependent | Consistent year-round production |

| Applications | Medical gloves, balloons, adhesives, tires (natural rubber) | Automotive tires, industrial products, footwear, seals (synthetic rubber) |

Overview of Rubber Production Methods

Latex harvesting involves collecting natural rubber sap from Hevea brasiliensis trees through tapping, providing raw material that is processed into various natural rubber products. Polymerization refers to synthesizing synthetic rubber by chemically bonding monomers like styrene and butadiene, enabling controlled properties and large-scale production. Both methods are essential for meeting global rubber demand, with natural latex prized for elasticity and synthetic rubber valued for durability and resistance.

What is Latex Harvesting?

Latex harvesting involves collecting the natural sap from rubber trees by making precise incisions on the bark, allowing the latex to flow out and be gathered without harming the tree. This method preserves the tree's health and enables sustainable rubber production, supplying raw material for various industries. Latex is the foundational organic compound used in producing natural rubber before it undergoes polymerization for manufacturing finished goods.

Understanding Polymerization in Rubber Manufacturing

Polymerization in rubber manufacturing involves linking monomers, such as isoprene, into long polymer chains to create synthetic rubber with controlled properties. Unlike latex harvesting, which extracts natural rubber directly from Hevea brasiliensis trees, polymerization allows for customization of rubber characteristics to meet specific industrial needs. This chemical process ensures consistent quality and performance in products ranging from tires to medical devices.

Raw Material Sources: Natural Latex vs Synthetic Polymers

Natural latex is harvested directly from rubber trees (Hevea brasiliensis) through a tapping process, producing a renewable raw material rich in cis-1,4-polyisoprene. Synthetic polymers used in polymerization, such as styrene-butadiene rubber and polyisoprene, are derived from petrochemical feedstocks like butadiene and styrene monomers, offering controlled molecular structures and properties. The choice between natural latex and synthetic polymers impacts raw material sustainability, elasticity, and resistance characteristics in rubber production.

Environmental Impact: Latex Harvesting vs Polymerization

Latex harvesting from rubber trees is a sustainable process that promotes carbon sequestration and maintains biodiversity by preserving forest ecosystems. Polymerization, the chemical synthesis of synthetic rubber, relies heavily on petrochemical resources, resulting in higher greenhouse gas emissions and fossil fuel depletion. The environmental footprint of natural latex harvesting is significantly lower compared to synthetic rubber production through polymerization, making it a greener choice for rubber manufacturing.

Economic Considerations and Cost Efficiency

Latex harvesting involves tapping rubber trees to extract natural latex, yielding a renewable raw material with lower initial production costs but higher labor expenses and seasonal variability. Polymerization of synthetic rubber offers consistent quality and scalability with higher capital investment but reduced dependency on climatic conditions. Economic considerations favor latex harvesting in regions with abundant rubber plantations, while polymerization provides cost efficiency for large-scale industrial production where stable supply and uniformity are critical.

Quality and Properties of Resulting Rubber

Latex harvesting produces natural rubber with high elasticity, tensile strength, and superior resilience due to its preserved molecular structure. Polymerization, used to create synthetic rubber, offers tailored properties such as enhanced chemical resistance and controlled hardness, but may lack the natural rubber's flexibility. The choice between latex harvesting and polymerization directly impacts the rubber's performance, durability, and application suitability.

Applications: Natural vs Synthetic Rubber Products

Natural rubber derived from latex harvesting offers superior elasticity and resilience, making it ideal for products like tires, medical gloves, and adhesives. Synthetic rubber produced through polymerization provides enhanced chemical resistance and durability, suited for automotive seals, industrial gaskets, and synthetic footwear. The choice between natural and synthetic rubber hinges on application-specific requirements such as flexibility, environmental resistance, and cost-effectiveness.

Sustainability of Latex Harvesting Compared to Polymerization

Latex harvesting from Hevea brasiliensis trees offers a sustainable approach by maintaining the natural growth cycle and reducing environmental degradation compared to synthetic rubber produced through energy-intensive polymerization processes. The eco-friendly practice of tapping preserves forest biodiversity and requires less fossil fuel consumption, significantly lowering the carbon footprint associated with rubber production. Sustainable latex harvesting supports rural economies and promotes circularity by enabling biodegradable natural rubber products, contrasting with the non-renewable input and waste challenges of polymer-based rubber.

Future Trends in Rubber Material Sourcing

Latex harvesting involves natural extraction of rubber from Hevea brasiliensis trees, ensuring sustainability and biodegradability, while polymerization synthesizes rubber from petrochemical sources, offering material consistency and performance customization. Future trends emphasize integrating bio-based polymers and advanced polymerization techniques to reduce environmental impact and enhance material properties. Innovations in green chemistry and automation are driving a shift towards hybrid sourcing models combining natural latex and synthetic polymers for superior rubber production.

Latex Harvesting vs Polymerization Infographic

materialdif.com

materialdif.com