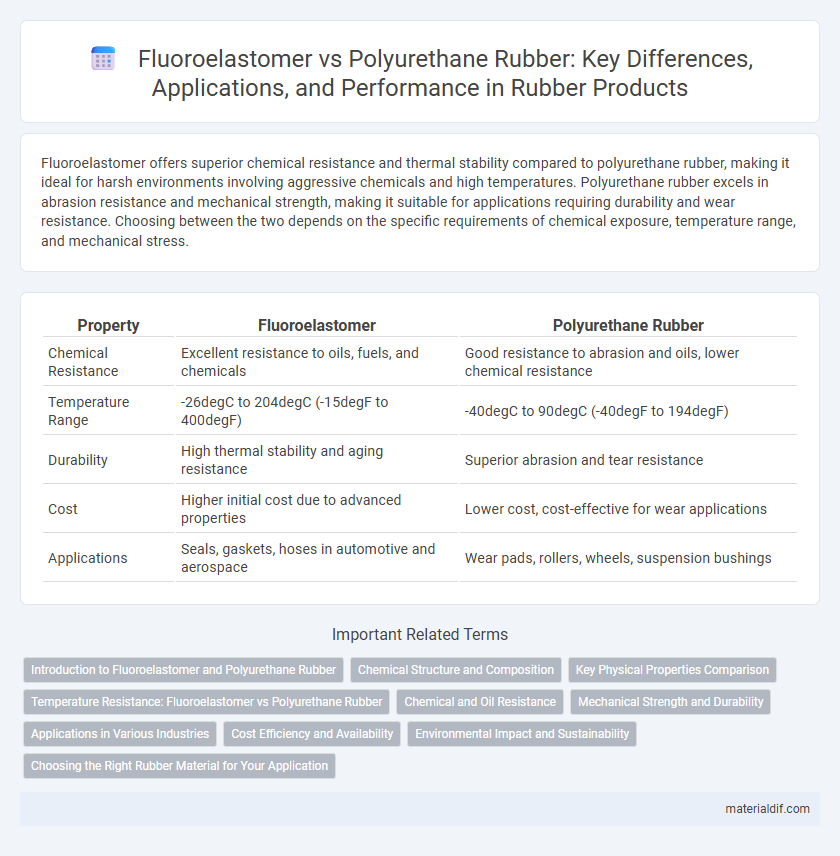

Fluoroelastomer offers superior chemical resistance and thermal stability compared to polyurethane rubber, making it ideal for harsh environments involving aggressive chemicals and high temperatures. Polyurethane rubber excels in abrasion resistance and mechanical strength, making it suitable for applications requiring durability and wear resistance. Choosing between the two depends on the specific requirements of chemical exposure, temperature range, and mechanical stress.

Table of Comparison

| Property | Fluoroelastomer | Polyurethane Rubber |

|---|---|---|

| Chemical Resistance | Excellent resistance to oils, fuels, and chemicals | Good resistance to abrasion and oils, lower chemical resistance |

| Temperature Range | -26degC to 204degC (-15degF to 400degF) | -40degC to 90degC (-40degF to 194degF) |

| Durability | High thermal stability and aging resistance | Superior abrasion and tear resistance |

| Cost | Higher initial cost due to advanced properties | Lower cost, cost-effective for wear applications |

| Applications | Seals, gaskets, hoses in automotive and aerospace | Wear pads, rollers, wheels, suspension bushings |

Introduction to Fluoroelastomer and Polyurethane Rubber

Fluoroelastomer is a high-performance synthetic rubber known for its exceptional resistance to heat, chemicals, and oil, making it ideal for demanding industrial applications. Polyurethane rubber offers superior abrasion resistance and mechanical strength, commonly used in heavy-duty environments requiring durability and elasticity. Both materials serve critical roles in sealing, automotive, and aerospace industries, with fluoroelastomers excelling in harsh chemical exposure and polyurethanes providing enhanced wear resistance.

Chemical Structure and Composition

Fluoroelastomers consist of fluorine-containing polymers that provide exceptional chemical resistance and thermal stability due to strong carbon-fluorine bonds. Polyurethane rubber is composed of segmented polymers with hard and soft segments derived from isocyanates and polyols, offering superior abrasion resistance and flexibility. The distinct chemical structures lead fluoroelastomers to excel in harsh chemical environments, while polyurethane rubber is preferred for applications requiring toughness and elasticity.

