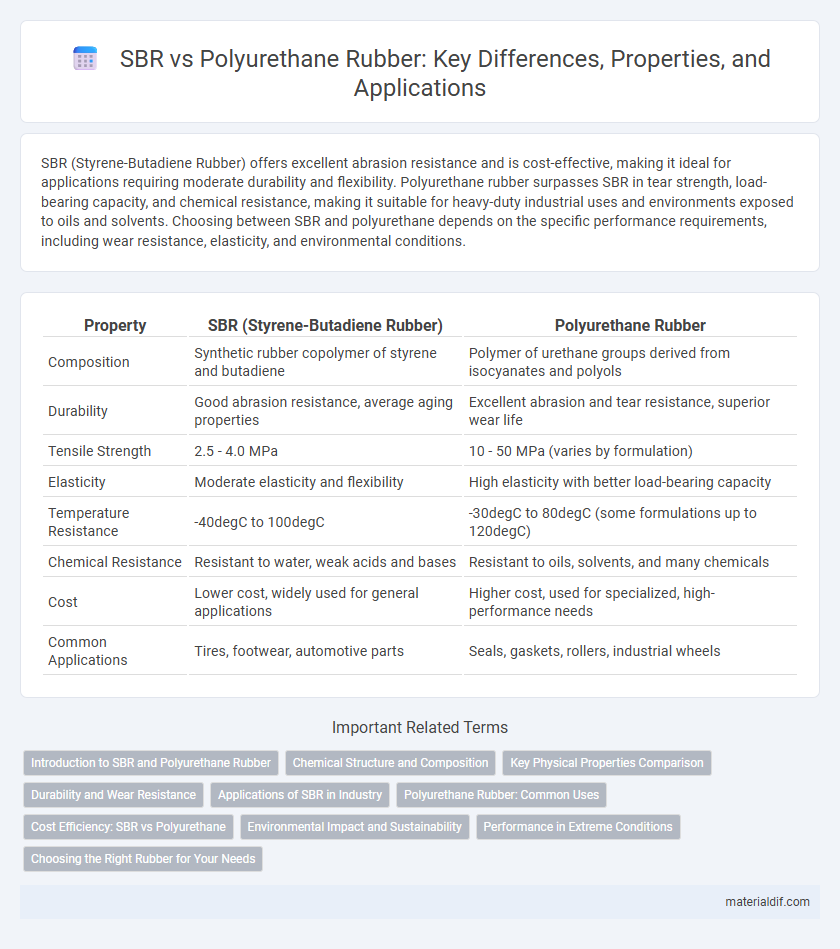

SBR (Styrene-Butadiene Rubber) offers excellent abrasion resistance and is cost-effective, making it ideal for applications requiring moderate durability and flexibility. Polyurethane rubber surpasses SBR in tear strength, load-bearing capacity, and chemical resistance, making it suitable for heavy-duty industrial uses and environments exposed to oils and solvents. Choosing between SBR and polyurethane depends on the specific performance requirements, including wear resistance, elasticity, and environmental conditions.

Table of Comparison

| Property | SBR (Styrene-Butadiene Rubber) | Polyurethane Rubber |

|---|---|---|

| Composition | Synthetic rubber copolymer of styrene and butadiene | Polymer of urethane groups derived from isocyanates and polyols |

| Durability | Good abrasion resistance, average aging properties | Excellent abrasion and tear resistance, superior wear life |

| Tensile Strength | 2.5 - 4.0 MPa | 10 - 50 MPa (varies by formulation) |

| Elasticity | Moderate elasticity and flexibility | High elasticity with better load-bearing capacity |

| Temperature Resistance | -40degC to 100degC | -30degC to 80degC (some formulations up to 120degC) |

| Chemical Resistance | Resistant to water, weak acids and bases | Resistant to oils, solvents, and many chemicals |

| Cost | Lower cost, widely used for general applications | Higher cost, used for specialized, high-performance needs |

| Common Applications | Tires, footwear, automotive parts | Seals, gaskets, rollers, industrial wheels |

Introduction to SBR and Polyurethane Rubber

Styrene-Butadiene Rubber (SBR) is a synthetic rubber known for its excellent abrasion resistance, aging stability, and cost-effectiveness, making it a popular choice for automotive tires and industrial products. Polyurethane rubber offers superior mechanical strength, elasticity, and resistance to oil, solvents, and abrasion, often used in applications requiring durability such as seals, gaskets, and wheels. Both materials serve diverse industrial purposes but differ significantly in chemical structure and performance characteristics.

