Natural rubber, harvested from the latex of rubber trees, offers exceptional elasticity, resilience, and biodegradability, making it ideal for products requiring high durability and environmental sustainability. Synthetic rubber, produced from petroleum-based polymers, provides superior resistance to heat, chemicals, and abrasion, making it suitable for industrial applications where performance consistency is critical. Selecting between natural and synthetic rubber depends on specific usage requirements, balancing factors like environmental impact, mechanical properties, and cost efficiency.

Table of Comparison

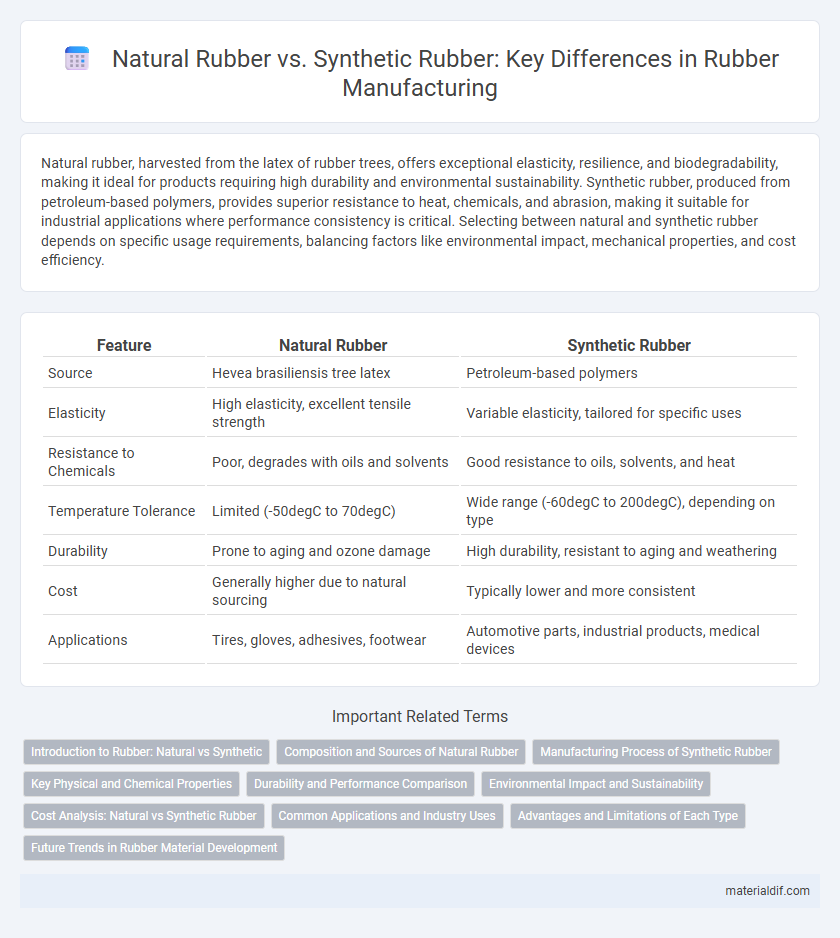

| Feature | Natural Rubber | Synthetic Rubber |

|---|---|---|

| Source | Hevea brasiliensis tree latex | Petroleum-based polymers |

| Elasticity | High elasticity, excellent tensile strength | Variable elasticity, tailored for specific uses |

| Resistance to Chemicals | Poor, degrades with oils and solvents | Good resistance to oils, solvents, and heat |

| Temperature Tolerance | Limited (-50degC to 70degC) | Wide range (-60degC to 200degC), depending on type |

| Durability | Prone to aging and ozone damage | High durability, resistant to aging and weathering |

| Cost | Generally higher due to natural sourcing | Typically lower and more consistent |

| Applications | Tires, gloves, adhesives, footwear | Automotive parts, industrial products, medical devices |

Introduction to Rubber: Natural vs Synthetic

Natural rubber, derived from the latex of rubber trees (Hevea brasiliensis), offers excellent elasticity, resilience, and biodegradability, making it ideal for applications requiring flexibility and environmental sustainability. Synthetic rubber, produced from petrochemical monomers such as styrene and butadiene, provides enhanced resistance to heat, oil, and abrasion, catering to industrial uses demanding durability and chemical stability. The choice between natural and synthetic rubber depends on performance criteria, cost considerations, and environmental impact.

