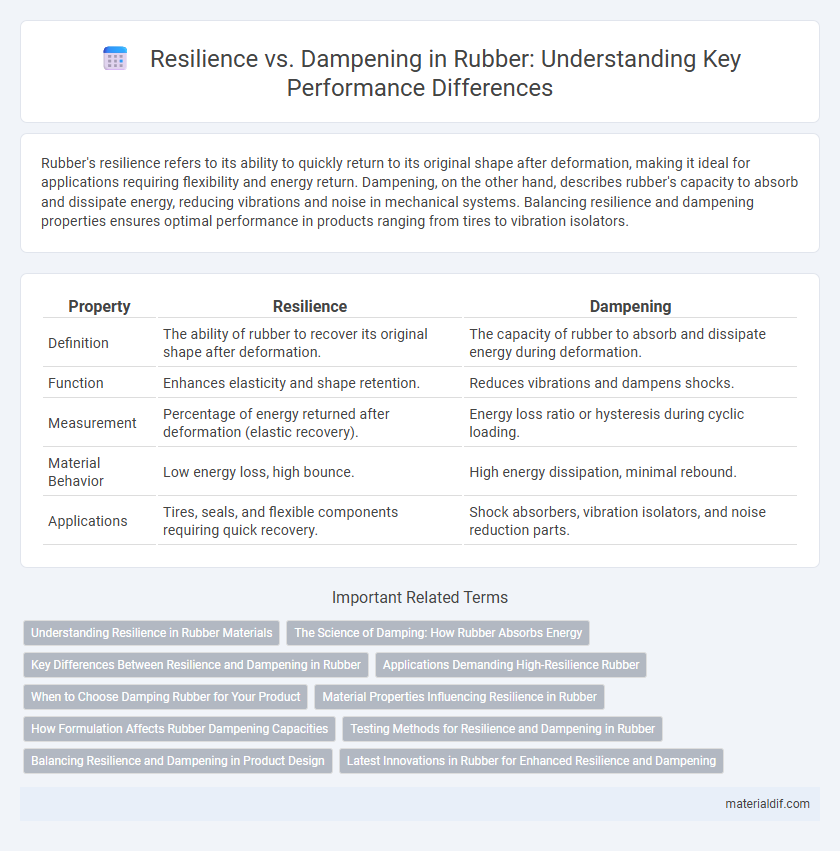

Rubber's resilience refers to its ability to quickly return to its original shape after deformation, making it ideal for applications requiring flexibility and energy return. Dampening, on the other hand, describes rubber's capacity to absorb and dissipate energy, reducing vibrations and noise in mechanical systems. Balancing resilience and dampening properties ensures optimal performance in products ranging from tires to vibration isolators.

Table of Comparison

| Property | Resilience | Dampening |

|---|---|---|

| Definition | The ability of rubber to recover its original shape after deformation. | The capacity of rubber to absorb and dissipate energy during deformation. |

| Function | Enhances elasticity and shape retention. | Reduces vibrations and dampens shocks. |

| Measurement | Percentage of energy returned after deformation (elastic recovery). | Energy loss ratio or hysteresis during cyclic loading. |

| Material Behavior | Low energy loss, high bounce. | High energy dissipation, minimal rebound. |

| Applications | Tires, seals, and flexible components requiring quick recovery. | Shock absorbers, vibration isolators, and noise reduction parts. |

Understanding Resilience in Rubber Materials

Resilience in rubber materials refers to the ability to absorb energy when deformed and release it upon unloading, directly impacting the material's performance in dynamic applications. High resilience rubber exhibits low hysteresis, minimizing energy loss as heat and enhancing durability in products like tires and vibration isolators. Understanding the balance between resilience and dampening is critical for optimizing rubber compounds to achieve desired mechanical properties and longevity.

