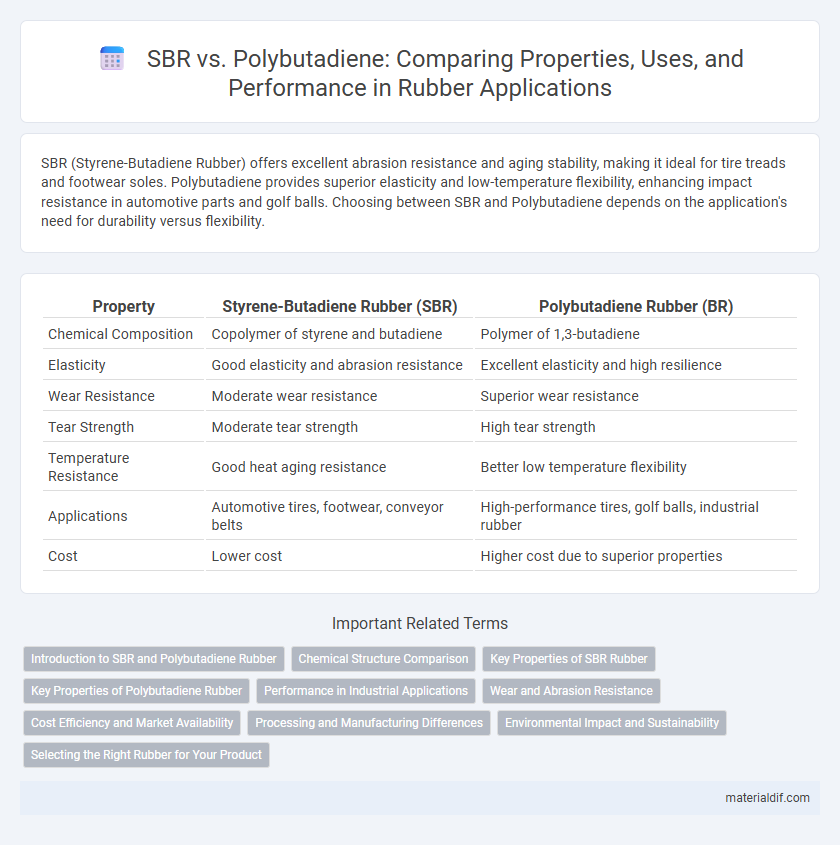

SBR (Styrene-Butadiene Rubber) offers excellent abrasion resistance and aging stability, making it ideal for tire treads and footwear soles. Polybutadiene provides superior elasticity and low-temperature flexibility, enhancing impact resistance in automotive parts and golf balls. Choosing between SBR and Polybutadiene depends on the application's need for durability versus flexibility.

Table of Comparison

| Property | Styrene-Butadiene Rubber (SBR) | Polybutadiene Rubber (BR) |

|---|---|---|

| Chemical Composition | Copolymer of styrene and butadiene | Polymer of 1,3-butadiene |

| Elasticity | Good elasticity and abrasion resistance | Excellent elasticity and high resilience |

| Wear Resistance | Moderate wear resistance | Superior wear resistance |

| Tear Strength | Moderate tear strength | High tear strength |

| Temperature Resistance | Good heat aging resistance | Better low temperature flexibility |

| Applications | Automotive tires, footwear, conveyor belts | High-performance tires, golf balls, industrial rubber |

| Cost | Lower cost | Higher cost due to superior properties |

Introduction to SBR and Polybutadiene Rubber

Styrene-Butadiene Rubber (SBR) is a synthetic rubber widely used due to its excellent abrasion resistance and aging stability, commonly found in tire manufacturing and conveyor belts. Polybutadiene rubber offers superior elasticity and low-temperature flexibility, making it ideal for high-performance tires and impact-resistant products. Both SBR and Polybutadiene are crucial in rubber compounding, with SBR emphasizing durability and Polybutadiene prioritizing resilience and toughness.

