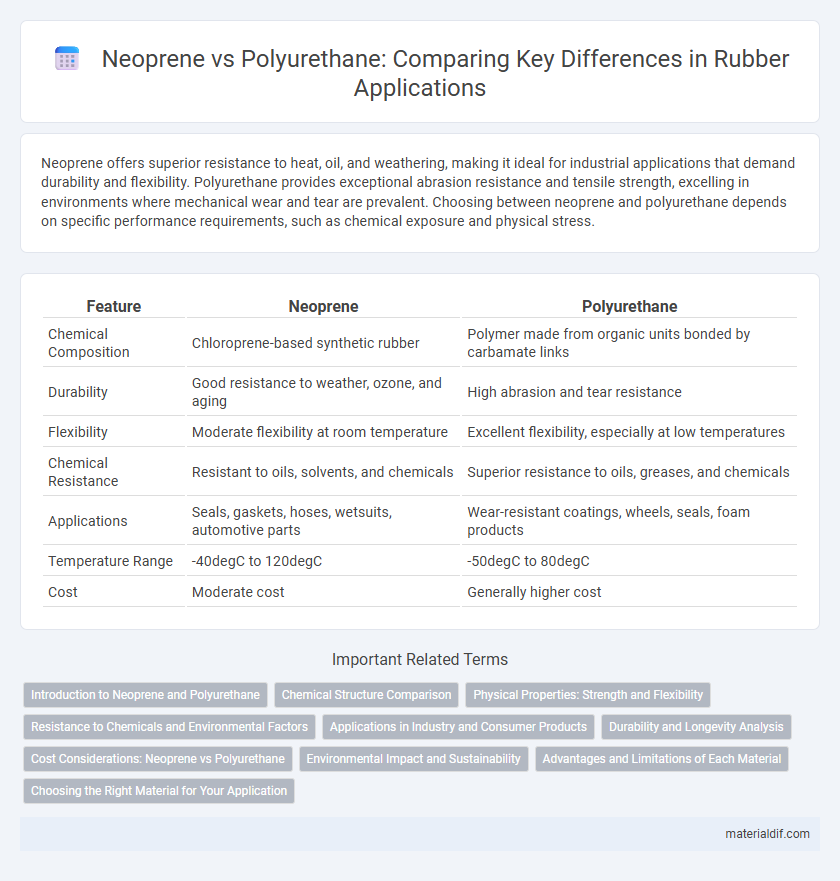

Neoprene offers superior resistance to heat, oil, and weathering, making it ideal for industrial applications that demand durability and flexibility. Polyurethane provides exceptional abrasion resistance and tensile strength, excelling in environments where mechanical wear and tear are prevalent. Choosing between neoprene and polyurethane depends on specific performance requirements, such as chemical exposure and physical stress.

Table of Comparison

| Feature | Neoprene | Polyurethane |

|---|---|---|

| Chemical Composition | Chloroprene-based synthetic rubber | Polymer made from organic units bonded by carbamate links |

| Durability | Good resistance to weather, ozone, and aging | High abrasion and tear resistance |

| Flexibility | Moderate flexibility at room temperature | Excellent flexibility, especially at low temperatures |

| Chemical Resistance | Resistant to oils, solvents, and chemicals | Superior resistance to oils, greases, and chemicals |

| Applications | Seals, gaskets, hoses, wetsuits, automotive parts | Wear-resistant coatings, wheels, seals, foam products |

| Temperature Range | -40degC to 120degC | -50degC to 80degC |

| Cost | Moderate cost | Generally higher cost |

Introduction to Neoprene and Polyurethane

Neoprene is a synthetic rubber known for its excellent chemical stability, flexibility, and resistance to weathering, oils, and heat, making it ideal for industrial applications such as gaskets and hoses. Polyurethane, a versatile polymer, offers superior abrasion resistance, elasticity, and load-bearing capacity, commonly used in automotive parts, coatings, and wheels. Both materials serve distinct purposes in manufacturing due to their unique physical properties and durability under different environmental conditions.

