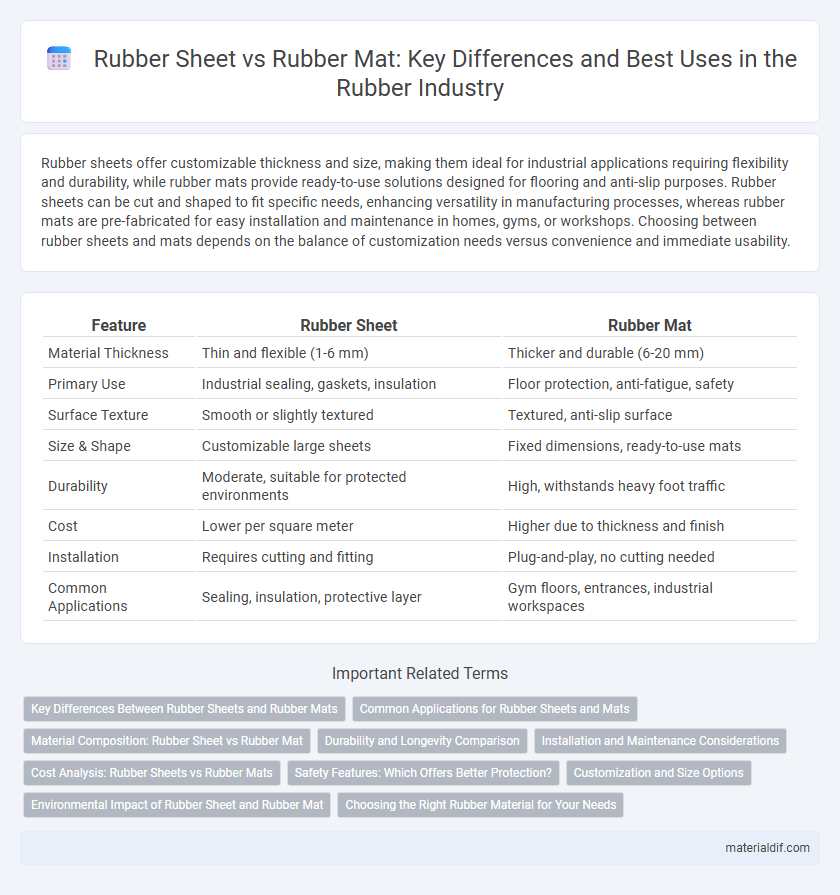

Rubber sheets offer customizable thickness and size, making them ideal for industrial applications requiring flexibility and durability, while rubber mats provide ready-to-use solutions designed for flooring and anti-slip purposes. Rubber sheets can be cut and shaped to fit specific needs, enhancing versatility in manufacturing processes, whereas rubber mats are pre-fabricated for easy installation and maintenance in homes, gyms, or workshops. Choosing between rubber sheets and mats depends on the balance of customization needs versus convenience and immediate usability.

Table of Comparison

| Feature | Rubber Sheet | Rubber Mat |

|---|---|---|

| Material Thickness | Thin and flexible (1-6 mm) | Thicker and durable (6-20 mm) |

| Primary Use | Industrial sealing, gaskets, insulation | Floor protection, anti-fatigue, safety |

| Surface Texture | Smooth or slightly textured | Textured, anti-slip surface |

| Size & Shape | Customizable large sheets | Fixed dimensions, ready-to-use mats |

| Durability | Moderate, suitable for protected environments | High, withstands heavy foot traffic |

| Cost | Lower per square meter | Higher due to thickness and finish |

| Installation | Requires cutting and fitting | Plug-and-play, no cutting needed |

| Common Applications | Sealing, insulation, protective layer | Gym floors, entrances, industrial workspaces |

Key Differences Between Rubber Sheets and Rubber Mats

Rubber sheets are flexible, thin, and often sold in rolls or cut-to-size pieces primarily used for insulation, gasketing, and vibration dampening, while rubber mats are thicker, heavier, and designed for floor covering, anti-slip surfaces, and impact resistance. Rubber sheets provide customization in thickness and texture for specific industrial applications, whereas rubber mats offer durability and cushioning suitable for gym floors, workshops, and entryways. The key difference lies in their form factor, application focus, and durability requirements, influencing material choice based on operational needs.

