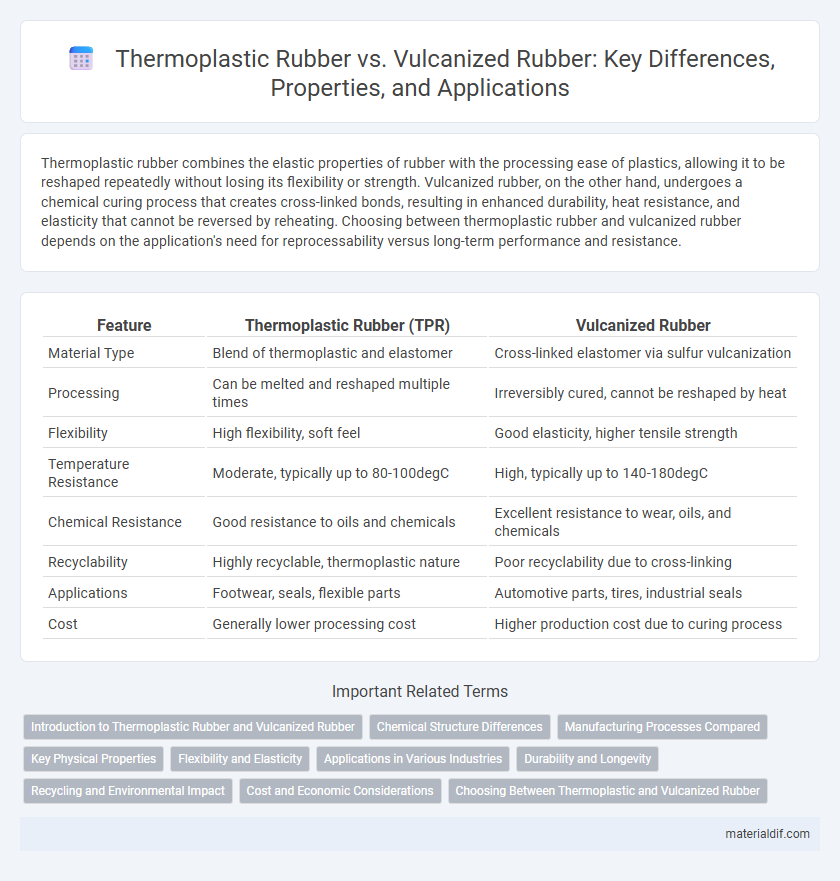

Thermoplastic rubber combines the elastic properties of rubber with the processing ease of plastics, allowing it to be reshaped repeatedly without losing its flexibility or strength. Vulcanized rubber, on the other hand, undergoes a chemical curing process that creates cross-linked bonds, resulting in enhanced durability, heat resistance, and elasticity that cannot be reversed by reheating. Choosing between thermoplastic rubber and vulcanized rubber depends on the application's need for reprocessability versus long-term performance and resistance.

Table of Comparison

| Feature | Thermoplastic Rubber (TPR) | Vulcanized Rubber |

|---|---|---|

| Material Type | Blend of thermoplastic and elastomer | Cross-linked elastomer via sulfur vulcanization |

| Processing | Can be melted and reshaped multiple times | Irreversibly cured, cannot be reshaped by heat |

| Flexibility | High flexibility, soft feel | Good elasticity, higher tensile strength |

| Temperature Resistance | Moderate, typically up to 80-100degC | High, typically up to 140-180degC |

| Chemical Resistance | Good resistance to oils and chemicals | Excellent resistance to wear, oils, and chemicals |

| Recyclability | Highly recyclable, thermoplastic nature | Poor recyclability due to cross-linking |

| Applications | Footwear, seals, flexible parts | Automotive parts, tires, industrial seals |

| Cost | Generally lower processing cost | Higher production cost due to curing process |

Introduction to Thermoplastic Rubber and Vulcanized Rubber

Thermoplastic rubber (TPR) combines the properties of rubber with the processability of plastics, allowing it to be melted and reshaped multiple times without losing elasticity. Vulcanized rubber undergoes a chemical cross-linking process using sulfur, resulting in a durable, heat-resistant, and elastic material that cannot be remelted. These fundamental differences in production and properties determine their distinct applications in automotive, footwear, and industrial products.

