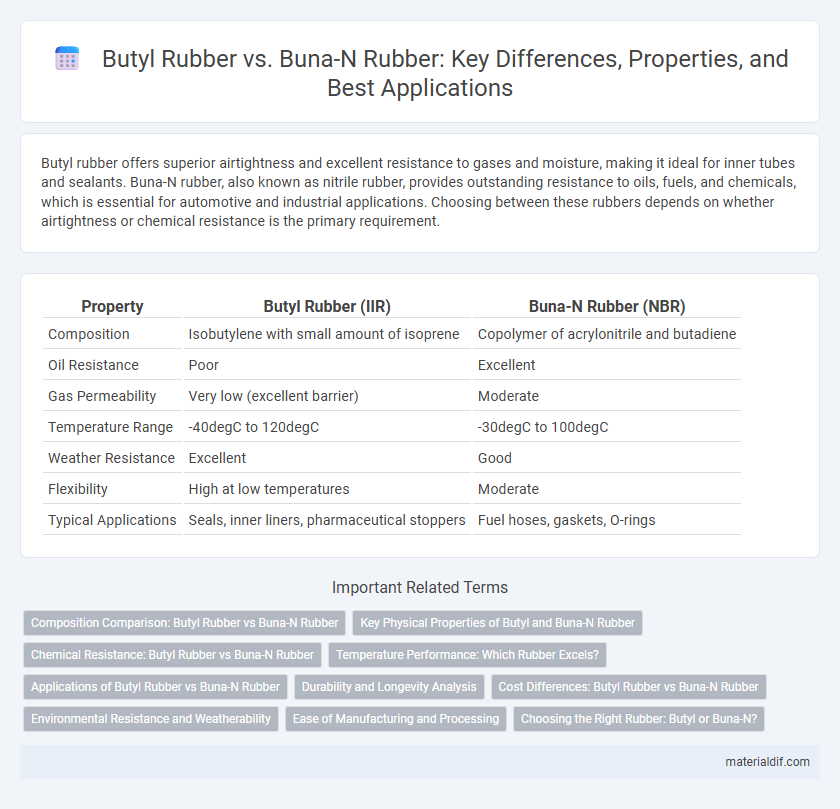

Butyl rubber offers superior airtightness and excellent resistance to gases and moisture, making it ideal for inner tubes and sealants. Buna-N rubber, also known as nitrile rubber, provides outstanding resistance to oils, fuels, and chemicals, which is essential for automotive and industrial applications. Choosing between these rubbers depends on whether airtightness or chemical resistance is the primary requirement.

Table of Comparison

| Property | Butyl Rubber (IIR) | Buna-N Rubber (NBR) |

|---|---|---|

| Composition | Isobutylene with small amount of isoprene | Copolymer of acrylonitrile and butadiene |

| Oil Resistance | Poor | Excellent |

| Gas Permeability | Very low (excellent barrier) | Moderate |

| Temperature Range | -40degC to 120degC | -30degC to 100degC |

| Weather Resistance | Excellent | Good |

| Flexibility | High at low temperatures | Moderate |

| Typical Applications | Seals, inner liners, pharmaceutical stoppers | Fuel hoses, gaskets, O-rings |

Composition Comparison: Butyl Rubber vs Buna-N Rubber

Butyl rubber is primarily composed of isobutylene with a small amount of isoprene, providing excellent impermeability to gases and superior resistance to heat and chemicals. Buna-N rubber, also known as nitrile rubber, consists of copolymers of acrylonitrile and butadiene, offering exceptional resistance to oils, fuels, and other solvents. The distinct molecular structures in butyl and Buna-N rubbers define their specific physical and chemical properties, making each suitable for different industrial applications.

Key Physical Properties of Butyl and Buna-N Rubber

Butyl rubber exhibits exceptional impermeability to gases, low permeability to chemicals, and excellent resistance to ozone and weathering, making it ideal for inner linings and sealing applications. Buna-N rubber (Nitrile) is known for its superior oil, fuel, and chemical resistance combined with good abrasion resistance and mechanical strength. While butyl excels in flexibility and air retention, Buna-N offers enhanced hardness and tensile strength, balancing performance across diverse industrial environments.

