Fluoroelastomers offer superior chemical resistance, high-temperature stability, and excellent durability compared to chloroprene rubber, making them ideal for automotive and aerospace applications. Chloroprene rubber, also known as neoprene, provides good weather, ozone, and oil resistance at a lower cost, which suits general industrial and construction uses. Choosing between fluoroelastomer and chloroprene depends on specific performance requirements, budget constraints, and environmental conditions.

Table of Comparison

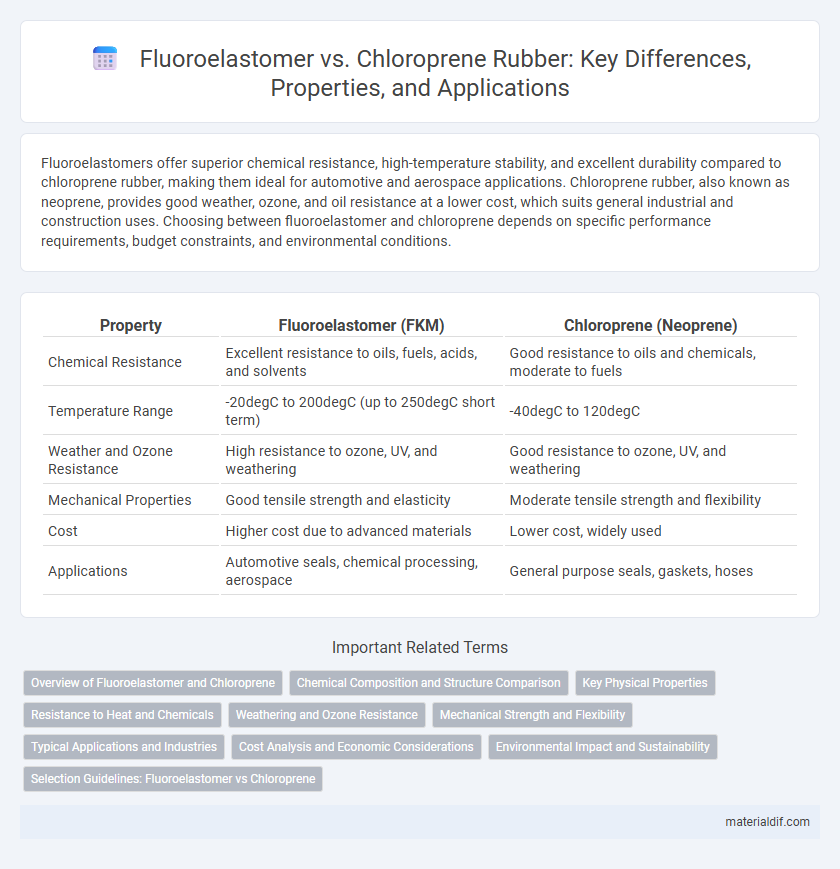

| Property | Fluoroelastomer (FKM) | Chloroprene (Neoprene) |

|---|---|---|

| Chemical Resistance | Excellent resistance to oils, fuels, acids, and solvents | Good resistance to oils and chemicals, moderate to fuels |

| Temperature Range | -20degC to 200degC (up to 250degC short term) | -40degC to 120degC |

| Weather and Ozone Resistance | High resistance to ozone, UV, and weathering | Good resistance to ozone, UV, and weathering |

| Mechanical Properties | Good tensile strength and elasticity | Moderate tensile strength and flexibility |

| Cost | Higher cost due to advanced materials | Lower cost, widely used |

| Applications | Automotive seals, chemical processing, aerospace | General purpose seals, gaskets, hoses |

Overview of Fluoroelastomer and Chloroprene

Fluoroelastomers are high-performance synthetic rubbers characterized by exceptional chemical resistance, heat stability up to 200-250degC, and superior resistance to oils, fuels, and solvents, making them ideal for aerospace, automotive, and chemical industries. Chloroprene rubber, also known as Neoprene, offers moderate chemical resistance, good weatherability, and excellent mechanical properties, widely used in industrial gaskets, hoses, and corrosion-resistant applications. The key differences lie in fluoroelastomers' enhanced durability in extreme environments compared to chloroprene's cost-effectiveness and balanced physical properties.

Chemical Composition and Structure Comparison

Fluoroelastomers consist of copolymers containing vinylidene fluoride and hexafluoropropylene, characterized by carbon-fluorine bonds that provide exceptional chemical resistance and thermal stability. Chloroprene rubber (CR) is synthesized from chloroprene monomers featuring conjugated diene structures with chlorine atoms, offering good flexibility and moderate resistance to oils and chemicals. The fluorine atoms in fluoroelastomers create a highly stable, non-polar molecular structure, whereas chloroprene's chlorinated backbone imparts moderate polarity and resilience but lower chemical resistance compared to fluoroelastomers.