Chemical Structure Differences

Thermoplastic rubber (TPR) consists of linear or branched polymers that lack chemical cross-links, allowing it to soften when heated and harden upon cooling. Vulcanized rubber contains sulfur-induced cross-links between polymer chains, creating a three-dimensional network that enhances elasticity, durability, and resistance to deformation. These chemical structure differences result in TPR being recyclable and moldable, while vulcanized rubber offers superior mechanical strength and thermal stability.

Manufacturing Processes Compared

Thermoplastic rubber (TPR) is produced via processes like injection molding and extrusion, allowing for re-melting and reshaping without chemical changes. In contrast, vulcanized rubber undergoes a chemical cross-linking process involving sulfur and heat, creating irreversible bonds that enhance durability and elasticity. Manufacturing vulcanized rubber requires longer curing times and specialized molds, while thermoplastic rubber enables faster, more flexible production cycles.

Key Physical Properties

Thermoplastic rubber exhibits high flexibility and can be repeatedly melted and reshaped without losing its elastic properties, making it ideal for applications requiring recyclability and easy processing. Vulcanized rubber, formed through a chemical cross-linking process, offers superior tensile strength, abrasion resistance, and heat stability essential for demanding mechanical and automotive uses. Key physical differences include thermoplastic rubber's lower hardness and reduced resistance to oils and solvents compared to vulcanized rubber, which maintains consistent elasticity and durability under extreme conditions.

Flexibility and Elasticity

Thermoplastic rubber offers superior flexibility due to its ability to soften when heated and harden when cooled, enabling repeated reshaping without losing elasticity. Vulcanized rubber, treated with sulfur cross-linking, provides enhanced elasticity and durability, maintaining its shape under stress and high temperatures. The choice between thermoplastic and vulcanized rubber depends on the required balance of flexibility for molding and elasticity for long-term performance.

Applications in Various Industries

Thermoplastic rubber's flexibility and recyclability make it ideal for automotive interior components, medical devices, and consumer goods, where repeated molding and precise shaping are essential. Vulcanized rubber's superior durability and heat resistance suit it for heavy-duty applications like tires, industrial belts, and sealing systems in aerospace and construction industries. Both materials serve distinct roles, with thermoplastic rubber excelling in lightweight, high-precision uses and vulcanized rubber dominating in high-stress, long-lasting environments.

Durability and Longevity

Thermoplastic rubber offers excellent flexibility and ease of processing but typically exhibits lower durability and longevity compared to vulcanized rubber, which undergoes sulfur cross-linking to create a highly resilient and wear-resistant material. Vulcanized rubber withstands harsh environmental conditions, including extreme temperatures and chemical exposure, making it ideal for long-term applications requiring superior abrasion resistance and mechanical strength. The molecular cross-linking in vulcanized rubber significantly enhances its lifespan, reducing degradation over time compared to the thermoplastic variants.

Recycling and Environmental Impact

Thermoplastic rubber (TPR) offers superior recyclability compared to vulcanized rubber due to its ability to be melted and reshaped multiple times without significant degradation, reducing landfill waste and resource consumption. Vulcanized rubber, treated with sulfur to enhance durability and elasticity, is challenging to recycle because its cross-linked molecular structure resists melting and reshaping, often resulting in incineration or landfill disposal. The environmental impact of thermoplastic rubber is consequently lower, supporting circular economy practices and minimizing carbon emissions associated with rubber production and disposal.

Cost and Economic Considerations

Thermoplastic rubber (TPR) generally incurs lower production costs due to its ability to be melted and reshaped repeatedly, reducing manufacturing time and waste. Vulcanized rubber requires a more energy-intensive curing process involving sulfur cross-linking, which increases overall expenses but provides superior durability and heat resistance. For cost-sensitive applications, TPR offers economic advantages with faster processing and recyclability, while vulcanized rubber investments yield long-term value in high-performance and lifespan-critical products.

Choosing Between Thermoplastic and Vulcanized Rubber

Thermoplastic rubber offers excellent flexibility, ease of molding, and recyclability, making it ideal for applications requiring rapid prototyping and frequent reshaping. Vulcanized rubber provides superior durability, chemical resistance, and heat stability, which suits heavy-duty products like automotive tires and industrial seals. Selecting between thermoplastic and vulcanized rubber depends on the balance between manufacturing efficiency and the required mechanical performance of the final product.

Thermoplastic Rubber vs Vulcanized Rubber Infographic

materialdif.com

materialdif.com