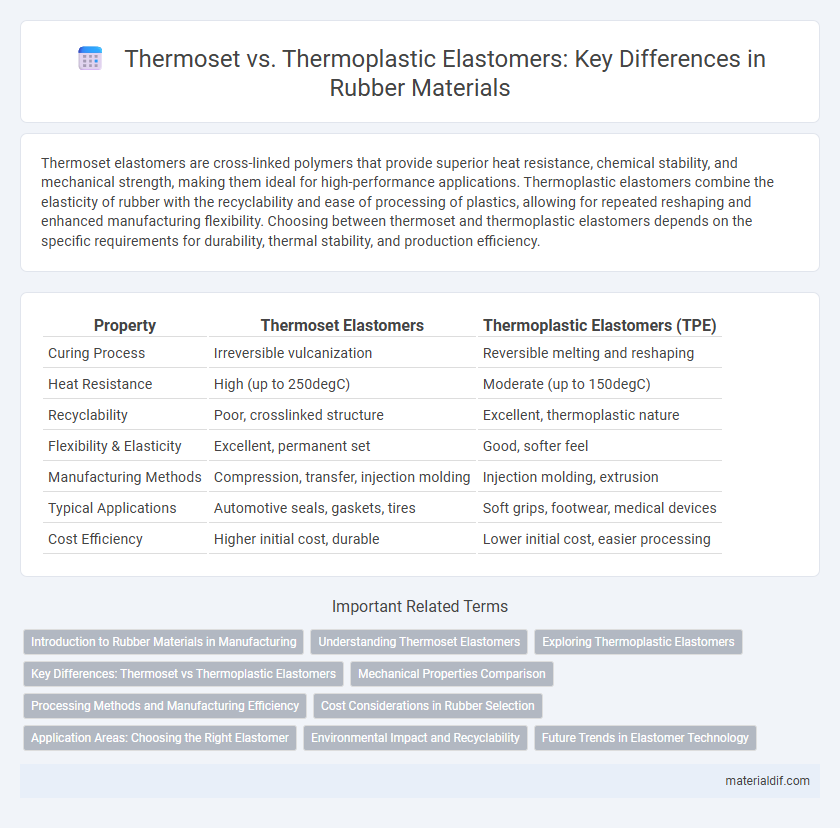

Thermoset elastomers are cross-linked polymers that provide superior heat resistance, chemical stability, and mechanical strength, making them ideal for high-performance applications. Thermoplastic elastomers combine the elasticity of rubber with the recyclability and ease of processing of plastics, allowing for repeated reshaping and enhanced manufacturing flexibility. Choosing between thermoset and thermoplastic elastomers depends on the specific requirements for durability, thermal stability, and production efficiency.

Table of Comparison

| Property | Thermoset Elastomers | Thermoplastic Elastomers (TPE) |

|---|---|---|

| Curing Process | Irreversible vulcanization | Reversible melting and reshaping |

| Heat Resistance | High (up to 250degC) | Moderate (up to 150degC) |

| Recyclability | Poor, crosslinked structure | Excellent, thermoplastic nature |

| Flexibility & Elasticity | Excellent, permanent set | Good, softer feel |

| Manufacturing Methods | Compression, transfer, injection molding | Injection molding, extrusion |

| Typical Applications | Automotive seals, gaskets, tires | Soft grips, footwear, medical devices |

| Cost Efficiency | Higher initial cost, durable | Lower initial cost, easier processing |

Introduction to Rubber Materials in Manufacturing

Thermoset elastomers such as vulcanized rubber provide enhanced durability and heat resistance through irreversible cross-linking, making them ideal for high-stress manufacturing applications like automotive tires and seals. Thermoplastic elastomers (TPEs), combining rubber's elasticity with thermoplastics' recyclability, offer versatility and ease of processing in products like flexible tubing and soft-touch grips. Selecting between thermoset and thermoplastic elastomers depends on factors including mechanical properties, environmental resistance, and production efficiency in rubber-based manufacturing.

Understanding Thermoset Elastomers

Thermoset elastomers are cross-linked polymers that form irreversible chemical bonds during curing, resulting in materials with high thermal stability and excellent resistance to deformation under heat and stress. These elastomers maintain their shape and mechanical properties even at elevated temperatures, making them ideal for applications requiring durability and long-term performance, such as automotive seals and industrial gaskets. Unlike thermoplastic elastomers, thermoset elastomers cannot be remelted or reshaped after curing, ensuring superior chemical resistance and structural integrity in demanding environments.

