Viton offers superior chemical resistance and high-temperature stability, making it ideal for automotive and aerospace applications. EPDM excels in weather, ozone, and water resistance, preferred for outdoor seals and roofing membranes. Selecting between Viton and EPDM depends on specific environmental exposure and performance requirements.

Table of Comparison

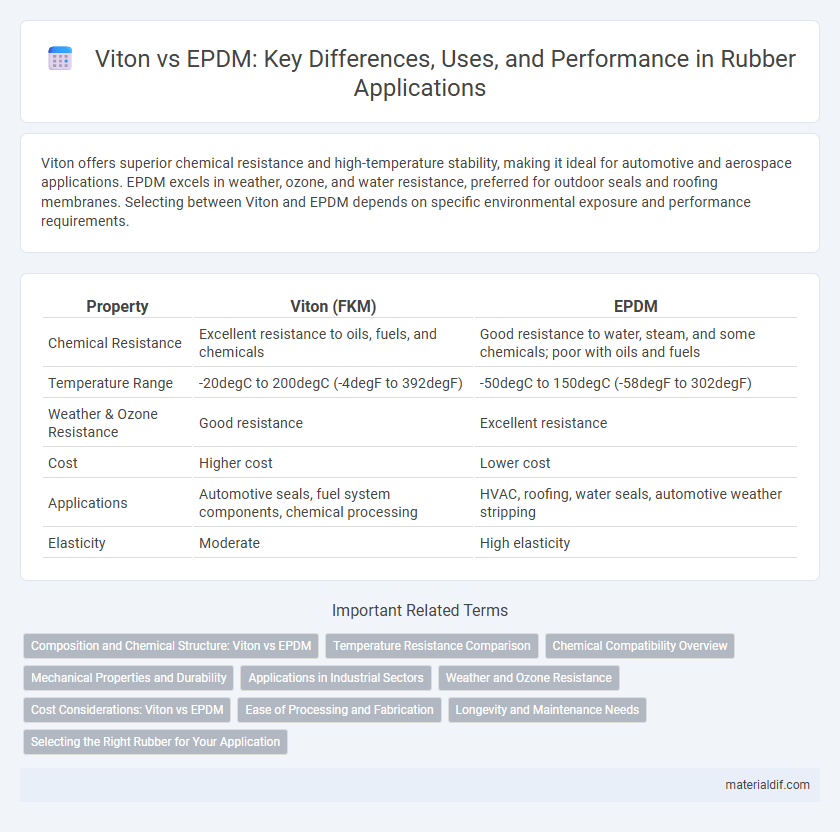

| Property | Viton (FKM) | EPDM |

|---|---|---|

| Chemical Resistance | Excellent resistance to oils, fuels, and chemicals | Good resistance to water, steam, and some chemicals; poor with oils and fuels |

| Temperature Range | -20degC to 200degC (-4degF to 392degF) | -50degC to 150degC (-58degF to 302degF) |

| Weather & Ozone Resistance | Good resistance | Excellent resistance |

| Cost | Higher cost | Lower cost |

| Applications | Automotive seals, fuel system components, chemical processing | HVAC, roofing, water seals, automotive weather stripping |

| Elasticity | Moderate | High elasticity |

Composition and Chemical Structure: Viton vs EPDM

Viton is a fluoropolymer elastomer primarily composed of vinylidene fluoride and hexafluoropropylene, featuring a carbon-fluorine bond that provides exceptional chemical resistance and thermal stability. EPDM consists of ethylene, propylene, and a diene comonomer, forming a saturated hydrocarbon backbone with unsaturated sites for vulcanization, offering excellent resistance to weathering, ozone, and polar substances. The distinct chemical structures result in Viton's superior performance against fuels and oils, whereas EPDM excels in applications requiring resistance to water, steam, and alkaline environments.

Temperature Resistance Comparison

Viton rubber offers superior temperature resistance, maintaining stability in continuous temperatures up to 200degC and short-term exposure as high as 250degC, making it ideal for harsh industrial applications. EPDM rubber operates effectively within a temperature range of -50degC to 150degC, but begins to degrade when exposed to temperatures exceeding 150degC. Choosing Viton over EPDM ensures enhanced performance in high-heat environments and greater longevity in seals, gaskets, and hoses subjected to extreme thermal conditions.

