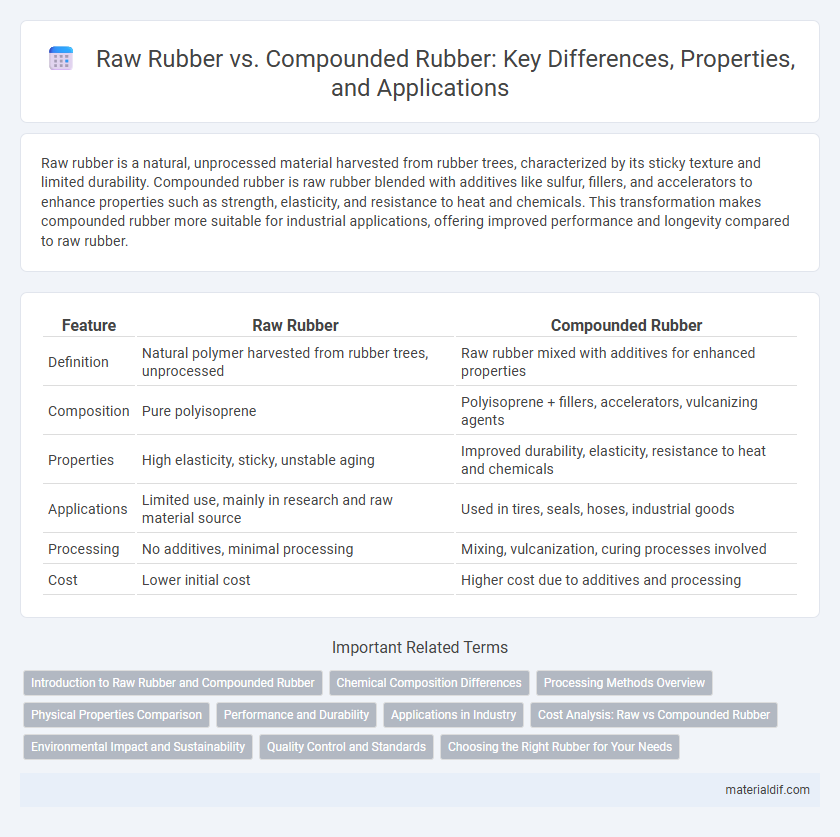

Raw rubber is a natural, unprocessed material harvested from rubber trees, characterized by its sticky texture and limited durability. Compounded rubber is raw rubber blended with additives like sulfur, fillers, and accelerators to enhance properties such as strength, elasticity, and resistance to heat and chemicals. This transformation makes compounded rubber more suitable for industrial applications, offering improved performance and longevity compared to raw rubber.

Table of Comparison

| Feature | Raw Rubber | Compounded Rubber |

|---|---|---|

| Definition | Natural polymer harvested from rubber trees, unprocessed | Raw rubber mixed with additives for enhanced properties |

| Composition | Pure polyisoprene | Polyisoprene + fillers, accelerators, vulcanizing agents |

| Properties | High elasticity, sticky, unstable aging | Improved durability, elasticity, resistance to heat and chemicals |

| Applications | Limited use, mainly in research and raw material source | Used in tires, seals, hoses, industrial goods |

| Processing | No additives, minimal processing | Mixing, vulcanization, curing processes involved |

| Cost | Lower initial cost | Higher cost due to additives and processing |

Introduction to Raw Rubber and Compounded Rubber

Raw rubber is a natural polymer harvested primarily from Hevea brasiliensis trees, characterized by its high elasticity and tackiness but limited durability. Compounded rubber consists of raw rubber blended with additives such as fillers, accelerators, and curing agents to enhance properties like strength, abrasion resistance, and aging stability. The transformation from raw to compounded rubber is essential for tailoring material performance to meet diverse industrial application requirements.

