Compression molding involves placing pre-measured rubber into a heated mold cavity where it is compressed and cured, making it ideal for large, simple parts with low to medium production volume. Injection molding forces heated rubber into a mold under high pressure, enabling faster cycle times and greater precision for complex, high-volume parts. Both methods offer unique advantages depending on part design, production scale, and desired material properties.

Table of Comparison

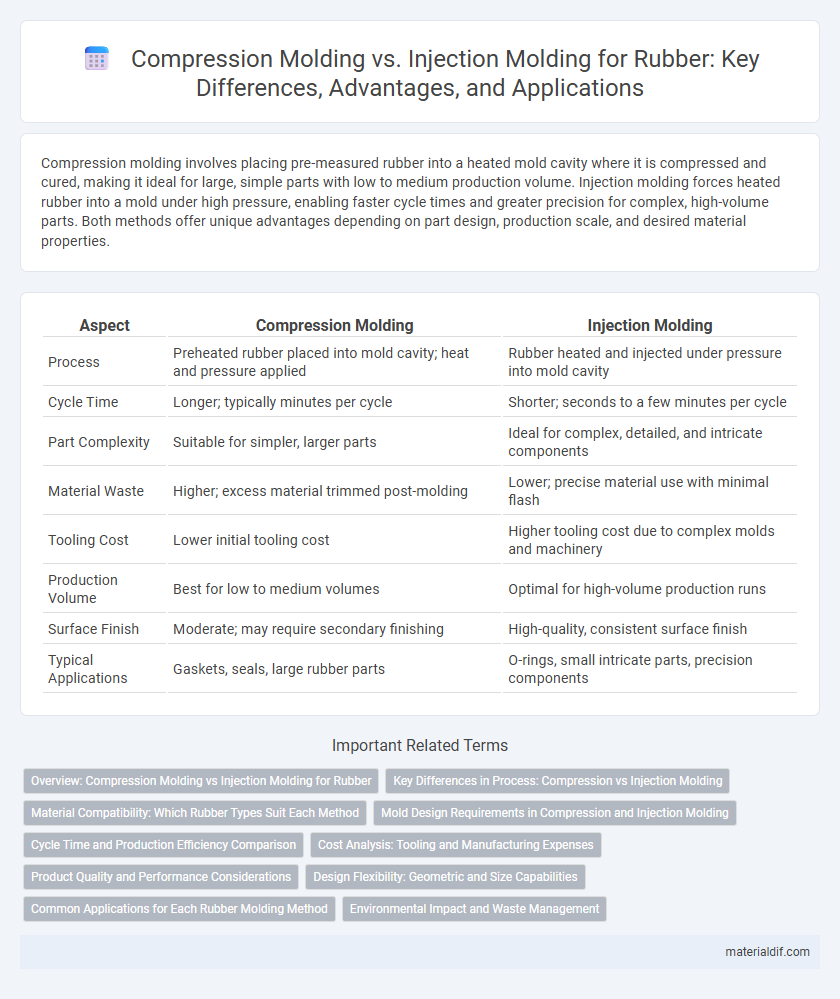

| Aspect | Compression Molding | Injection Molding |

|---|---|---|

| Process | Preheated rubber placed into mold cavity; heat and pressure applied | Rubber heated and injected under pressure into mold cavity |

| Cycle Time | Longer; typically minutes per cycle | Shorter; seconds to a few minutes per cycle |

| Part Complexity | Suitable for simpler, larger parts | Ideal for complex, detailed, and intricate components |

| Material Waste | Higher; excess material trimmed post-molding | Lower; precise material use with minimal flash |

| Tooling Cost | Lower initial tooling cost | Higher tooling cost due to complex molds and machinery |

| Production Volume | Best for low to medium volumes | Optimal for high-volume production runs |

| Surface Finish | Moderate; may require secondary finishing | High-quality, consistent surface finish |

| Typical Applications | Gaskets, seals, large rubber parts | O-rings, small intricate parts, precision components |

Overview: Compression Molding vs Injection Molding for Rubber

Compression molding for rubber involves placing pre-measured material into a heated mold cavity, where pressure and heat cause it to cure into the desired shape, offering cost-effectiveness and suitability for large, simple parts. Injection molding injects rubber material into a mold under high pressure, enabling high precision, faster cycle times, and complex geometries with consistent quality. Selection between these methods depends on production volume, part complexity, and material properties crucial for optimizing performance and manufacturing efficiency.

