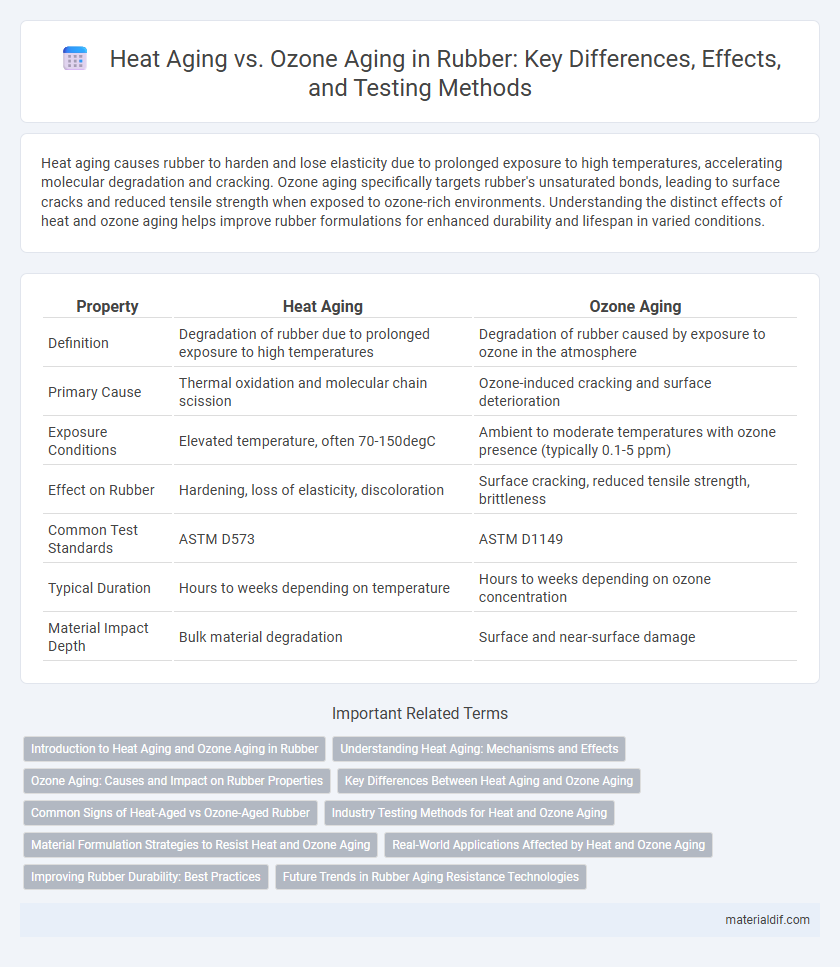

Heat aging causes rubber to harden and lose elasticity due to prolonged exposure to high temperatures, accelerating molecular degradation and cracking. Ozone aging specifically targets rubber's unsaturated bonds, leading to surface cracks and reduced tensile strength when exposed to ozone-rich environments. Understanding the distinct effects of heat and ozone aging helps improve rubber formulations for enhanced durability and lifespan in varied conditions.

Table of Comparison

| Property | Heat Aging | Ozone Aging |

|---|---|---|

| Definition | Degradation of rubber due to prolonged exposure to high temperatures | Degradation of rubber caused by exposure to ozone in the atmosphere |

| Primary Cause | Thermal oxidation and molecular chain scission | Ozone-induced cracking and surface deterioration |

| Exposure Conditions | Elevated temperature, often 70-150degC | Ambient to moderate temperatures with ozone presence (typically 0.1-5 ppm) |

| Effect on Rubber | Hardening, loss of elasticity, discoloration | Surface cracking, reduced tensile strength, brittleness |

| Common Test Standards | ASTM D573 | ASTM D1149 |

| Typical Duration | Hours to weeks depending on temperature | Hours to weeks depending on ozone concentration |

| Material Impact Depth | Bulk material degradation | Surface and near-surface damage |

Introduction to Heat Aging and Ozone Aging in Rubber

Heat aging in rubber involves prolonged exposure to elevated temperatures, causing molecular chain scission and cross-linking that degrade mechanical properties such as elasticity and tensile strength. Ozone aging specifically targets rubber's unsaturated carbon-carbon bonds, leading to surface cracking and reduced durability when exposed to atmospheric ozone, even at low concentrations. Understanding these aging mechanisms is crucial for enhancing rubber formulations to improve resistance against thermal degradation and ozone-induced deterioration.