Common Applications for Rubber Sheets and Mats

Rubber sheets are widely used in industrial sealing, gaskets, and insulation due to their customizable thickness and flexibility, making them ideal for machinery protection and chemical resistance. Rubber mats serve applications such as flooring for gyms, anti-fatigue workstations, and slip-resistant surfaces, providing durability and cushioning in both commercial and residential settings. Both products offer essential solutions for impact absorption and surface protection across diverse industries.

Material Composition: Rubber Sheet vs Rubber Mat

Rubber sheets are typically made from high-quality natural or synthetic rubber compounds designed for uniform thickness and consistent tensile strength, ideal for industrial sealing and gasketing. Rubber mats often incorporate recycled rubber blended with additives to enhance durability and abrasion resistance, making them suitable for flooring and cushioning applications. The difference in material composition between rubber sheets and mats directly influences their flexibility, resilience, and suitability for specific environmental conditions.

Durability and Longevity Comparison

Rubber sheets typically offer greater durability and longevity due to their uniform thickness and ability to withstand heavy industrial usage without tearing or deforming. Rubber mats, while versatile and easier to install, often have thinner profiles and may wear out faster under constant pressure or abrasion. Choosing rubber sheets is ideal for applications requiring sustained resistance to wear, chemicals, and environmental factors over extended periods.

Installation and Maintenance Considerations

Rubber sheets offer easier installation due to their lightweight and flexibility, making them ideal for custom-cut applications and seamless coverage. Rubber mats generally require less maintenance as they can be easily removed, cleaned, and replaced, which is beneficial in high-traffic or industrial environments. Both options demand attention to surface preparation and regular inspection to prevent wear, but rubber sheets often need adhesive for secure installation, while mats rely on weight and texture for stability.

Cost Analysis: Rubber Sheets vs Rubber Mats

Rubber sheets generally offer a lower cost per square foot compared to rubber mats, making them a more economical choice for large-scale industrial applications requiring custom sizes. Rubber mats, often pre-cut and thicker with added texture or cushioning, tend to be pricier due to manufacturing complexity and convenience features. Cost analysis should consider not only initial purchase price but also durability, installation ease, and intended usage to determine overall value between rubber sheets and mats.

Safety Features: Which Offers Better Protection?

Rubber sheets provide customizable thickness and density options that enhance impact resistance and abrasion protection, making them ideal for heavy-duty industrial safety applications. Rubber mats often include textured surfaces or anti-slip properties designed to prevent slips and falls in workplaces, boosting user safety on wet or oily floors. Choosing between rubber sheets and mats depends on whether the primary safety concern is cushioning against heavy impacts or enhancing footing stability in hazardous environments.

Customization and Size Options

Rubber sheets offer extensive customization in thickness, hardness, and surface texture, allowing precise adaptation for industrial applications and specific performance needs. Rubber mats, while available in various sizes, often come in standard dimensions designed for general purposes, limiting size flexibility but providing convenient, ready-to-use solutions. Choosing between a rubber sheet and rubber mat depends on the necessity for bespoke sizing and material properties versus immediate usability and standardization.

Environmental Impact of Rubber Sheet and Rubber Mat

Rubber sheets generally have a lower environmental impact due to their simpler manufacturing process and reduced material thickness compared to rubber mats. Rubber mats often contain additional additives and reinforcements that increase resource consumption and complicate recycling efforts. The biodegradability and lifecycle emissions of rubber sheets are typically more favorable, contributing to a smaller ecological footprint.

Choosing the Right Rubber Material for Your Needs

Rubber sheets offer greater versatility and customization in thickness and size, making them ideal for industrial applications requiring specific dimensions and durability. Rubber mats, designed for slip resistance and cushioning, provide excellent safety and comfort for flooring in gyms and workplaces. Selecting the right rubber material depends on factors such as environmental exposure, load-bearing requirements, and whether flexibility or impact absorption is the priority.

Rubber Sheet vs Rubber Mat Infographic

materialdif.com

materialdif.com