Rubber injection molding offers precise control and faster production cycles by injecting molten rubber into a mold, making it ideal for complex and high-volume parts. In contrast, rubber compression molding involves placing pre-measured rubber into a heated mold cavity and applying pressure, which suits simpler designs and smaller production runs. Choosing between these methods depends on factors like part complexity, production volume, and cost efficiency.

Table of Comparison

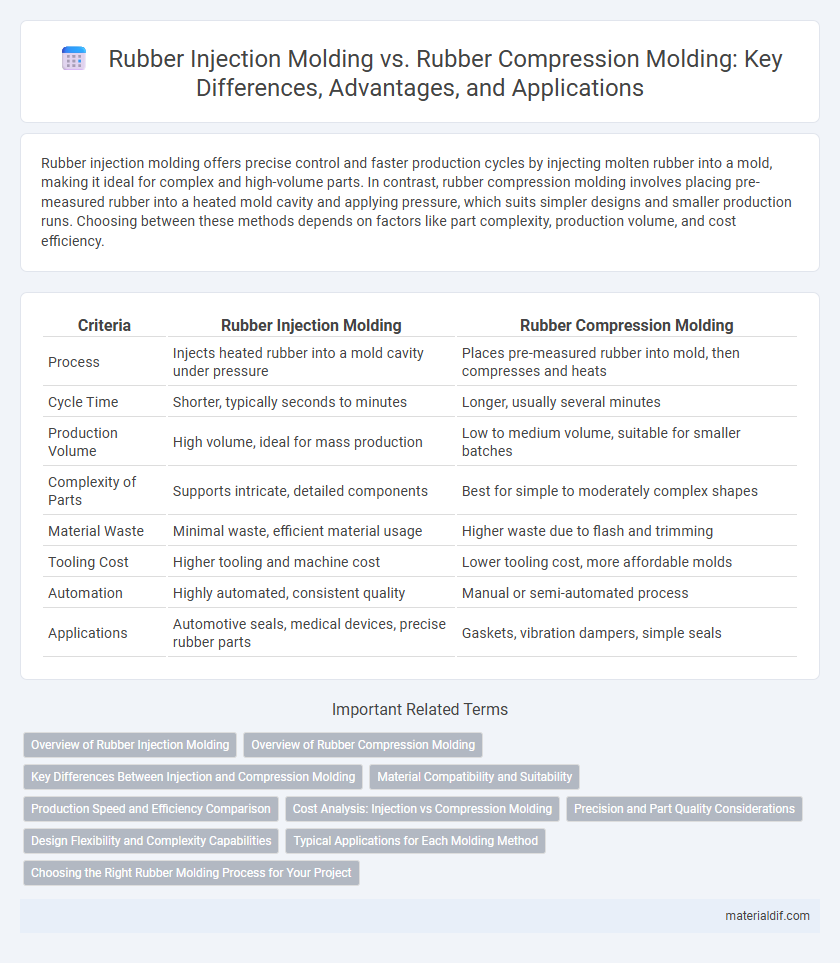

| Criteria | Rubber Injection Molding | Rubber Compression Molding |

|---|---|---|

| Process | Injects heated rubber into a mold cavity under pressure | Places pre-measured rubber into mold, then compresses and heats |

| Cycle Time | Shorter, typically seconds to minutes | Longer, usually several minutes |

| Production Volume | High volume, ideal for mass production | Low to medium volume, suitable for smaller batches |

| Complexity of Parts | Supports intricate, detailed components | Best for simple to moderately complex shapes |

| Material Waste | Minimal waste, efficient material usage | Higher waste due to flash and trimming |

| Tooling Cost | Higher tooling and machine cost | Lower tooling cost, more affordable molds |

| Automation | Highly automated, consistent quality | Manual or semi-automated process |

| Applications | Automotive seals, medical devices, precise rubber parts | Gaskets, vibration dampers, simple seals |

Overview of Rubber Injection Molding

Rubber injection molding involves injecting heated rubber material into a mold cavity under high pressure, enabling precise shaping and faster production cycles compared to compression molding. This method is ideal for complex designs with tight tolerances and offers superior repeatability and automation potential. Industries such as automotive and medical rely on rubber injection molding for high-volume manufacturing of durable rubber components.

