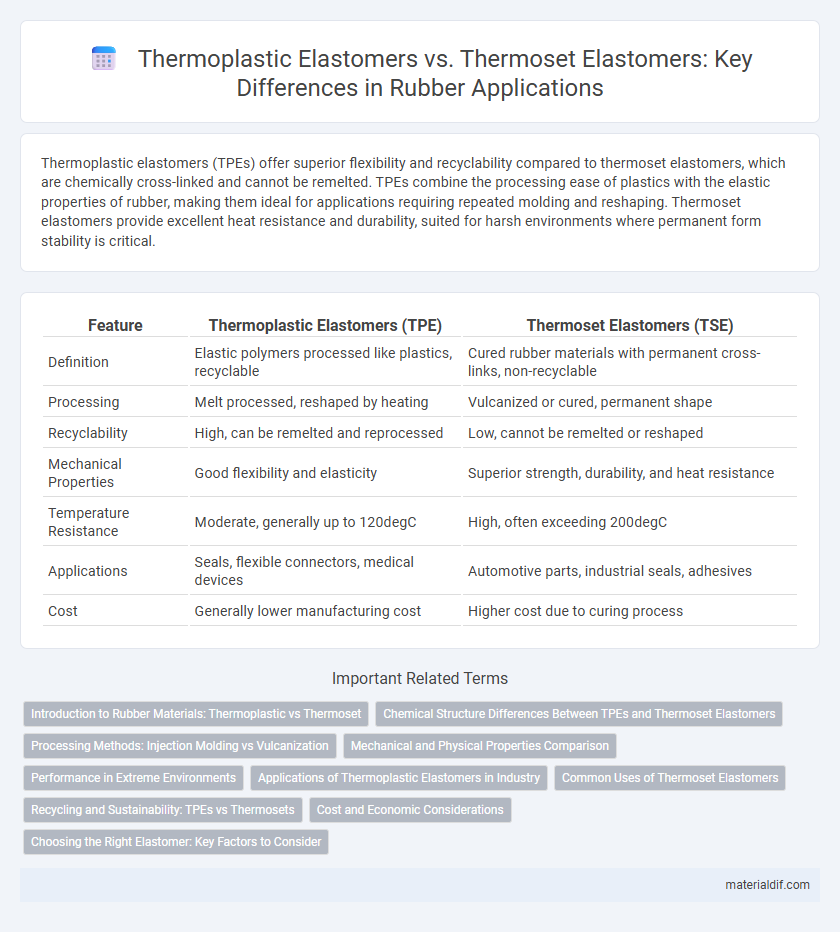

Thermoplastic elastomers (TPEs) offer superior flexibility and recyclability compared to thermoset elastomers, which are chemically cross-linked and cannot be remelted. TPEs combine the processing ease of plastics with the elastic properties of rubber, making them ideal for applications requiring repeated molding and reshaping. Thermoset elastomers provide excellent heat resistance and durability, suited for harsh environments where permanent form stability is critical.

Table of Comparison

| Feature | Thermoplastic Elastomers (TPE) | Thermoset Elastomers (TSE) |

|---|---|---|

| Definition | Elastic polymers processed like plastics, recyclable | Cured rubber materials with permanent cross-links, non-recyclable |

| Processing | Melt processed, reshaped by heating | Vulcanized or cured, permanent shape |

| Recyclability | High, can be remelted and reprocessed | Low, cannot be remelted or reshaped |

| Mechanical Properties | Good flexibility and elasticity | Superior strength, durability, and heat resistance |

| Temperature Resistance | Moderate, generally up to 120degC | High, often exceeding 200degC |

| Applications | Seals, flexible connectors, medical devices | Automotive parts, industrial seals, adhesives |

| Cost | Generally lower manufacturing cost | Higher cost due to curing process |

Introduction to Rubber Materials: Thermoplastic vs Thermoset

Thermoplastic elastomers (TPEs) combine the flexible properties of rubber with the recyclability of plastics, softening when heated and hardening upon cooling without chemical change. Thermoset elastomers undergo a curing process that creates permanent cross-links, resulting in a durable, heat-resistant material that cannot be remelted. Understanding these differences is crucial in selecting rubber materials for applications requiring either recyclability and flexibility or thermal stability and structural integrity.

