EPDM rubber offers superior resistance to heat, ozone, and weathering, making it ideal for outdoor and automotive applications, while NBR excels in oil and fuel resistance, commonly used in fuel hoses and seals. EPDM's synthetic rubber composition ensures flexibility in low temperatures and excellent electrical insulation, whereas NBR provides strong abrasion resistance and durability against petroleum-based fluids. Choosing between EPDM and NBR depends on the specific environmental exposure and chemical compatibility required for the application.

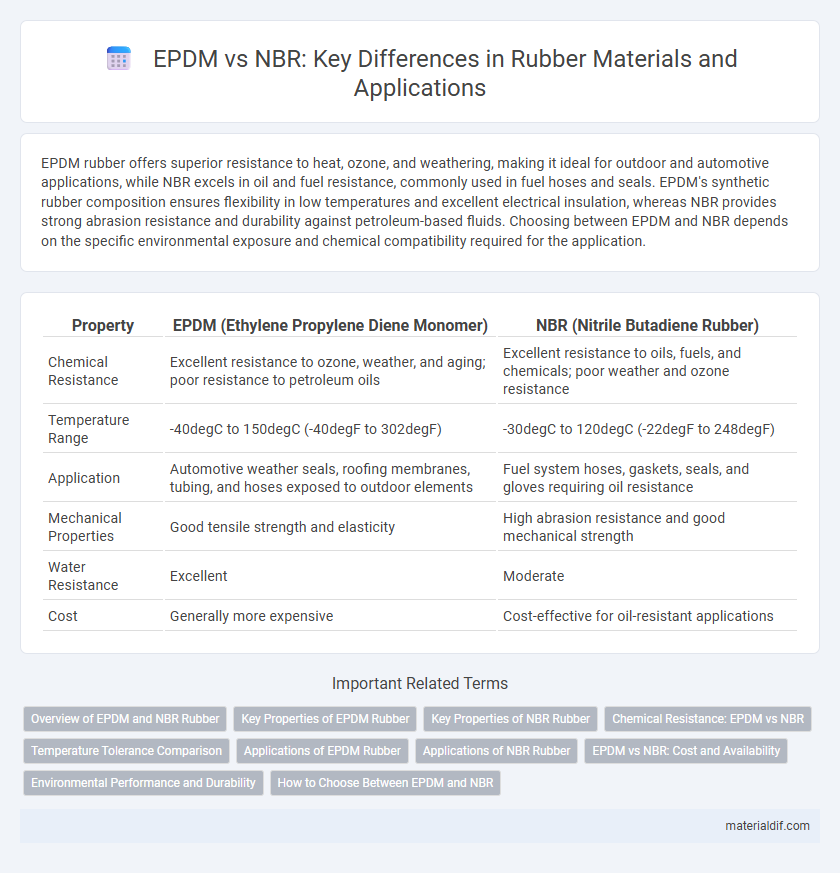

Table of Comparison

| Property | EPDM (Ethylene Propylene Diene Monomer) | NBR (Nitrile Butadiene Rubber) |

|---|---|---|

| Chemical Resistance | Excellent resistance to ozone, weather, and aging; poor resistance to petroleum oils | Excellent resistance to oils, fuels, and chemicals; poor weather and ozone resistance |

| Temperature Range | -40degC to 150degC (-40degF to 302degF) | -30degC to 120degC (-22degF to 248degF) |

| Application | Automotive weather seals, roofing membranes, tubing, and hoses exposed to outdoor elements | Fuel system hoses, gaskets, seals, and gloves requiring oil resistance |

| Mechanical Properties | Good tensile strength and elasticity | High abrasion resistance and good mechanical strength |

| Water Resistance | Excellent | Moderate |

| Cost | Generally more expensive | Cost-effective for oil-resistant applications |

Overview of EPDM and NBR Rubber

EPDM (Ethylene Propylene Diene Monomer) rubber is a synthetic elastomer known for its excellent resistance to heat, ozone, weathering, and aging, making it ideal for automotive seals, roofing membranes, and electrical insulation. NBR (Nitrile Butadiene Rubber) excels in oil and fuel resistance, providing superior performance in applications such as fuel hoses, gaskets, and seals exposed to hydrocarbons. Both EPDM and NBR offer unique chemical and physical properties tailored for specific industrial uses, with EPDM favored in outdoor and high-temperature environments while NBR is preferred for oil-resistant applications.

