Flame-retardant rubber offers enhanced safety by resisting ignition and slowing the spread of fire, making it ideal for applications requiring stringent fire protection standards. General-purpose rubber lacks these specific properties, prioritizing flexibility and durability over flame resistance. Choosing flame-retardant rubber ensures compliance with safety regulations in environments prone to fire hazards.

Table of Comparison

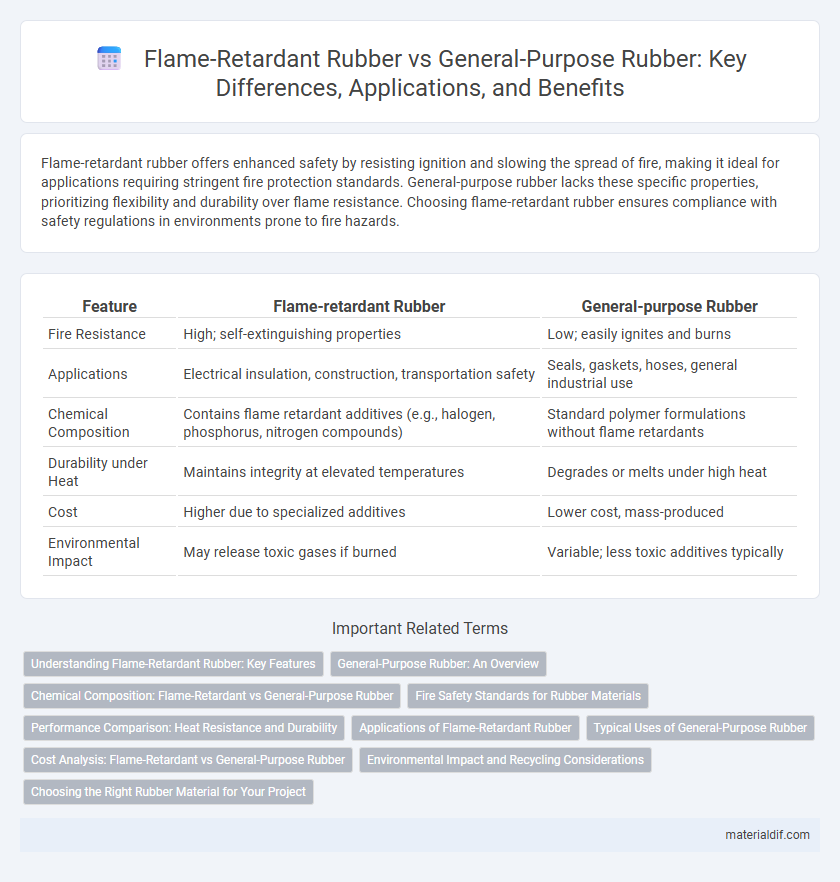

| Feature | Flame-retardant Rubber | General-purpose Rubber |

|---|---|---|

| Fire Resistance | High; self-extinguishing properties | Low; easily ignites and burns |

| Applications | Electrical insulation, construction, transportation safety | Seals, gaskets, hoses, general industrial use |

| Chemical Composition | Contains flame retardant additives (e.g., halogen, phosphorus, nitrogen compounds) | Standard polymer formulations without flame retardants |

| Durability under Heat | Maintains integrity at elevated temperatures | Degrades or melts under high heat |

| Cost | Higher due to specialized additives | Lower cost, mass-produced |

| Environmental Impact | May release toxic gases if burned | Variable; less toxic additives typically |

Understanding Flame-Retardant Rubber: Key Features

Flame-retardant rubber is engineered with specialized additives such as halogenated compounds and phosphorus-based chemicals to inhibit ignition and reduce flame propagation. Unlike general-purpose rubber, it exhibits enhanced thermal stability, lower smoke emission, and improved resistance to high-temperature environments. These key features make flame-retardant rubber crucial for applications in electrical insulation, automotive components, and construction materials where fire safety standards are stringent.