Chemical Composition Differences

Raw rubber primarily consists of polyisoprene molecules with minimal additives, exhibiting natural polymers with high elasticity and impurity content such as proteins and lipids. Compounded rubber includes a blend of raw rubber with specific chemicals like sulfur for vulcanization, carbon black for reinforcement, and antioxidants to enhance durability and performance characteristics. These chemical modifications alter the molecular cross-link density, significantly improving mechanical strength, thermal stability, and resistance to chemicals compared to raw rubber.

Processing Methods Overview

Raw rubber, derived directly from latex sap, undergoes minimal processing and maintains its natural polymer structure, making it soft and sticky. Compounded rubber involves blending raw rubber with additives such as fillers, accelerators, and stabilizers to enhance properties like durability, elasticity, and resistance to heat or chemicals. Processing methods for compounded rubber include mixing, mastication, and vulcanization, which cross-link polymer chains to achieve specific performance characteristics required for industrial applications.

Physical Properties Comparison

Raw rubber exhibits high elasticity and excellent tensile strength but lacks resistance to abrasion and weathering. Compounded rubber incorporates additives like fillers, plasticizers, and curing agents to enhance hardness, durability, and resistance to heat and chemicals. This modification improves abrasion resistance, reduces brittleness, and tailors physical properties for specific industrial applications.

Performance and Durability

Raw rubber exhibits excellent elasticity and flexibility but tends to degrade quickly under environmental stress, limiting its durability. Compounded rubber incorporates additives like fillers, plasticizers, and vulcanizing agents, significantly enhancing performance attributes such as tensile strength, abrasion resistance, and weatherability. The tailored chemical composition of compounded rubber offers superior longevity and reliability in industrial applications compared to raw rubber.

Applications in Industry

Raw rubber, primarily harvested as natural latex, serves as the foundational material in industries such as tire manufacturing and adhesives due to its elasticity and resilience. Compounded rubber, enhanced with additives like carbon black, sulfur, and accelerators, is tailored for applications requiring specific mechanical properties including automotive parts, seals, and industrial hoses. The ability to customize compounded rubber's hardness, durability, and chemical resistance makes it indispensable in aerospace, construction, and medical device industries.

Cost Analysis: Raw vs Compounded Rubber

Raw rubber typically incurs lower initial costs due to minimal processing requirements, whereas compounded rubber involves higher expenses stemming from additives, mixing, and curing processes. However, compounded rubber offers enhanced properties such as improved durability, elasticity, and resistance, leading to better long-term value and reduced maintenance costs. The cost analysis should weigh upfront savings of raw rubber against the performance benefits and lifecycle cost efficiency of compounded rubber in specific applications.

Environmental Impact and Sustainability

Raw rubber, derived directly from latex sap of rubber trees, offers a biodegradable and renewable resource with minimal chemical processing, leading to a lower environmental footprint compared to compounded rubber. Compounded rubber involves mixing raw rubber with synthetic additives and fillers, often derived from petrochemicals, which increases its durability but also results in higher carbon emissions and challenges in recycling. Sustainable practices in raw rubber harvesting, such as agroforestry and reduced chemical use, promote ecosystem preservation and carbon sequestration, whereas advancements in eco-friendly compounding aim to reduce the environmental impact of synthetic additives.

Quality Control and Standards

Raw rubber requires stringent quality control measures to ensure consistency in purity, molecular weight, and viscosity, which directly impact its performance in manufacturing processes. Compounded rubber undergoes rigorous testing for hardness, tensile strength, and elasticity to meet industry standards such as ASTM D2000 and ISO 2394, ensuring it performs reliably under specified conditions. Adhering to these quality control protocols enhances product durability and safety across automotive, industrial, and consumer applications.

Choosing the Right Rubber for Your Needs

Raw rubber offers high elasticity and excellent resilience but lacks durability and resistance to environmental factors, making it suitable for basic applications and custom compounding. Compounded rubber is enhanced with fillers, accelerators, and other additives, providing improved strength, flexibility, and resistance to heat, chemicals, and wear, ideal for industrial and specialized uses. Choosing the right rubber depends on balancing performance requirements, environmental exposure, and cost-effectiveness for the intended application.

Raw Rubber vs Compounded Rubber Infographic

materialdif.com

materialdif.com