Exploring Thermoplastic Elastomers

Thermoplastic elastomers (TPEs) combine the elastic properties of rubber with the processability of thermoplastics, enabling versatile applications in automotive, medical, and consumer goods industries. Unlike thermoset rubbers, TPEs soften upon heating and can be remolded multiple times without significant degradation, enhancing recyclability and manufacturing efficiency. Their blend of polymers allows tailored mechanical properties, such as flexibility, durability, and chemical resistance, making them an innovative alternative to traditional vulcanized rubber.

Key Differences: Thermoset vs Thermoplastic Elastomers

Thermoset elastomers are crosslinked polymers that undergo irreversible curing, resulting in a rigid, heat-resistant rubber ideal for high-performance applications such as automotive seals and industrial gaskets. Thermoplastic elastomers (TPEs) consist of non-crosslinked polymers, allowing them to be reshaped and recycled through melting, which offers advantages in manufacturing flexibility and environmental sustainability. Key differences include thermosets' superior thermal stability and chemical resistance, contrasted with TPEs' ease of processing and recyclability.

Mechanical Properties Comparison

Thermoset elastomers exhibit superior mechanical strength, high resistance to deformation, and excellent thermal stability due to their cross-linked polymer network, making them ideal for high-stress applications. Thermoplastic elastomers (TPEs) offer enhanced flexibility, easier processability, and better impact resistance, with mechanical properties that allow repeated reshaping without significant degradation. In terms of tensile strength, thermosets typically outperform TPEs, though TPEs provide improved elongation at break and fatigue resistance, balancing durability with versatility.

Processing Methods and Manufacturing Efficiency

Thermoset elastomers undergo irreversible curing through heat or chemical reactions, resulting in a cross-linked molecular structure that enhances durability but requires longer molding cycles and limits recyclability. Thermoplastic elastomers (TPEs) can be processed using conventional thermoplastic methods such as injection molding and extrusion, offering faster cycle times and easier recycling due to their reversible melting behavior. Manufacturing efficiency improves with TPEs by reducing energy consumption and enabling high-throughput production without the need for complex vulcanization steps typical of thermoset rubber processing.

Cost Considerations in Rubber Selection

Thermoset elastomers typically involve higher initial processing costs due to curing cycles and mold preparation, but they offer superior durability and chemical resistance that can lower long-term maintenance expenses. Thermoplastic elastomers (TPEs) provide cost advantages through faster production speeds, recyclability, and reduced tooling requirements, making them ideal for high-volume applications or where design flexibility is critical. Budget decisions in rubber selection should weigh the upfront investment of thermosets against the operational savings and adaptability offered by TPEs to optimize total cost of ownership.

Application Areas: Choosing the Right Elastomer

Thermoset elastomers are ideal for high-temperature applications such as automotive seals, electrical insulation, and industrial gaskets due to their excellent heat resistance and mechanical strength. Thermoplastic elastomers excel in consumer goods, medical devices, and flexible tubing where recyclability and ease of processing are critical. Selecting the right elastomer depends on specific application requirements including temperature tolerance, durability, and manufacturing complexity.

Environmental Impact and Recyclability

Thermoset rubber exhibits high durability but poses significant environmental challenges due to its cross-linked structure, which makes recycling difficult and leads to increased landfill waste. Thermoplastic elastomers (TPEs) offer enhanced recyclability through remelting and reshaping processes, reducing environmental impact by enabling material reuse and lowering resource consumption. The choice between thermoset and TPE materials significantly influences sustainability efforts in rubber manufacturing and waste management.

Future Trends in Elastomer Technology

Future trends in elastomer technology emphasize advancements in thermoset and thermoplastic elastomers, with increased focus on sustainability and recyclability. Innovations in bio-based raw materials and enhanced processing techniques aim to improve the mechanical properties and environmental impact of both elastomer types. Emerging applications in automotive, aerospace, and wearable electronics drive the development of high-performance, lightweight elastomers with greater thermal stability and durability.

Thermoset vs Thermoplastic Elastomers Infographic

materialdif.com

materialdif.com