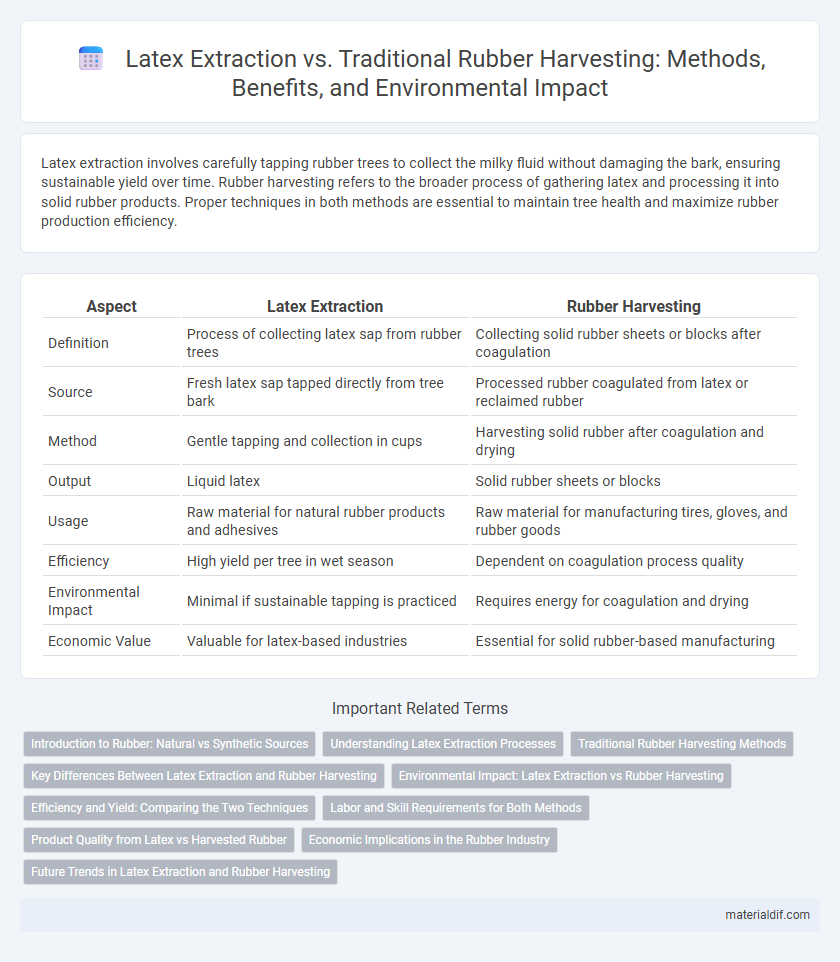

Latex extraction involves carefully tapping rubber trees to collect the milky fluid without damaging the bark, ensuring sustainable yield over time. Rubber harvesting refers to the broader process of gathering latex and processing it into solid rubber products. Proper techniques in both methods are essential to maintain tree health and maximize rubber production efficiency.

Table of Comparison

| Aspect | Latex Extraction | Rubber Harvesting |

|---|---|---|

| Definition | Process of collecting latex sap from rubber trees | Collecting solid rubber sheets or blocks after coagulation |

| Source | Fresh latex sap tapped directly from tree bark | Processed rubber coagulated from latex or reclaimed rubber |

| Method | Gentle tapping and collection in cups | Harvesting solid rubber after coagulation and drying |

| Output | Liquid latex | Solid rubber sheets or blocks |

| Usage | Raw material for natural rubber products and adhesives | Raw material for manufacturing tires, gloves, and rubber goods |

| Efficiency | High yield per tree in wet season | Dependent on coagulation process quality |

| Environmental Impact | Minimal if sustainable tapping is practiced | Requires energy for coagulation and drying |

| Economic Value | Valuable for latex-based industries | Essential for solid rubber-based manufacturing |

Introduction to Rubber: Natural vs Synthetic Sources

Latex extraction involves tapping rubber trees (Hevea brasiliensis) to collect natural rubber latex, a biodegradable polymer known for its elasticity and resilience. Rubber harvesting encompasses the broader process, including both natural rubber collection and the production of synthetic rubber derived from petrochemical sources like styrene and butadiene. Natural rubber remains essential for applications requiring superior tensile strength and flexibility, while synthetic rubber offers enhanced resistance to heat and chemicals.