Chemical Structure Differences Between TPEs and Thermoset Elastomers

Thermoplastic elastomers (TPEs) consist of linear or branched polymer chains that can be melted and reshaped due to their physical crosslinks, whereas thermoset elastomers have a chemically crosslinked, three-dimensional network structure that is permanent and cannot be remelted. The chemical structure of TPEs involves block copolymers with alternating soft and hard segments allowing elasticity combined with thermoplastic behavior. Thermoset elastomers, such as vulcanized rubber, feature covalent crosslinks formed during curing that provide superior chemical and thermal resistance but limit reprocessability.

Processing Methods: Injection Molding vs Vulcanization

Thermoplastic elastomers (TPEs) are processed using injection molding, allowing for fast cycle times, easy recyclability, and the ability to remelt and reshape multiple times. In contrast, thermoset elastomers require vulcanization, a chemical curing process that creates irreversible cross-links, resulting in enhanced heat and chemical resistance but longer production cycles. Injection molding of TPEs offers cost-effective manufacturing with less waste, whereas vulcanization of thermoset elastomers provides superior mechanical properties and dimensional stability for demanding applications.

Mechanical and Physical Properties Comparison

Thermoplastic elastomers (TPEs) exhibit higher flexibility and impact resistance due to their ability to be reshaped through heating, while thermoset elastomers (TSEs) offer superior thermal stability and chemical resistance because of their cross-linked polymer networks. TPEs generally provide better elongation at break and easier processing, whereas TSEs deliver enhanced tensile strength, hardness, and dimensional stability under extreme conditions. The choice between TPE and TSE depends on application-specific mechanical demands, including required elasticity, durability, and temperature resilience.

Performance in Extreme Environments

Thermoplastic elastomers (TPEs) exhibit superior flexibility and impact resistance in extreme temperatures, maintaining performance from -50degC to 150degC, making them ideal for applications requiring repeated thermal cycling. Thermoset elastomers, like vulcanized rubber, provide excellent chemical resistance and structural stability at higher temperatures exceeding 200degC but may become brittle under extreme cold. The choice between TPEs and thermoset elastomers depends on specific environmental stressors such as UV exposure, temperature extremes, and mechanical wear.

Applications of Thermoplastic Elastomers in Industry

Thermoplastic elastomers (TPEs) offer significant advantages in industries such as automotive, consumer goods, and medical devices due to their flexibility, recyclability, and ease of processing. Applications include flexible tubing, seals, gaskets, and soft-touch grips where durability and elasticity are crucial. Their ability to be repeatedly melted and reshaped makes TPEs ideal for manufacturing processes requiring rapid production and material efficiency.

Common Uses of Thermoset Elastomers

Thermoset elastomers are commonly used in automotive parts such as seals, gaskets, and vibration dampers due to their excellent heat resistance and durability. They also find applications in electrical insulation components and industrial machinery where chemical resistance and mechanical strength are critical. Their irreversible curing process creates a rigid molecular structure ideal for high-performance rubber products in harsh environments.

Recycling and Sustainability: TPEs vs Thermosets

Thermoplastic elastomers (TPEs) offer superior recycling potential compared to thermoset elastomers due to their reversible melting and reshaping capabilities, enabling repeated reuse without significant degradation. Thermoset elastomers, once cured, form irreversible crosslinked networks that prevent remelting, resulting in limited recycling options and increased environmental impact. The recyclability of TPEs leads to reduced material waste and enhanced sustainability in rubber applications, aligning with circular economy goals.

Cost and Economic Considerations

Thermoplastic elastomers (TPEs) generally offer lower manufacturing costs due to their recyclability and faster processing times compared to thermoset elastomers, which require energy-intensive curing processes. Despite higher upfront expenses, thermoset elastomers provide enhanced durability and heat resistance, often resulting in lower long-term maintenance costs for critical applications. Cost-efficiency analysis depends on production volume, with TPEs favored for mass production owing to reduced waste and simplified tooling.

Choosing the Right Elastomer: Key Factors to Consider

Choosing the right elastomer involves evaluating factors such as flexibility, temperature resistance, and chemical stability, where thermoplastic elastomers (TPEs) offer recyclable properties and easier processing compared to thermoset elastomers. Thermoset elastomers provide superior heat resistance and structural integrity due to their cross-linked polymer networks, making them ideal for applications requiring durability under extreme conditions. Cost-effectiveness, mechanical performance, and end-use environment compatibility are essential criteria when selecting between TPEs and thermoset elastomers for specific industrial needs.

Thermoplastic Elastomers vs Thermoset Elastomers Infographic

materialdif.com

materialdif.com