Key Physical Properties

Fluoroelastomers exhibit superior chemical resistance, higher temperature tolerance up to 200degC, and excellent compression set properties compared to chloroprene rubber. Chloroprene offers moderate resistance to oils and weathering, with temperature stability typically up to 120degC and good mechanical strength. These differences make fluoroelastomers ideal for harsh environments requiring durability, while chloroprene suits general-purpose applications with balanced physical properties.

Resistance to Heat and Chemicals

Fluoroelastomers offer superior resistance to heat, maintaining stability at temperatures up to 200-250degC, whereas chloroprene typically withstands heat only up to 120-130degC. Chemically, fluoroelastomers exhibit exceptional resistance to a broad range of solvents, fuels, and acids, outperforming chloroprene which tends to degrade when exposed to harsh chemicals and oils. This makes fluoroelastomers ideal for demanding environments that require durability against extreme thermal and chemical exposure.

Weathering and Ozone Resistance

Fluoroelastomer exhibits superior weathering and ozone resistance compared to chloroprene rubber, maintaining elasticity and strength under prolonged exposure to UV rays, ozone, and harsh environmental conditions. Chloroprene rubber tends to degrade faster with cracking and surface oxidation when exposed to ozone and sunlight, limiting its use in demanding outdoor applications. This enhanced durability makes fluoroelastomer ideal for automotive seals, gaskets, and aerospace components requiring long-term resistance to oxidative aging.

Mechanical Strength and Flexibility

Fluoroelastomers exhibit superior mechanical strength compared to chloroprene rubber due to their enhanced resistance to heat, chemicals, and compression set, making them ideal for demanding industrial applications. Chloroprene rubber offers greater flexibility and elasticity at lower temperatures, which benefits dynamic sealing and cushioning uses where pliability is crucial. The choice between fluoroelastomer and chloroprene hinges on balancing the need for exceptional durability against the requirement for sustained flexibility under varying operational conditions.

Typical Applications and Industries

Fluoroelastomers are widely used in aerospace, automotive, and chemical processing industries due to their exceptional resistance to heat, fuels, and aggressive chemicals, making them ideal for seals, gaskets, and hoses in harsh environments. Chloroprene rubber, known for versatility and weather resistance, finds typical applications in automotive parts, adhesives, and coatings, as well as in construction and marine industries. Both materials serve critical roles in manufacturing, with fluoroelastomers favored for high-performance sealing solutions and chloroprene used in products requiring moderate chemical and weather resistance.

Cost Analysis and Economic Considerations

Fluoroelastomers typically exhibit higher material costs compared to chloroprene rubber, attributed to their superior chemical resistance and thermal stability, making them suitable for specialized industrial applications. Chloroprene rubber offers a more cost-effective solution with balanced durability and elasticity, often preferred in general-purpose products with moderate performance requirements. Economic considerations weigh heavily on application demands, where the upfront investment in fluoroelastomers is justified by extended service life and lower maintenance expenses, while chloroprene remains advantageous for budget-sensitive projects.

Environmental Impact and Sustainability

Fluoroelastomers exhibit superior chemical resistance and durability, resulting in longer product lifespans and reduced waste, but their manufacturing process involves fluorinated compounds that can pose environmental challenges due to persistence and potential bioaccumulation. Chloroprene rubber, while easier to recycle and derived from petrochemical sources, releases higher amounts of volatile organic compounds (VOCs) and greenhouse gases during production, impacting air quality and contributing to carbon emissions. Sustainable alternatives prioritize the reduction of hazardous emissions and enhancement of recyclability, pushing innovation toward bio-based and less toxic elastomers.

Selection Guidelines: Fluoroelastomer vs Chloroprene

Fluoroelastomer is preferred in applications requiring superior chemical resistance, high temperature stability up to 200-250degC, and excellent weathering performance, making it ideal for automotive, aerospace, and chemical processing industries. Chloroprene rubber offers moderate chemical resistance, good flexibility, and cost-effectiveness, suitable for general-purpose sealing, gaskets, and hoses operating below 120degC. Selection between fluoroelastomer and chloroprene hinges on specific exposure conditions, temperature requirements, and budget constraints, with fluoroelastomer favored for aggressive environments and chloroprene for less demanding applications.

Fluoroelastomer vs Chloroprene Infographic

materialdif.com

materialdif.com