Key Physical Properties Comparison

Fluoroelastomer exhibits superior chemical resistance, thermal stability up to 250degC, and excellent barrier properties compared to polyurethane rubber, which typically offers higher abrasion resistance and tensile strength but lower heat and chemical tolerance. Polyurethane rubber performs well under dynamic stress with flexibility and resilience but degrades faster in harsh chemical environments where fluoroelastomer remains stable. The choice between these elastomers depends on application requirements such as temperature exposure, chemical contact, and mechanical wear.

Temperature Resistance: Fluoroelastomer vs Polyurethane Rubber

Fluoroelastomer exhibits superior temperature resistance, maintaining stability and performance in extreme conditions ranging from -40degC to 200degC, unlike polyurethane rubber which typically withstands temperatures only between -40degC and 90degC. This high thermal tolerance makes fluoroelastomer ideal for applications involving harsh chemical exposure and prolonged heat exposure. Polyurethane rubber, while durable and abrasion-resistant, degrades faster under elevated temperatures, limiting its use in high heat environments.

Chemical and Oil Resistance

Fluoroelastomer excels in chemical and oil resistance due to its fluorine content, providing superior performance against aggressive fuels, oils, and solvents, and maintaining stability at high temperatures. Polyurethane rubber offers excellent abrasion resistance but has limited chemical resistance, especially to oils and hydrocarbons, which can cause swelling or degradation over time. Choosing fluoroelastomer ensures enhanced durability in harsh chemical environments, while polyurethane is better suited for mechanical wear applications with less chemical exposure.

Mechanical Strength and Durability

Fluoroelastomer exhibits superior mechanical strength and exceptional chemical resistance, making it highly durable in harsh environments with temperatures ranging from -20degC to 200degC. Polyurethane rubber offers excellent abrasion resistance and tensile strength, contributing to its durability in mechanical applications involving high wear and tear. While fluoroelastomers excel in chemical durability and heat resistance, polyurethanes outperform in elasticity and resilience under physical stress.

Applications in Various Industries

Fluoroelastomer excels in high-temperature and chemical-resistant applications, making it ideal for the automotive, aerospace, and chemical processing industries where durability against fuels and solvents is critical. Polyurethane rubber offers superior abrasion resistance and flexibility, commonly used in industrial rollers, seals, and conveyor belts across manufacturing, mining, and material handling sectors. Both elastomers serve specialized roles, with fluoroelastomers favored for extreme conditions and polyurethanes preferred for wear-intensive environments.

Cost Efficiency and Availability

Fluoroelastomer offers superior chemical resistance and high-temperature stability but comes at a significantly higher cost compared to polyurethane rubber, making it less cost-efficient for budget-sensitive applications. Polyurethane rubber is widely available and more affordable, providing excellent abrasion resistance and flexibility, which supports broader market accessibility and lower production expenses. This cost and availability dynamic often guides manufacturers to choose polyurethane rubber for general use while reserving fluoroelastomer for specialized, high-performance needs.

Environmental Impact and Sustainability

Fluoroelastomers exhibit high chemical resistance and durability, but their production involves fluorinated compounds that pose challenges for environmental degradation and recycling processes. Polyurethane rubber offers better biodegradability and can be synthesized with bio-based polyols, enhancing its sustainability profile and reducing dependence on fossil fuels. Both materials present trade-offs; fluoroelastomers excel in lifespan and chemical stability, while polyurethanes are more environmentally friendly throughout their lifecycle.

Choosing the Right Rubber Material for Your Application

Fluoroelastomer offers superior chemical resistance, high-temperature stability up to 200degC, and excellent durability in harsh environments, making it ideal for automotive seals and aerospace applications. Polyurethane rubber provides exceptional abrasion resistance, flexibility, and mechanical strength, suited for industrial rollers, wheels, and flexible couplings. Selecting the right rubber material depends on application-specific factors such as exposure to chemicals, temperature range, and mechanical stress requirements.

Fluoroelastomer vs Polyurethane Rubber Infographic

materialdif.com

materialdif.com