Understanding Heat Aging: Mechanisms and Effects

Heat aging in rubber involves oxidation and thermal degradation processes that alter molecular chains, leading to changes in elasticity, tensile strength, and overall durability. Elevated temperatures accelerate free radical reactions, causing chain scission or cross-linking, which ultimately impacts the rubber's mechanical properties. Understanding the specific temperature thresholds and exposure durations is crucial for predicting performance and lifespan in heat-intensive applications.

Ozone Aging: Causes and Impact on Rubber Properties

Ozone aging in rubber is primarily caused by exposure to ozone molecules in the atmosphere, which attack the double bonds in unsaturated rubber polymers, leading to chain scission and surface cracking. This degradation significantly reduces tensile strength, elongation at break, and overall elasticity, impairing the durability and mechanical performance of rubber products. Ozone-resistant rubbers, such as EPDM and silicone, are specifically formulated to withstand these oxidative effects and maintain longevity in harsh environmental conditions.

Key Differences Between Heat Aging and Ozone Aging

Heat aging primarily degrades rubber through thermal oxidation, causing hardening, loss of elasticity, and cracking at elevated temperatures over time. Ozone aging specifically targets rubber surfaces exposed to atmospheric ozone, resulting in surface cracking and embrittlement due to ozone molecules attacking unsaturated rubber bonds. The key differences lie in the mechanisms of degradation--thermal oxidation versus ozone-induced surface oxidation--and the environmental conditions required for each aging process.

Common Signs of Heat-Aged vs Ozone-Aged Rubber

Heat-aged rubber typically shows hardening, loss of elasticity, and surface cracking due to prolonged exposure to elevated temperatures, while ozone-aged rubber exhibits fine, surface cracks aligned perpendicular to tensile stress, known as ozone cracking. Heat aging accelerates oxidative degradation leading to embrittlement, whereas ozone aging primarily causes superficial cracking without significant loss of mass. Common signs of heat-aged rubber include discoloration and brittleness, whereas ozone-aged rubber often presents with visible cracks without substantial color change.

Industry Testing Methods for Heat and Ozone Aging

Industry testing methods for heat aging in rubber primarily involve exposing samples to elevated temperatures, typically ranging from 70degC to 150degC, for extended periods to assess changes in mechanical properties such as tensile strength and elongation. Ozone aging tests simulate exposure to ozone concentrations of 50 to 100 parts per hundred million (pphm) at ambient or controlled conditions, focusing on surface crack formation and material degradation. Standardized protocols like ASTM D573 for heat aging and ASTM D1149 for ozone aging enable consistent evaluation of rubber durability in industrial applications.

Material Formulation Strategies to Resist Heat and Ozone Aging

Material formulation strategies to resist heat and ozone aging in rubber focus on incorporating antioxidants such as phenolic and amine-based stabilizers to prevent oxidative degradation during heat exposure. Anti-ozonants like waxes and substituted p-phenylenediamines (PPDs) form protective barriers on the rubber surface, reducing ozone attack and cracking. Optimizing polymer blends with halogenated rubbers or incorporating fillers like carbon black also enhances durability against both heat and ozone aging by improving structural integrity.

Real-World Applications Affected by Heat and Ozone Aging

Heat aging in rubber commonly leads to hardening and loss of elasticity, significantly impacting automotive tires and seals exposed to high temperatures. Ozone aging causes surface cracks and degradation, particularly affecting outdoor rubber components such as conveyor belts and weather-exposed gaskets. Industries like aerospace and construction must account for both heat and ozone aging to ensure durability and safety in real-world applications.

Improving Rubber Durability: Best Practices

Heat aging accelerates the molecular degradation of rubber, causing loss of elasticity and increased brittleness, while ozone aging targets double bonds in rubber molecules, leading to surface cracking. Improving rubber durability requires selecting antioxidants and antiozonants tailored to specific aging mechanisms, such as using hindered phenols for heat resistance and waxes or polymers for ozone protection. Regular testing under controlled environmental conditions and optimizing formulation with synergistic stabilizers ensure enhanced longevity and performance of rubber products.

Future Trends in Rubber Aging Resistance Technologies

Emerging innovations in rubber aging resistance focus on enhancing both heat aging and ozone aging durability by incorporating advanced antioxidants and ozone-resistant polymers such as EPDM and FKM. Nanotechnology additives like graphene and carbon nanotubes are being developed to improve thermal stability and ozone resistance at the molecular level, extending the service life of rubber components. Research emphasizes sustainable, environment-friendly compounds that provide superior protection against oxidative degradation while meeting stringent regulatory standards for industrial and automotive applications.

Heat Aging vs Ozone Aging Infographic

materialdif.com

materialdif.com