Isoprene rubber offers excellent elasticity and tensile strength, closely mimicking natural rubber's properties, making it ideal for flexible, durable applications. Chloroprene rubber provides superior resistance to oil, weathering, and chemicals, enhancing its suitability for automotive and industrial uses. Choosing between isoprene and chloroprene rubber depends on the specific performance requirements such as flexibility versus chemical resistance.

Table of Comparison

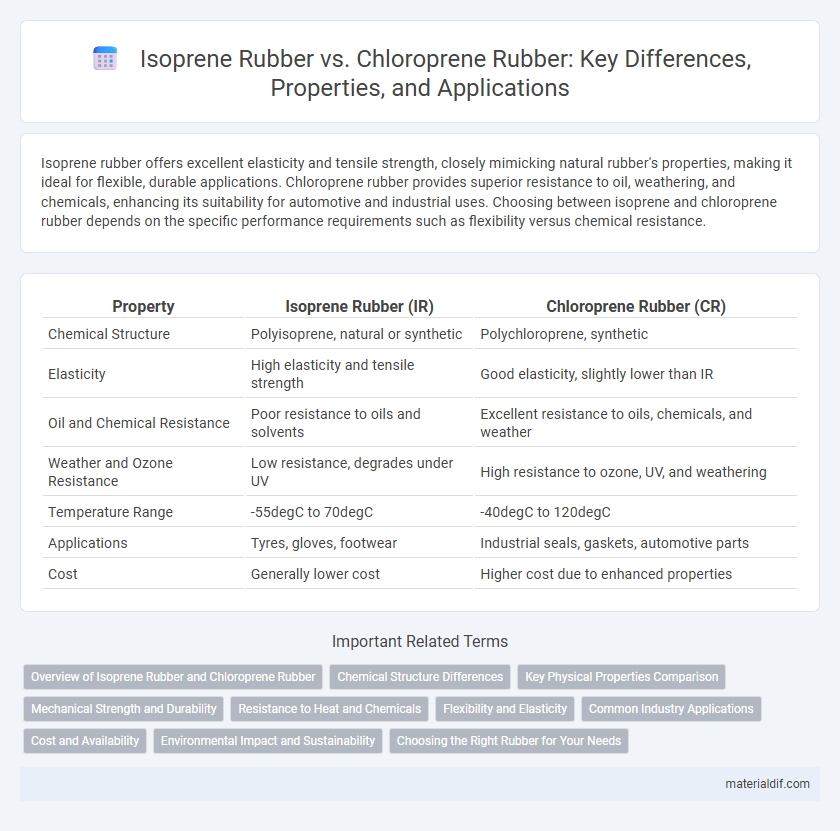

| Property | Isoprene Rubber (IR) | Chloroprene Rubber (CR) |

|---|---|---|

| Chemical Structure | Polyisoprene, natural or synthetic | Polychloroprene, synthetic |

| Elasticity | High elasticity and tensile strength | Good elasticity, slightly lower than IR |

| Oil and Chemical Resistance | Poor resistance to oils and solvents | Excellent resistance to oils, chemicals, and weather |

| Weather and Ozone Resistance | Low resistance, degrades under UV | High resistance to ozone, UV, and weathering |

| Temperature Range | -55degC to 70degC | -40degC to 120degC |

| Applications | Tyres, gloves, footwear | Industrial seals, gaskets, automotive parts |

| Cost | Generally lower cost | Higher cost due to enhanced properties |

Overview of Isoprene Rubber and Chloroprene Rubber

Isoprene rubber, a synthetic elastomer chemically similar to natural rubber, offers excellent elasticity, resilience, and abrasion resistance, making it ideal for automotive tires, footwear, and medical devices. Chloroprene rubber, also known as Neoprene, provides superior chemical stability, weather resistance, and flame retardancy, often used in wetsuits, gaskets, and adhesives. Both rubbers serve distinct industrial applications due to their unique molecular structures and physical properties.