Key Properties of EPDM Rubber

EPDM rubber exhibits exceptional resistance to heat, ozone, and weathering, making it ideal for outdoor applications and automotive sealing systems. Its excellent electrical insulation properties and flexibility at low temperatures enhance its performance across diverse industrial uses. EPDM also shows superior resistance to steam, water, and polar chemicals, distinguishing it from NBR which excels in oil and fuel resistance.

Key Properties of NBR Rubber

Nitrile Butadiene Rubber (NBR) exhibits superior resistance to oils, fuels, and chemicals, making it ideal for automotive and industrial applications requiring durability in harsh environments. Its excellent abrasion resistance and good tensile strength enable it to maintain performance under mechanical stress and repeated flexing. NBR also offers a broad temperature tolerance, typically ranging from -40degC to 120degC, ensuring reliable operation in varying thermal conditions.

Chemical Resistance: EPDM vs NBR

EPDM rubber exhibits superior resistance to weathering, ozone, and a wide range of chemicals including acids, alkalis, and polar solvents, making it ideal for outdoor and automotive applications. NBR (Nitrile Butadiene Rubber) offers excellent resistance to oils, fuels, and hydrocarbons but degrades when exposed to ozone, oxidation, and certain chemicals like ketones and esters. Selecting EPDM over NBR is crucial when chemical exposure involves acidic or alkaline environments rather than oil-based substances.

Temperature Tolerance Comparison

EPDM rubber exhibits superior temperature tolerance, maintaining flexibility and performance in a wide range from -40degC to 150degC, making it ideal for outdoor and high-heat applications. In contrast, NBR (Nitrile Butadiene Rubber) performs efficiently between -30degC and 100degC but degrades more rapidly under prolonged exposure to high temperatures. EPDM's enhanced heat resistance ensures durability in automotive weather seals and roofing membranes where temperature extremes are common.

Applications of EPDM Rubber

EPDM rubber excels in outdoor applications due to its superior resistance to weathering, ozone, UV exposure, and extreme temperatures, making it ideal for roofing membranes, automotive weather seals, and electrical insulation. Its excellent resistance to heat and steam also suits it for use in radiator hoses, HVAC seals, and dishwasher door seals. Unlike NBR, which performs better with oils and fuels, EPDM's chemical stability makes it preferred in water and steam environments.

Applications of NBR Rubber

NBR rubber, also known as nitrile rubber, is extensively used in automotive fuel and oil handling hoses, seals, and gaskets due to its excellent resistance to petroleum-based oils and fuels. Its applications extend to industrial gloves and seals for hydraulic systems, where durability against chemicals and abrasion is critical. NBR's resistance to heat, oil, and chemicals makes it ideal for manufacturing O-rings, valve seals, and other components in the aerospace and oil industries.

EPDM vs NBR: Cost and Availability

EPDM rubber generally offers a lower cost compared to NBR, making it a cost-effective solution for large-scale applications. EPDM's widespread production and use in automotive weather seals and roofing membranes ensure high availability globally. In contrast, NBR, known for superior oil and fuel resistance, often comes at a higher price point due to specialized demand and somewhat limited supply.

Environmental Performance and Durability

EPDM rubber excels in environmental performance due to its superior resistance to UV radiation, ozone, and extreme weather conditions, making it ideal for outdoor applications requiring long-term durability. NBR, while offering excellent resistance to oils and fuels, typically has lower weathering and ozone resistance, which can reduce its lifespan in harsh environmental settings. EPDM's ability to maintain elasticity and integrity under prolonged exposure to environmental stressors ensures enhanced durability compared to NBR in most outdoor and industrial applications.

How to Choose Between EPDM and NBR

Selecting between EPDM and NBR rubber depends on the specific application environment and chemical exposure. EPDM excels in outdoor applications due to its superior resistance to UV, ozone, and weathering, while NBR offers excellent oil, fuel, and chemical resistance, making it ideal for automotive and industrial seals. Consider temperature range, compatibility with fluids, and mechanical properties to determine the best rubber type for durability and performance.

EPDM vs NBR Infographic

materialdif.com

materialdif.com