Chemical Compatibility Overview

Viton exhibits superior chemical resistance against fuels, oils, acids, and solvents, making it ideal for harsh industrial environments and automotive applications. EPDM provides excellent resistance to water, steam, and polar chemicals such as ketones and alcohols but degrades when exposed to oils and hydrocarbons. Selecting between Viton and EPDM depends on the operating environment, with Viton preferred for hydrocarbon exposure and EPDM favored for weathering and aqueous applications.

Mechanical Properties and Durability

Viton rubber exhibits superior mechanical properties such as high tensile strength, excellent compression set resistance, and remarkable temperature stability up to 200degC, making it ideal for demanding applications. EPDM offers outstanding durability with excellent weathering, ozone resistance, and flexibility at low temperatures, but its mechanical strength and chemical resistance fall short compared to Viton. The choice between Viton and EPDM depends on the specific mechanical requirements and environmental exposure, with Viton favored for chemical and thermal resilience, while EPDM excels in outdoor and weatherproof uses.

Applications in Industrial Sectors

Viton rubber excels in chemical resistance and high-temperature durability, making it ideal for automotive fuel systems, aerospace seals, and chemical processing plants. EPDM rubber demonstrates superior resistance to weather, ozone, and steam, commonly utilized in HVAC systems, water treatment facilities, and electrical insulation. Industrial sectors requiring exposure to harsh chemicals and extreme temperatures prefer Viton, while those needing weatherproofing and steam resistance opt for EPDM.

Weather and Ozone Resistance

Viton exhibits exceptional weather and ozone resistance due to its fluorocarbon composition, making it ideal for harsh environments with extreme temperatures and exposure to UV radiation. EPDM offers excellent resistance to ozone and weathering, particularly against ozone cracking, but performs better in moderate temperature ranges compared to Viton. Selecting between Viton and EPDM hinges on specific exposure conditions, with Viton preferred for high-temperature and chemically aggressive settings, while EPDM excels in outdoor applications requiring superior ozone durability.

Cost Considerations: Viton vs EPDM

Viton typically incurs higher costs due to its superior chemical resistance and temperature tolerance compared to EPDM, which offers a more budget-friendly solution for general-purpose sealing and weatherproofing. EPDM is favored for applications requiring excellent UV and ozone resistance at a lower price point, making it cost-effective for outdoor use. When selecting between Viton and EPDM, evaluating the specific operating environment and budget constraints ensures optimal balance between performance and expenditure.

Ease of Processing and Fabrication

Viton rubber, a fluorocarbon elastomer, offers excellent chemical resistance but presents challenges in ease of processing due to its higher curing temperatures and specialized equipment requirements compared to EPDM. EPDM rubber is known for its straightforward fabrication, featuring lower curing temperatures and compatibility with standard mixing and molding techniques, making it more user-friendly for mass production. The processing advantages of EPDM translate into faster cycle times and reduced manufacturing costs, while Viton demands precise control to achieve optimal material properties and durability.

Longevity and Maintenance Needs

Viton rubber offers superior longevity due to its exceptional resistance to heat, chemicals, and weathering, maintaining performance in harsh environments for over 20 years. EPDM rubber, while less durable under chemical exposure, excels in UV and ozone resistance, requiring less frequent maintenance in outdoor applications. Choosing Viton reduces replacement frequency and maintenance costs in aggressive chemical settings, whereas EPDM is ideal for cost-effective, low-maintenance solutions in milder environments.

Selecting the Right Rubber for Your Application

Selecting the right rubber for your application depends on chemical resistance, temperature tolerance, and environmental exposure. Viton offers excellent resistance to fuels, oils, and high temperatures up to 204degC, making it ideal for automotive and aerospace seals. EPDM excels in weather, ozone, and steam resistance with temperature capabilities up to 150degC, suitable for outdoor and HVAC applications.

Viton vs EPDM Infographic

materialdif.com

materialdif.com