Overview of Rubber Compression Molding

Rubber compression molding involves placing pre-measured rubber compounds into a heated mold cavity, where pressure and heat force the material to conform to the mold's shape, making it ideal for producing large, simple, or thick parts with excellent strength and durability. This method offers lower tooling costs and is efficient for low to medium production volumes compared to rubber injection molding, which requires more complex machinery and higher initial investment. Compression molding's ability to handle a wide range of rubber compounds and produce consistent, high-quality parts makes it a preferred choice in automotive, aerospace, and industrial applications.

Key Differences Between Injection and Compression Molding

Rubber injection molding involves injecting heated rubber into a mold under high pressure, allowing for precise, fast production of complex shapes with tight tolerances, ideal for high-volume manufacturing. Compression molding, on the other hand, places pre-measured rubber into an open mold, which is then closed and heated to cure the material, better suited for larger parts and lower production runs with simpler geometries. Key differences include cycle time, cost efficiency, material waste, and part consistency, with injection molding offering shorter cycle times and higher precision compared to the more labor-intensive compression molding process.

Material Compatibility and Suitability

Rubber injection molding offers superior material compatibility for complex, high-precision parts using a wide range of elastomers such as silicone, EPDM, and nitrile, making it ideal for high-volume production with consistent quality. Rubber compression molding suits materials that require high heat and pressure to cure, like natural rubber and neoprene, and is better for larger, thicker components with simpler geometries. Selecting the appropriate method depends on the elastomer's flow characteristics, curing requirements, and the part's design complexity to ensure optimal performance and durability.

Production Speed and Efficiency Comparison

Rubber injection molding offers faster production cycles compared to rubber compression molding, with cycle times often reduced by up to 50%, significantly enhancing manufacturing efficiency. Injection molding allows automated processes that minimize manual intervention, leading to consistent part quality and higher throughput. In contrast, compression molding involves longer curing times and labor-intensive steps, making it less efficient for high-volume production runs.

Cost Analysis: Injection vs Compression Molding

Rubber injection molding generally incurs higher initial equipment costs but offers lower per-unit costs for large production runs due to faster cycle times and automation. Compression molding features lower upfront tool expenses, making it more cost-effective for small to medium batch sizes or simpler part designs. Evaluating total cost involves balancing tooling investment against production volume and complexity to determine the most economical rubber molding method.

Precision and Part Quality Considerations

Rubber injection molding offers superior precision with consistent part dimensions due to automated material injection and controlled temperature settings, reducing defects such as flash and voids. Compression molding, while cost-effective for low-volume runs, often results in less uniformity and higher variability in part quality because manual handling and pressure application can introduce inconsistencies. For applications demanding tight tolerances and high repeatability, injection molding is the preferred method to ensure optimal rubber part quality.

Design Flexibility and Complexity Capabilities

Rubber injection molding offers superior design flexibility with the ability to produce intricate and complex geometries due to precise control over material flow and mold pressure. In contrast, rubber compression molding is better suited for simpler designs and larger parts as it relies on molding pre-measured amounts of rubber under heat and pressure. Injection molding supports high-precision components with tight tolerances, making it ideal for intricate, high-volume production.

Typical Applications for Each Molding Method

Rubber injection molding is ideal for producing high-volume, precision parts such as seals, gaskets, and O-rings commonly used in automotive and medical industries due to its fast cycle times and consistent quality. Rubber compression molding suits low to medium volume production of larger, simpler rubber components like tires, hoses, and vibration dampers, offering cost-effective tooling and material versatility. Both methods serve distinct manufacturing needs, with injection molding excelling in detailed designs and compression molding preferred for robust, bulkier parts.

Choosing the Right Rubber Molding Process for Your Project

Selecting the right rubber molding process depends on factors such as production volume, part complexity, and material type. Rubber injection molding offers faster cycle times and greater precision, making it ideal for high-volume, intricate designs. Rubber compression molding suits lower volumes and larger parts, providing cost-effective production with good mechanical properties.

Rubber Injection Molding vs Rubber Compression Molding Infographic

materialdif.com

materialdif.com