Understanding Latex Extraction Processes

Latex extraction involves tapping rubber trees to collect the milky fluid before it coagulates into solid rubber, a process requiring precise incisions to maximize yield without harming the tree. Rubber harvesting, by contrast, encompasses the entire process of obtaining rubber products, including both latex collection and the subsequent coagulation, drying, and processing stages. Understanding latex extraction processes is vital for improving rubber productivity, ensuring sustainable tree health, and optimizing the quality of natural rubber produced.

Traditional Rubber Harvesting Methods

Traditional rubber harvesting methods primarily involve tapping Hevea brasiliensis trees to collect latex by making precise incisions in the bark, ensuring sustainable latex flow without damaging the tree. This manual tapping process requires skill to maintain tree health and optimize latex yield, often performed using a tapping knife during early morning hours. Unlike latex extraction in industrial settings that may use chemical stimulants or mechanical aids, traditional harvesting relies solely on natural processes and worker expertise for rubber production.

Key Differences Between Latex Extraction and Rubber Harvesting

Latex extraction involves tapping rubber trees to collect the liquid latex sap, which is the raw material for producing natural rubber. Rubber harvesting refers to the process of gathering mature rubber products, such as coagulated latex sheets or rubber blocks, after the latex has been processed. Key differences include that latex extraction is a continuous, non-destructive process focused on fluid collection, whereas rubber harvesting is a final-stage activity involving solid rubber ready for manufacturing.

Environmental Impact: Latex Extraction vs Rubber Harvesting

Latex extraction involves tapping rubber trees to collect the milky fluid without felling the tree, resulting in minimal deforestation and promoting sustainable rubber production. Rubber harvesting, which requires cutting down rubber trees for raw rubber, leads to significant habitat loss and increased carbon emissions. Prioritizing latex extraction helps maintain biodiversity and reduces the environmental footprint associated with rubber cultivation.

Efficiency and Yield: Comparing the Two Techniques

Latex extraction involves carefully tapping rubber trees to collect the milky fluid with minimal damage, maximizing yield through precision and timing. Rubber harvesting, often referring to the collection of coagulated latex or rubber sheets, requires more labor and can impact tree health if not managed properly. Efficiency in latex extraction generally surpasses traditional rubber harvesting by sustaining continuous production and optimizing raw material quality.

Labor and Skill Requirements for Both Methods

Latex extraction involves skilled tapping workers trained to make precise incisions on rubber trees, ensuring optimal sap flow without damaging the bark, which demands steady hands and experience. Rubber harvesting, particularly for solid rubber, requires labor-intensive methods such as cutting and collecting rubber sheets, which are less technically demanding but require physical strength and endurance. Efficient latex extraction increases yield quality and sustainability, while rubber harvesting emphasizes manual labor intensity and post-processing skills.

Product Quality from Latex vs Harvested Rubber

Latex extraction preserves the rubber's natural elasticity and purity, resulting in higher-quality raw material for specialized products such as gloves and adhesives. Harvested rubber sheets undergo coagulation and drying, which can introduce impurities and reduce elasticity, affecting their suitability for heavy-duty applications. Maintaining proper harvesting techniques can minimize quality degradation but generally, latex offers superior consistency in molecular structure and performance.

Economic Implications in the Rubber Industry

Latex extraction, involving the careful tapping of rubber trees, offers higher-quality raw material and steady income but requires skilled labor and sustained tree health management. Rubber harvesting, including the collection of solid rubber sheets or blocks, demands more processing but can provide bulk output suited to industrial manufacturing, influencing market pricing structures and export volumes. Economic implications hinge on balancing labor costs, yield efficiency, and product quality to optimize profitability within the global rubber supply chain.

Future Trends in Latex Extraction and Rubber Harvesting

Future trends in latex extraction emphasize sustainable methods such as precision tapping using automated sensors to optimize yield and reduce tree damage. Innovations in rubber harvesting include robotic systems and drones for monitoring plantation health, enhancing efficiency and minimizing labor costs. Advancements in biotechnology aim to develop high-yield rubber tree clones resistant to pests and climate stress, supporting increased production amid growing global demand.

Latex Extraction vs Rubber Harvesting Infographic

materialdif.com

materialdif.com