The Science of Damping: How Rubber Absorbs Energy

Rubber's unique molecular structure allows it to absorb and dissipate energy through internal friction, converting mechanical vibrations into heat, which enhances its damping properties. The cross-linked polymer chains in rubber resist deformation and return to their original shape, providing resilience, while the viscoelastic nature facilitates energy dissipation during dynamic loading. This combination of resilience and dampening makes rubber ideal for applications requiring vibration isolation and shock absorption.

Key Differences Between Resilience and Dampening in Rubber

Resilience in rubber refers to its ability to rapidly restore shape and recover energy after deformation, making it ideal for applications requiring quick rebound and durability. Dampening describes rubber's capacity to absorb and dissipate vibrational energy as heat, reducing noise and vibration transmission in mechanical systems. Key differences lie in resilience prioritizing energy return and elasticity, whereas dampening focuses on energy absorption and vibration control.

Applications Demanding High-Resilience Rubber

High-resilience rubber is essential in applications requiring superior energy return and quick recovery, such as athletic footwear soles, vibration isolators, and impact-absorbing equipment. Its unique molecular structure enables rapid deformation and rebound, providing enhanced dynamic performance compared to conventional dampening materials. Industries like aerospace, automotive suspension systems, and sports protective gear rely on high-resilience rubber for optimal shock absorption and sustained durability under repetitive stress.

When to Choose Damping Rubber for Your Product

Damping rubber is ideal for applications requiring vibration absorption and noise reduction, such as automotive mounts and industrial machinery components. Its molecular structure converts mechanical energy into heat, effectively minimizing resonance and enhancing operational stability. Choose damping rubber when product performance depends on reducing dynamic forces and maintaining structural integrity under cyclic loading.

Material Properties Influencing Resilience in Rubber

Rubber's resilience is primarily determined by its molecular structure and cross-link density, which allow it to efficiently absorb and release energy during deformation. High resilience in rubber results from optimal polymer chain flexibility and low internal friction, enabling rapid recovery after impact. In contrast, dampening depends on energy dissipation through viscoelastic behavior, where increased fillers or plasticizers reduce resilience by converting mechanical energy into heat.

How Formulation Affects Rubber Dampening Capacities

Rubber formulation significantly influences its dampening capacities through variations in polymer type, filler content, and crosslink density, which control the material's ability to absorb and dissipate vibrational energy. High filler concentrations such as carbon black or silica increase stiffness and reduce energy loss, thus lowering dampening performance, while softer polymers with lower crosslink density enhance hysteresis and vibration isolation. Optimizing the balance between resilience and dampening requires careful selection of ingredients to tailor rubber compounds for specific vibrational environments and mechanical demands.

Testing Methods for Resilience and Dampening in Rubber

Testing methods for resilience in rubber typically involve Izod or Charpy impact tests, which measure the material's ability to absorb energy and return to its original shape after deformation. Dampening properties are often evaluated through dynamic mechanical analysis (DMA), where the material's viscoelastic response, including energy dissipation as heat, is quantified under cyclic loading. Accurate assessment of both properties is crucial for applications requiring energy absorption and vibration reduction, such as automotive components and industrial machinery mounts.

Balancing Resilience and Dampening in Product Design

Balancing resilience and dampening in rubber product design is critical for optimizing performance and durability. High resilience rubber enhances energy return and responsiveness, ideal for applications requiring quick recovery, while increased dampening reduces vibrations and noise, improving comfort and stability. Engineers must carefully select rubber compounds and physical properties to meet specific functional requirements, ensuring a precise combination of elasticity and energy absorption.

Latest Innovations in Rubber for Enhanced Resilience and Dampening

Recent innovations in rubber materials have significantly enhanced resilience and dampening properties through the development of advanced polymer blends and nanocomposite additives. Incorporating graphene oxide and silica nanoparticles into rubber matrices improves energy absorption and resistance to deformation, resulting in superior shock absorption and durability. Smart rubber formulations featuring self-healing capabilities and tunable viscoelasticity optimize performance for automotive, aerospace, and industrial vibration control applications.

Resilience vs Dampening Infographic

materialdif.com

materialdif.com