Key Differences in Process: Compression vs Injection Molding

Compression molding involves placing pre-measured rubber into a heated mold cavity where pressure shapes the material, while injection molding forces heated rubber through a nozzle into a closed mold under high pressure. Compression molding typically suits large, simple parts with lower tooling costs, whereas injection molding offers higher precision and faster cycle times for complex shapes. Key differences include the method of material introduction, pressure application, and mold design, influencing production speed, part complexity, and cost-efficiency in rubber manufacturing.

Material Compatibility: Which Rubber Types Suit Each Method

Silicone rubber and thermoplastic elastomers are ideal for injection molding due to their excellent flow properties and precise molding capabilities. Natural rubber and EPDM (ethylene propylene diene monomer) are better suited for compression molding, which accommodates their higher viscosity and vulcanization needs. Fluoroelastomers and nitrile rubber can be processed with both methods, but their specific formulation and production volume dictate the preferred molding technique.

Mold Design Requirements in Compression and Injection Molding

Compression molding requires molds designed to withstand high pressure and temperature, with precise cavity dimensions to accommodate pre-measured rubber compounds that expand during curing. Injection molding demands complex mold designs featuring intricate runners, gates, and vents to facilitate the high-speed flow of liquid rubber into detailed cavities, ensuring uniform filling and minimal flash. Both mold types must provide efficient heat transfer and durability to handle repetitive production cycles for optimal rubber part quality.

Cycle Time and Production Efficiency Comparison

Compression molding offers longer cycle times compared to injection molding due to the slower heating and curing process involved in shaping rubber. Injection molding enables faster cycle times by injecting heated rubber directly into molds, significantly boosting production efficiency for high-volume runs. Manufacturers prioritize injection molding when rapid throughput and consistent part quality are critical for large-scale rubber component production.

Cost Analysis: Tooling and Manufacturing Expenses

Compression molding typically involves lower tooling costs due to simpler molds and less complex machinery, making it more economical for small to medium production runs. Injection molding requires higher initial investment in precision molds and automated equipment but offers faster cycle times and reduced labor costs, benefiting large-scale manufacturing. Evaluating manufacturing expenses reveals compression molding's cost-effectiveness for low volume, while injection molding provides long-term savings through efficiency in mass production of rubber components.

Product Quality and Performance Considerations

Compression molding offers superior control over material flow and pressure, resulting in rubber products with enhanced tensile strength and dimensional stability. Injection molding provides high precision and repeatability, producing complex geometries with consistent surface finish and minimal flash defects. Choosing between these methods depends on specific performance requirements such as flexibility, durability, and production volume demands.

Design Flexibility: Geometric and Size Capabilities

Compression molding offers superior design flexibility for large, simple geometric rubber parts due to its ability to handle complex, thick sections with uniform material flow. Injection molding excels in producing intricate, precise rubber components with tight tolerances and fine details, making it ideal for small to medium-sized parts. Both methods accommodate varying sizes, but injection molding enables higher repeatability for complex shapes, while compression molding suits bulkier, less detailed designs.

Common Applications for Each Rubber Molding Method

Compression molding is commonly used for producing large, durable rubber products such as seals, gaskets, and automotive components due to its ability to handle high-strength compounds and thick parts. Injection molding is ideal for high-volume manufacturing of complex, precise rubber parts like O-rings, medical devices, and small intricate components, benefiting from faster cycle times and excellent repeatability. Each method serves distinct industries based on part complexity, production volume, and material characteristics.

Environmental Impact and Waste Management

Compression molding of rubber generates less material waste compared to injection molding due to its precise use of pre-measured rubber blanks, minimizing off-cuts and flash. Injection molding often leads to higher scrap rates and requires more energy consumption because of its complex machinery and longer cycle times. Waste from compression molding can be more easily recycled or repurposed, contributing to a lower overall environmental footprint relative to the injection molding process.

Compression Molding vs Injection Molding (for rubber) Infographic

materialdif.com

materialdif.com