Chemical Structure Comparison

Neoprene is a synthetic rubber derived from chloroprene monomers, characterized by a stable polychloroprene backbone that provides excellent chemical resistance and weatherability. Polyurethane consists of linear or crosslinked chains formed by reacting diisocyanates with polyols, offering higher flexibility and abrasion resistance due to its segmented polymer structure with hard and soft segments. The chlorine atoms in neoprene's chemical structure enhance its flame retardancy, whereas the urethane linkages in polyurethane impart superior elasticity and durability in dynamic applications.

Physical Properties: Strength and Flexibility

Neoprene exhibits excellent tensile strength and moderate flexibility, making it resistant to abrasion, oils, and weathering, which is ideal for seals and gaskets. Polyurethane offers superior tensile strength and remarkable elasticity, providing higher resistance to wear and tear and exceptional flexibility for applications requiring frequent movement. The choice between neoprene and polyurethane depends on the balance needed between durability and flexibility in industrial or commercial rubber products.

Resistance to Chemicals and Environmental Factors

Neoprene exhibits excellent resistance to oils, solvents, and weathering, maintaining durability in harsh chemical environments and extreme temperatures. Polyurethane offers superior abrasion resistance and performs well against oils, greases, and certain solvents but is less effective against ozone and UV exposure compared to neoprene. For applications demanding long-term environmental resilience and chemical stability, neoprene is typically preferred, while polyurethane excels in mechanical wear resistance.

Applications in Industry and Consumer Products

Neoprene excels in industrial applications such as gaskets, hoses, and protective coatings due to its superior chemical resistance and durability against oils and weathering. Polyurethane is favored in consumer products like footwear soles, adhesives, and flexible foam cushioning for its exceptional abrasion resistance and elasticity. Both materials serve distinct roles, with neoprene preferred for harsh environments and polyurethane chosen for comfort and flexibility in everyday items.

Durability and Longevity Analysis

Neoprene exhibits superior resistance to weathering, ozone, and chemical degradation, making it highly durable in harsh environments, while polyurethane offers exceptional abrasion resistance and tensile strength, extending product longevity under mechanical stress. The molecular structure of neoprene provides inherent elasticity and flexibility, which maintains performance in fluctuating temperatures, whereas polyurethane's cross-linked polymer chains enhance wear resistance and impact absorption. Both materials demonstrate long service life, but neoprene excels in chemical stability and environmental resilience, while polyurethane is preferred for applications requiring high physical endurance and resilience.

Cost Considerations: Neoprene vs Polyurethane

Neoprene typically offers a more cost-effective solution compared to polyurethane, with prices generally lower due to its simpler manufacturing process and widespread availability. Polyurethane, while more expensive, provides superior abrasion resistance and flexibility, which may justify the higher initial investment in applications demanding durability. Budget constraints and performance requirements ultimately guide the choice between neoprene's affordability and polyurethane's advanced material properties.

Environmental Impact and Sustainability

Neoprene production relies heavily on petroleum-based raw materials, resulting in significant carbon emissions and limited biodegradability, which challenges its environmental sustainability. In contrast, polyurethane offers better potential for recyclability and lower volatile organic compound (VOC) emissions during manufacturing, making it a more eco-friendly alternative in rubber applications. However, both materials require advancements in recycling technologies and the development of bio-based feedstocks to enhance their overall environmental impact.

Advantages and Limitations of Each Material

Neoprene offers excellent chemical stability, weather resistance, and flexibility, making it ideal for applications like wetsuits, gaskets, and hoses, but it can degrade under prolonged exposure to oils and solvents. Polyurethane excels in abrasion resistance, elasticity, and load-bearing capabilities, making it suitable for wheels, seals, and industrial rollers; however, it tends to be less resistant to UV light and hydrolysis compared to neoprene. The choice between neoprene and polyurethane depends on the specific environmental conditions and mechanical demands of the application.

Choosing the Right Material for Your Application

Neoprene offers excellent chemical stability, temperature resistance, and weathering durability, making it ideal for automotive and industrial seals. Polyurethane provides superior abrasion resistance and tensile strength, suitable for heavy-duty applications like conveyor belts and hydraulic seals. Selecting the right material depends on factors such as environmental exposure, mechanical stress, and the required lifespan of the rubber component.

Neoprene vs Polyurethane Infographic

materialdif.com

materialdif.com