Chemical Structure Comparison

Styrene-Butadiene Rubber (SBR) consists of copolymerized styrene and butadiene units, creating a molecular chain with alternating aromatic styrene rings and unsaturated butadiene segments that impart balanced tensile strength and abrasion resistance. Polybutadiene Rubber (BR) comprises nearly 100% 1,3-butadiene monomers, resulting in a highly flexible polymer chain with predominantly cis-1,4 configuration that provides superior elasticity and low-temperature performance. The chemical structure difference between SBR's random copolymer and polybutadiene's homopolymer governs their mechanical properties and application suitability in tires, footwear, and industrial products.

Key Properties of SBR Rubber

SBR (Styrene-Butadiene Rubber) exhibits excellent abrasion resistance and aging stability, making it ideal for tire treads and automotive parts. Its superior heat resistance and good elasticity ensure durability under varying temperatures, unlike Polybutadiene, which excels in low-temperature flexibility but has lower abrasion resistance. High tensile strength and resistance to wear highlight SBR as a versatile synthetic rubber for heavy-duty industrial applications.

Key Properties of Polybutadiene Rubber

Polybutadiene rubber (BR) exhibits exceptional wear resistance and high resilience, making it ideal for applications requiring durability and flexibility under stress. It has a low glass transition temperature, which provides excellent elasticity at low temperatures compared to SBR. The superior abrasion resistance and impact strength of polybutadiene enhance tire performance and improve lifespan in industrial rubber products.

Performance in Industrial Applications

SBR (Styrene-Butadiene Rubber) exhibits superior abrasion resistance and aging stability, making it ideal for automotive tires and conveyor belts, while Polybutadiene offers exceptional low-temperature flexibility and outstanding impact resistance suitable for industrial parts and golf balls. SBR's balanced mechanical properties support versatility in applications requiring moderate strength and durability, whereas Polybutadiene's resilience under dynamic stress enhances performance in heavy-duty machinery components. The choice between SBR and Polybutadiene depends on specific industrial requirements such as wear resistance, elongation, and thermal stability.

Wear and Abrasion Resistance

Styrene-Butadiene Rubber (SBR) exhibits superior wear and abrasion resistance compared to Polybutadiene Rubber due to its higher polymer density and better interaction with fillers like carbon black. Polybutadiene Rubber offers excellent flexibility and resilience but generally shows lower abrasion resistance under harsh mechanical stress. In tire manufacturing and industrial applications, SBR is preferred for components requiring extended durability against surface wear.

Cost Efficiency and Market Availability

Styrene-Butadiene Rubber (SBR) offers superior cost efficiency due to its lower raw material and production costs compared to Polybutadiene Rubber (BR), which is generally more expensive owing to its specialized applications. SBR dominates the market availability, widely used in tire manufacturing and industrial goods, while Polybutadiene's availability is more limited and primarily targeted at high-performance tire treads and impact-resistant products. Market demand for SBR remains consistently high, driven by its balanced performance and cost-effective production, making it more accessible across various industries.

Processing and Manufacturing Differences

SBR (Styrene-Butadiene Rubber) offers easier processing due to its good compatibility with various fillers and additives, facilitating mixing and vulcanization in tire manufacturing. Polybutadiene rubber requires more precise control during processing because of its high elasticity and lower glass transition temperature, demanding specific temperature and curing conditions to avoid premature crosslinking. Manufacturing SBR typically involves emulsion or solution polymerization methods, while polybutadiene is predominantly produced via anionic polymerization to achieve desired molecular weight and microstructure for enhanced abrasion resistance.

Environmental Impact and Sustainability

SBR (Styrene-Butadiene Rubber) and Polybutadiene differ significantly in environmental impact and sustainability. SBR production involves higher energy consumption and reliance on non-renewable petrochemicals, leading to a larger carbon footprint, while Polybutadiene offers better wear resistance, reducing tire replacement frequency and resource use. Recycling efforts and advances in bio-based alternatives for both rubbers are critical to improving their environmental profiles and promoting sustainable rubber manufacturing.

Selecting the Right Rubber for Your Product

Selecting the right rubber for your product depends on performance requirements such as abrasion resistance, flexibility, and temperature tolerance. Styrene-Butadiene Rubber (SBR) offers excellent abrasion resistance and aging stability, making it ideal for automotive tires and industrial belts. Polybutadiene rubber provides superior elasticity and low-temperature flexibility, which is essential for high-performance tires and impact-resistant applications.

SBR vs Polybutadiene Infographic

materialdif.com

materialdif.com