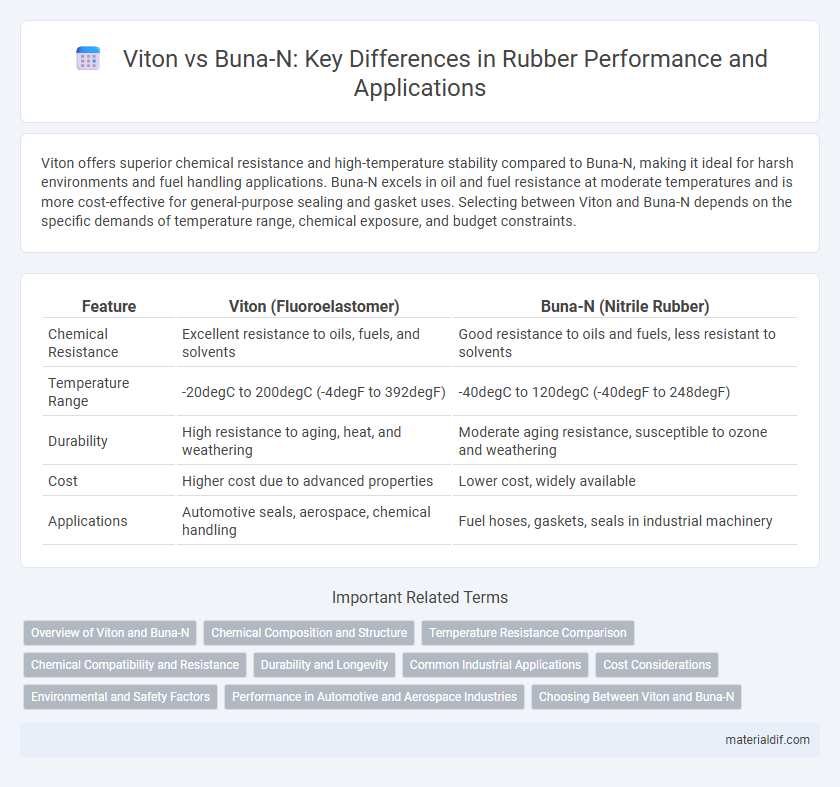

Viton offers superior chemical resistance and high-temperature stability compared to Buna-N, making it ideal for harsh environments and fuel handling applications. Buna-N excels in oil and fuel resistance at moderate temperatures and is more cost-effective for general-purpose sealing and gasket uses. Selecting between Viton and Buna-N depends on the specific demands of temperature range, chemical exposure, and budget constraints.

Table of Comparison

| Feature | Viton (Fluoroelastomer) | Buna-N (Nitrile Rubber) |

|---|---|---|

| Chemical Resistance | Excellent resistance to oils, fuels, and solvents | Good resistance to oils and fuels, less resistant to solvents |

| Temperature Range | -20degC to 200degC (-4degF to 392degF) | -40degC to 120degC (-40degF to 248degF) |

| Durability | High resistance to aging, heat, and weathering | Moderate aging resistance, susceptible to ozone and weathering |

| Cost | Higher cost due to advanced properties | Lower cost, widely available |

| Applications | Automotive seals, aerospace, chemical handling | Fuel hoses, gaskets, seals in industrial machinery |

Overview of Viton and Buna-N

Viton is a fluoroelastomer known for its exceptional chemical resistance, high-temperature stability up to 200degC, and excellent durability in harsh environments. Buna-N, also called nitrile rubber, offers strong resistance to oils, fuels, and other petroleum-based products, with operational temperatures typically ranging from -40degC to 120degC. Both materials are widely used in automotive and industrial applications, with Viton preferred for high-heat and aggressive chemical exposure, while Buna-N is favored for its cost-effectiveness and oil resistance.

Chemical Composition and Structure

Viton is a fluorocarbon-based synthetic rubber composed primarily of vinylidene fluoride and hexafluoropropylene, providing exceptional resistance to fuels, oils, and chemicals due to its saturated fluoropolymer backbone. Buna-N, or nitrile rubber, consists mainly of acrylonitrile and butadiene, featuring a copolymer structure that offers strong resistance to oils and fuels but lower chemical stability compared to Viton. The chemical composition of Viton gives it superior thermal stability and chemical resistance, while Buna-N's nitrile groups enhance abrasion resistance and flexibility in lower temperature applications.