General-Purpose Rubber: An Overview

General-purpose rubber is a versatile elastomer widely used in automotive, construction, and consumer goods due to its excellent elasticity, abrasion resistance, and cost-effectiveness. It offers reliable performance in a broad range of temperatures and environments but lacks the specialized fire resistance properties found in flame-retardant rubber. Common types include natural rubber (NR), styrene-butadiene rubber (SBR), and nitrile rubber (NBR), each chosen based on specific mechanical and chemical resistance requirements.

Chemical Composition: Flame-Retardant vs General-Purpose Rubber

Flame-retardant rubber contains chemical additives such as halogenated compounds, phosphorus-based agents, or metal hydroxides like aluminum trihydrate to inhibit combustion and reduce flammability. General-purpose rubber primarily consists of natural or synthetic polymers like styrene-butadiene or natural latex without flame-retardant additives, making it more susceptible to burning. The inclusion of these specific flame-retardant chemicals significantly alters the molecular structure and thermal degradation pathways, enhancing fire resistance compared to general-purpose rubber.

Fire Safety Standards for Rubber Materials

Flame-retardant rubber meets stringent fire safety standards such as UL 94 and ASTM E84, which regulate material combustibility, smoke generation, and flame spread to enhance fire resistance. General-purpose rubber typically lacks these certifications, making it more susceptible to ignition and rapid flame propagation under fire conditions. Compliance with established fire safety codes ensures flame-retardant rubber minimizes fire hazards in industrial and commercial applications.

Performance Comparison: Heat Resistance and Durability

Flame-retardant rubber exhibits superior heat resistance, maintaining structural integrity at temperatures exceeding 250degC compared to general-purpose rubber's tolerance of approximately 120degC. This enhanced thermal stability significantly boosts durability in high-temperature environments, reducing degradation and extending service life. The specialized chemical additives in flame-retardant rubber also improve resistance to burning and charring, resulting in safer and more reliable performance under extreme heat conditions.

Applications of Flame-Retardant Rubber

Flame-retardant rubber is extensively used in electrical insulation, automotive components, and construction materials where fire safety is critical, reducing fire risk and enhancing safety standards. Its application in cable coatings, gaskets, and seals ensures compliance with stringent fire resistance regulations in industrial and residential environments. Compared to general-purpose rubber, flame-retardant variants provide enhanced durability under high temperatures and prevent toxic smoke emission during combustion.

Typical Uses of General-Purpose Rubber

General-purpose rubber is widely used in automotive seals, gaskets, and hoses due to its excellent flexibility and resistance to wear and tear. It also serves in manufacturing footwear soles, conveyor belts, and vibration dampening components because of its durability and cost-effectiveness. Unlike flame-retardant rubber, it lacks specialized fire resistance but offers versatile performance in everyday industrial and consumer products.

Cost Analysis: Flame-Retardant vs General-Purpose Rubber

Flame-retardant rubber typically incurs higher manufacturing costs than general-purpose rubber due to specialized additives and enhanced processing requirements. The increased material expenses are offset by improved safety compliance and reduced fire risk in applications such as electrical insulation and automotive components. While general-purpose rubber offers cost efficiency for non-critical uses, flame-retardant variants justify their premium through longer service life and regulatory adherence.

Environmental Impact and Recycling Considerations

Flame-retardant rubber contains chemical additives such as halogens or phosphorus compounds that reduce flammability but can complicate recycling processes due to potential release of toxic substances. General-purpose rubber typically has fewer additives, making it easier to recycle and less harmful to the environment during disposal. Selecting rubber materials with consideration for their environmental footprint and recyclability helps minimize ecological damage and supports sustainable waste management.

Choosing the Right Rubber Material for Your Project

Flame-retardant rubber offers enhanced safety by resisting ignition and slowing combustion, making it ideal for applications in electrical insulation, automotive parts, and construction materials where fire hazards are a concern. General-purpose rubber provides excellent flexibility, durability, and cost-effectiveness for everyday uses such as seals, gaskets, and hoses but lacks specialized fire-resistant properties. Selecting the right rubber material depends on project requirements for safety standards, environmental exposure, and performance characteristics to ensure optimal functionality and compliance.

Flame-retardant Rubber vs General-purpose Rubber Infographic

materialdif.com

materialdif.com