Chemical Structure and Composition

Styrene-Butadiene Rubber (SBR) consists primarily of styrene and butadiene monomers arranged in a copolymer chain, providing elasticity and abrasion resistance due to its saturated hydrocarbon backbone. Polyurethane rubber is composed of urethane linkages formed by the reaction between polyols and diisocyanates, resulting in a segmented block copolymer with alternating soft and hard segments that deliver superior mechanical strength and chemical resistance. The chemical structure of SBR offers flexibility and resilience, while polyurethane's composition enables enhanced durability and resistance to oils, solvents, and abrasion.

Key Physical Properties Comparison

SBR (Styrene-Butadiene Rubber) exhibits excellent abrasion resistance and good aging stability, making it ideal for tire manufacturing and conveyor belts. Polyurethane rubber offers superior tensile strength, elasticity, and resistance to oil and chemicals, commonly used in industrial seals and rollers. While SBR provides cost-effective durability, polyurethane rubber outperforms in wear resistance and load-bearing applications due to its higher hardness and tear strength.

Durability and Wear Resistance

SBR rubber offers moderate durability and wear resistance, making it suitable for general-purpose applications with low to medium abrasion levels. Polyurethane rubber excels in wear resistance and durability, outperforming SBR by providing superior resistance to abrasion, cuts, and tears in demanding industrial environments. Polyurethane's enhanced mechanical properties contribute to longer service life and reduced maintenance costs in heavy-duty applications.

Applications of SBR in Industry

Styrene-Butadiene Rubber (SBR) is extensively utilized in the automotive industry for manufacturing tires due to its excellent abrasion resistance and aging stability. SBR also finds significant applications in conveyor belts, gaskets, and footwear soles, where durability and flexibility are essential. Its compatibility with various fillers and ease of processing make SBR a preferred choice in industrial seals and hoses.

Polyurethane Rubber: Common Uses

Polyurethane rubber is extensively used in applications requiring high abrasion resistance, durability, and flexibility, such as automotive parts, industrial rollers, and seals. Its superior tear strength and resilience make it ideal for manufacturing wheels, gaskets, and vibration dampening components. Compared to SBR, polyurethane rubber excels in environments demanding prolonged wear and chemical resistance.

Cost Efficiency: SBR vs Polyurethane

SBR (Styrene-Butadiene Rubber) offers superior cost efficiency compared to polyurethane rubber due to its lower raw material and production expenses, making it ideal for high-volume applications. Polyurethane rubber, while more expensive, provides enhanced durability and abrasion resistance that can reduce long-term maintenance and replacement costs in specific industrial settings. Evaluating total lifecycle costs reveals that SBR is preferable for budget-sensitive projects, whereas polyurethane rubber suits applications prioritizing performance and longevity.

Environmental Impact and Sustainability

SBR (Styrene Butadiene Rubber) has a significant environmental footprint due to its reliance on non-renewable petroleum resources and challenges in biodegradability, resulting in long-term waste accumulation. Polyurethane rubber offers improved sustainability through its potential for recycling and lower volatile organic compound (VOC) emissions during production, enhancing environmental performance. Both materials require advances in manufacturing and disposal methods to reduce ecological impact and promote circular economy principles in rubber applications.

Performance in Extreme Conditions

SBR (Styrene-Butadiene Rubber) offers excellent abrasion resistance and stability in dry conditions but loses flexibility and deteriorates rapidly in extreme temperatures below -40degC or above 70degC. Polyurethane rubber demonstrates superior performance under extreme conditions, maintaining elasticity and mechanical strength in a wider temperature range from -50degC to 120degC, along with enhanced resistance to oil, chemicals, and abrasion. This makes polyurethane rubber the preferred material for applications requiring durability in harsh environments and exposure to aggressive substances.

Choosing the Right Rubber for Your Needs

SBR (Styrene-Butadiene Rubber) offers excellent abrasion resistance and cost-effectiveness, making it ideal for automotive tires and industrial applications requiring durability. Polyurethane rubber provides superior elasticity, tear resistance, and chemical stability, excelling in applications like seals, gaskets, and heavy-duty rollers. Selecting the right rubber depends on balancing mechanical properties, environmental exposure, and budget constraints to optimize performance and longevity.

SBR vs Polyurethane Rubber Infographic

materialdif.com

materialdif.com