Temperature Resistance Comparison

Viton rubber exhibits exceptional temperature resistance, maintaining stability in continuous use from -20degC to 200degC and short-term exposure up to 250degC, making it ideal for high-heat applications. Buna-N (Nitrile) rubber typically withstands temperatures between -40degC and 108degC, with some formulations tolerating up to 135degC, suitable for moderate heat environments. The superior thermal endurance of Viton allows it to perform reliably in automotive, aerospace, and industrial settings where Buna-N's temperature limits would result in degradation.

Chemical Compatibility and Resistance

Viton offers superior chemical resistance compared to Buna-N, excelling in environments with exposure to fuels, oils, and aggressive chemicals like acids and solvents. Buna-N, also known as nitrile rubber, is highly resistant to petroleum-based oils and fuels but shows vulnerability to aromatic hydrocarbons and ketones. Viton's fluoroelastomer composition ensures outstanding performance in high-temperature settings and harsh chemical conditions, making it the preferred choice for industrial seals and gaskets requiring long-term durability.

Durability and Longevity

Viton rubber exhibits superior durability and longevity compared to Buna-N, especially under high-temperature conditions and exposure to harsh chemicals. Viton maintains its elasticity and resists degradation in temperatures ranging from -20degC to 200degC, making it ideal for automotive and aerospace applications. Buna-N, while offering good resistance to oils and fuels, generally has a lower thermal stability and shorter lifespan in extreme environments.

Common Industrial Applications

Viton excels in high-temperature and chemical-resistant applications such as fuel hoses, seals, and gaskets in automotive and aerospace industries due to its superior fluorocarbon composition. Buna-N (Nitrile) is widely used in oil and gas, hydraulic systems, and fuel handling where excellent resistance to petroleum-based oils and fuels is critical. Both elastomers serve essential roles in industrial environments, with Viton preferred for extreme chemical and thermal conditions while Buna-N offers cost-effective durability in oil exposure scenarios.

Cost Considerations

Viton rubber typically commands a higher price than Buna-N due to its superior chemical resistance and high-temperature tolerance, making it ideal for demanding industrial applications. Buna-N offers a cost-effective alternative with excellent oil and fuel resistance, suitable for less extreme environments. Cost considerations should weigh the performance requirements against budget constraints to determine the most economical choice for sealing and gasket applications.

Environmental and Safety Factors

Viton, a fluorocarbon rubber, offers superior chemical resistance and high-temperature stability, making it safer for use in harsh industrial environments with exposure to fuels, oils, and aggressive chemicals. Buna-N (Nitrile) excels in oil resistance and has better abrasion resistance but performs poorly in ozone, weathering, and certain chemical exposures, limiting its environmental durability. Viton's lower permeability to gases and resistance to environmental degradation reduces hazardous emissions, enhancing safety in applications requiring prolonged chemical exposure.

Performance in Automotive and Aerospace Industries

Viton outperforms Buna-N in automotive and aerospace applications due to its superior heat resistance up to 400degF (204degC) and exceptional chemical stability against fuels, oils, and hydraulic fluids. Buna-N, known for its excellent resistance to petroleum-based oils and fuels, operates effectively within a temperature range of -40degF to 250degF (-40degC to 121degC), making it suitable for less demanding environments. Viton's ability to maintain elasticity and durability under extreme temperatures and aggressive chemical exposure makes it the preferred choice for critical aerospace seals and high-performance automotive gaskets.

Choosing Between Viton and Buna-N

Choosing between Viton and Buna-N depends on chemical resistance and temperature requirements; Viton excels in high-temperature applications up to 204degC and offers superior resistance to fuels, oils, and aggressive chemicals, making it ideal for automotive and aerospace industries. Buna-N, also known as nitrile rubber, provides excellent resistance to petroleum-based oils and fuels but has a lower temperature range, typically up to 121degC, making it suitable for general-purpose seals and gaskets in hydraulic systems. Selecting the right material involves balancing cost, durability, and the specific environmental conditions of the application.

Viton vs Buna-N Infographic

materialdif.com

materialdif.com