Composition and Sources of Natural Rubber

Natural rubber is primarily composed of polyisoprene, a polymer derived from the latex sap of the Hevea brasiliensis tree, making it a renewable biopolymer sourced mainly from Southeast Asia. Synthetic rubber, on the other hand, is composed of various petrochemical polymers such as styrene-butadiene or polybutadiene, produced through chemical synthesis from fossil fuel derivatives. The natural rubber's unique cis-1,4-polyisoprene configuration provides superior elasticity and tensile strength compared to most synthetic alternatives.

Manufacturing Process of Synthetic Rubber

Synthetic rubber is produced through polymerization of monomers such as styrene and butadiene using methods like emulsion or solution polymerization, allowing precise control over molecular structure and properties. The manufacturing process involves initiating chain reactions with catalysts or initiators, leading to long polymer chains that form the rubber material. This controlled process enables synthetic rubber to have tailored characteristics, including enhanced durability, heat resistance, and specific elasticity compared to natural rubber.

Key Physical and Chemical Properties

Natural rubber, derived from latex of Hevea brasiliensis, exhibits high elasticity, excellent tensile strength, and superior resistance to abrasion, making it ideal for applications like tires and gloves. Synthetic rubber, produced through polymerization of petrochemical monomers such as styrene and butadiene, offers enhanced chemical resistance, temperature stability, and oil resistance compared to natural rubber. Key chemical differences include natural rubber's cis-1,4-polyisoprene structure versus synthetic variants like styrene-butadiene rubber (SBR) and nitrile rubber (NBR), which provide tailored properties for diverse industrial uses.

Durability and Performance Comparison

Natural rubber offers superior elasticity and resilience, making it highly durable under dynamic loads and ideal for applications requiring high tensile strength. Synthetic rubber, such as styrene-butadiene and neoprene, provides enhanced resistance to heat, oils, and chemicals, resulting in longer-lasting performance in harsh environments. The choice between natural and synthetic rubber depends on the specific durability requirements and operating conditions of the intended application.

Environmental Impact and Sustainability

Natural rubber is derived from the latex of rubber trees, making it a renewable and biodegradable resource with a lower carbon footprint compared to synthetic rubber, which is produced from petrochemicals. The cultivation of natural rubber supports biodiversity and carbon sequestration but can contribute to deforestation if not managed sustainably, whereas synthetic rubber relies on non-renewable fossil fuels and generates more greenhouse gas emissions during production. Sustainable practices in natural rubber farming and advances in bio-based synthetic alternatives are critical for minimizing environmental impact and promoting long-term sustainability in the rubber industry.

Cost Analysis: Natural vs Synthetic Rubber

Natural rubber typically incurs higher production costs due to labor-intensive harvesting and sensitivity to climate conditions, whereas synthetic rubber benefits from more consistent manufacturing processes and raw material availability derived from petrochemicals. Price volatility in natural rubber is influenced by agricultural factors and geopolitical events in producing countries, whereas synthetic rubber costs are more stable, linked to crude oil price fluctuations. Businesses often weigh these cost dynamics against performance requirements and supply chain stability when choosing between natural and synthetic rubber.

Common Applications and Industry Uses

Natural rubber is predominantly used in tire manufacturing, medical gloves, and adhesives due to its excellent elasticity, resilience, and biodegradability. Synthetic rubber, derived from petroleum-based monomers like styrene and butadiene, is favored in automotive parts, industrial belts, and footwear for its superior resistance to heat, oil, and aging. The automotive industry extensively relies on synthetic variants for durability, while natural rubber dominates sectors requiring flexibility and eco-friendly materials.

Advantages and Limitations of Each Type

Natural rubber offers superior elasticity, resilience, and tensile strength, making it ideal for applications requiring high flexibility and durability, but it is vulnerable to heat, aging, and chemical degradation. Synthetic rubber, such as styrene-butadiene (SBR) and nitrile rubber, provides enhanced resistance to oil, heat, and abrasion, offering better performance in harsh environments, though it often lacks the elasticity and comfort of natural rubber. Both types complement various industrial needs, with natural rubber preferred for tires and medical gloves, while synthetic variants dominate automotive parts and industrial seals.

Future Trends in Rubber Material Development

Future trends in rubber material development emphasize enhancing sustainability and performance by advancing bio-based natural rubber alternatives and engineering next-generation synthetic rubbers with improved durability and eco-friendliness. Innovations include the integration of renewable feedstocks, recycling technologies, and nanocomposites to boost mechanical properties and reduce environmental impact. The global rubber industry is increasingly investing in green chemistry and circular economy practices to meet rising demand for sustainable materials in automotive, aerospace, and consumer goods sectors.

Natural Rubber vs Synthetic Rubber Infographic

materialdif.com

materialdif.com