Chemical Resistance: Butyl Rubber vs Buna-N Rubber

Butyl rubber offers superior chemical resistance against gases, acids, and alkalis, making it ideal for applications requiring airtight seals and exposure to harsh chemicals. Buna-N rubber, or nitrile rubber, excels in resistance to oils, fuels, and hydrocarbons but is less effective against strong acids and alkalis compared to butyl rubber. Choosing between butyl rubber and Buna-N depends on the specific chemical environment, with butyl rubber preferred for acidic or alkaline conditions and Buna-N favored for petroleum-based substances.

Temperature Performance: Which Rubber Excels?

Butyl rubber excels in temperature performance with a stable range from -50degC to 120degC, making it ideal for applications requiring excellent resistance to heat and cold. Buna-N rubber, also known as nitrile rubber, operates effectively between -40degC and 108degC, offering good oil and fuel resistance but slightly less thermal stability than butyl. For extreme temperature environments, butyl rubber provides superior durability and resilience, outperforming Buna-N in sustained high and low temperature conditions.

Applications of Butyl Rubber vs Buna-N Rubber

Butyl rubber excels in applications requiring superior impermeability to gases, such as inner linings of tires, pharmaceutical stoppers, and bladder balloons, due to its excellent air and moisture resistance. Buna-N rubber, or nitrile rubber, is widely used in industries needing robust oil, fuel, and chemical resistance, including automotive fuel hoses, gaskets, seals, and industrial gloves. The distinct chemical resistance profiles make butyl rubber ideal for sealing applications exposed to weather and moisture, while Buna-N dominates in environments with hydrocarbons and oils.

Durability and Longevity Analysis

Butyl rubber exhibits superior resistance to weathering, ozone, and chemical exposure, contributing to its enhanced durability and extended service life compared to Buna-N rubber. Buna-N, known for its excellent oil and fuel resistance, has moderate aging properties but tends to degrade faster under prolonged heat and environmental stress. In applications requiring long-term reliability and resistance to harsh weather conditions, butyl rubber outperforms Buna-N, ensuring greater longevity and reduced maintenance.

Cost Differences: Butyl Rubber vs Buna-N Rubber

Butyl rubber generally presents a higher cost compared to Buna-N rubber due to its superior impermeability and resistance to gases and chemicals, making it ideal for applications such as inner tubes and sealants. Buna-N rubber, also known as nitrile rubber, offers a more economical option with excellent oil and fuel resistance, widely used in automotive and industrial seals. The price difference is influenced by raw material composition and performance characteristics, with Buna-N often preferred for budget-sensitive projects requiring moderate chemical resistance.

Environmental Resistance and Weatherability

Butyl rubber exhibits superior resistance to ozone, UV radiation, and extreme weather conditions, making it ideal for outdoor applications requiring long-term durability. Buna-N rubber, while offering excellent resistance to oils and fuels, has limited performance against ozone and weather exposure, leading to faster degradation under such conditions. Environmental resistance metrics consistently rank butyl rubber higher for applications demanding weatherability and exposure to harsh environments.

Ease of Manufacturing and Processing

Butyl rubber offers superior ease of manufacturing and processing due to its good extrusion and molding capabilities, making it ideal for airtight applications such as inner tubes and sealants. Buna-N (Nitrile) rubber requires precise temperature control during vulcanization and exhibits more complex processing parameters because of its sensitivity to filler dispersion and cure rates. The choice between butyl and Buna-N rubber depends largely on production efficiency and the specific mechanical properties required for the final product.

Choosing the Right Rubber: Butyl or Buna-N?

Butyl rubber offers superior impermeability to gases and excellent chemical resistance, making it ideal for applications like inner tubes and sealants. Buna-N rubber, known for its outstanding oil and fuel resistance as well as strong mechanical properties, is commonly used in automotive and industrial seals. Selecting the right rubber depends on the environmental exposure and performance requirements, with butyl favored for airtight seals and Buna-N preferred for oil-contact environments.

Butyl Rubber vs Buna-N Rubber Infographic

materialdif.com

materialdif.com