Chemical Structure Differences

Isoprene rubber consists of repeating units of isoprene monomers with a cis-1,4-polyisoprene structure, providing excellent elasticity and resilience. Chloroprene rubber contains chlorinated diene monomers, specifically 2-chloro-1,3-butadiene, resulting in enhanced chemical resistance and flame retardancy due to the presence of chlorine atoms in its polymer chain. These fundamental chemical structure differences influence their physical properties and suitable industrial applications.

Key Physical Properties Comparison

Isoprene rubber features excellent tensile strength and high resilience, making it ideal for applications requiring flexibility and durability. Chloroprene rubber offers superior resistance to oil, chemicals, and weathering, with enhanced abrasion resistance compared to isoprene rubber. Both materials exhibit distinct hardness and elongation properties, where isoprene typically shows higher elasticity and chloroprene provides greater firmness and chemical stability.

Mechanical Strength and Durability

Isoprene rubber exhibits excellent tensile strength and elasticity, making it highly resistant to wear and fatigue in dynamic applications. Chloroprene rubber offers superior resistance to chemicals, ozone, and weather aging, enhancing its durability in harsh environmental conditions. Mechanical strength of chloroprene often surpasses isoprene in applications requiring robust resistance to oil and heat exposure.

Resistance to Heat and Chemicals

Isoprene rubber exhibits excellent resistance to heat with a maximum continuous operating temperature of approximately 100degC, making it suitable for applications requiring moderate thermal stability. Chloroprene rubber (neoprene) offers superior chemical resistance, especially against oils, greases, and solvents, and withstands heat up to about 120degC, providing enhanced durability in harsher environments. The choice between isoprene and chloroprene rubbers depends on the specific thermal and chemical exposure conditions of the application.

Flexibility and Elasticity

Isoprene rubber exhibits superior flexibility and elasticity due to its high cis-1,4-polyisoprene content, closely mimicking natural rubber's properties, making it ideal for applications requiring extensive stretch and recovery. Chloroprene rubber, while less flexible, offers enhanced resistance to oils, chemicals, and weathering, but its elasticity is comparatively lower due to the presence of chlorine atoms disrupting polymer chain mobility. Both rubbers serve distinct purposes, with isoprene preferred in dynamic sealing and flexible components, whereas chloroprene excels in durable, weather-resistant products.

Common Industry Applications

Isoprene rubber is extensively used in manufacturing automotive tires, footwear, and medical gloves due to its excellent elasticity and resistance to wear. Chloroprene rubber is preferred for industrial applications requiring enhanced chemical, oil, and weather resistance, such as conveyor belts, hoses, and gaskets. Both materials serve critical roles in industries like automotive, healthcare, and manufacturing, with their distinct properties driving specific application choices.

Cost and Availability

Isoprene rubber generally offers a lower cost due to its simpler production process and widespread availability, making it a popular choice in applications requiring natural-like properties. Chloroprene rubber tends to be more expensive because of its complex manufacturing and superior chemical resistance, yet it remains readily available for industrial uses such as automotive and construction. Market fluctuations in crude oil prices and raw material supply chains significantly influence the cost and availability of both synthetic rubbers.

Environmental Impact and Sustainability

Isoprene rubber, derived from renewable natural sources, offers superior biodegradability and a lower carbon footprint compared to chloroprene rubber, which is synthesized from petrochemical feedstocks. Chloroprene rubber production emits significant levels of hazardous chemicals such as vinyl chloride, impacting air quality and requiring stringent environmental controls. Sustainable practices favor isoprene due to its reduced environmental toxicity and compatibility with eco-friendly manufacturing processes.

Choosing the Right Rubber for Your Needs

Isoprene rubber offers excellent resilience, low compression set, and high tensile strength, making it ideal for applications requiring durability and flexibility such as medical devices and automotive parts. Chloroprene rubber provides superior resistance to ozone, weathering, oils, and flame, making it suitable for industrial seals, gaskets, and protective coatings exposed to harsh environments. Selecting the right rubber depends on the specific demands of the application, including environmental exposure, mechanical stress, and chemical compatibility.

Isoprene Rubber vs Chloroprene Rubber Infographic

materialdif.com

materialdif.com