SBR (Styrene-Butadiene Rubber) offers excellent abrasion resistance and cost-effectiveness, making it ideal for automotive tires and industrial applications. BR (Butadiene Rubber) provides superior elasticity and impact resistance, which enhances performance in high-stress environments like tire sidewalls and sports equipment. Choosing between SBR and BR depends on the balance between durability, flexibility, and driving conditions required for specific rubber products.

Table of Comparison

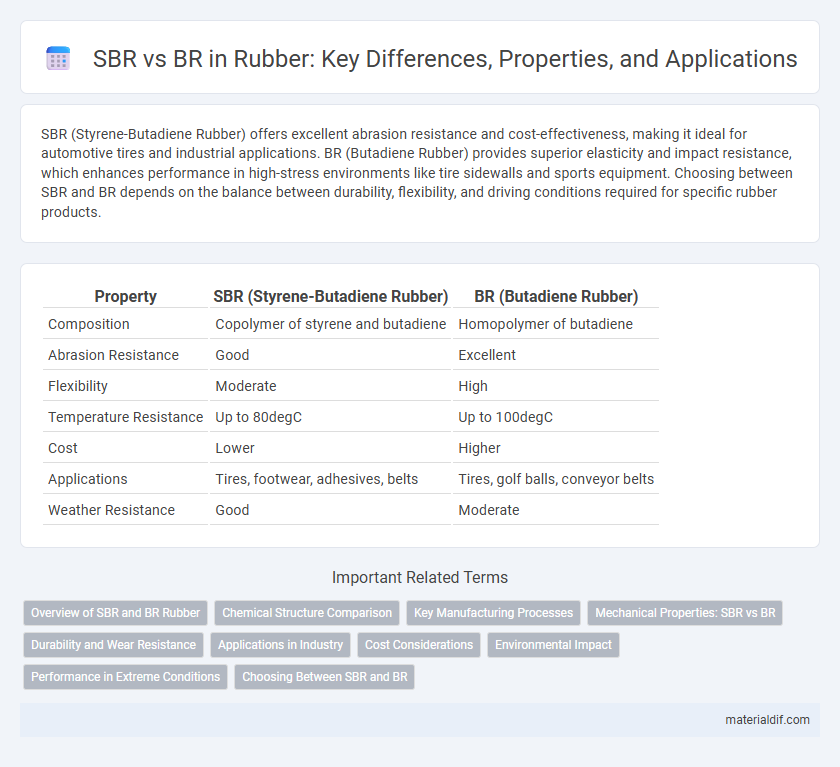

| Property | SBR (Styrene-Butadiene Rubber) | BR (Butadiene Rubber) |

|---|---|---|

| Composition | Copolymer of styrene and butadiene | Homopolymer of butadiene |

| Abrasion Resistance | Good | Excellent |

| Flexibility | Moderate | High |

| Temperature Resistance | Up to 80degC | Up to 100degC |

| Cost | Lower | Higher |

| Applications | Tires, footwear, adhesives, belts | Tires, golf balls, conveyor belts |

| Weather Resistance | Good | Moderate |

Overview of SBR and BR Rubber

SBR (Styrene-Butadiene Rubber) is a synthetic rubber known for its excellent abrasion resistance and aging stability, commonly used in tire treads and industrial belts. BR (Butadiene Rubber) offers superior elasticity and low-temperature flexibility, making it ideal for high-performance tires and impact-resistant products. Both SBR and BR are widely utilized in the automotive and manufacturing industries due to their complementary properties enhancing durability and performance.

Chemical Structure Comparison

Styrene-Butadiene Rubber (SBR) consists of styrene and butadiene monomers arranged in a random copolymer structure, providing a balance of rigidity and elasticity due to the aromatic styrene and flexible butadiene units. In contrast, Polybutadiene Rubber (BR) is composed predominantly of cis-1,4-butadiene units, resulting in a highly flexible polymer chain with low glass transition temperature and excellent resistance to wear and impact. The presence of styrene in SBR introduces polarity and increases the glass transition temperature compared to BR, which solely features nonpolar hydrocarbon chains allowing greater chain mobility and resilience.

Key Manufacturing Processes

Styrene-Butadiene Rubber (SBR) is primarily produced through emulsion polymerization, a process that offers better control over polymer properties and enables large-scale production. In contrast, Butadiene Rubber (BR) is typically synthesized via solution polymerization, resulting in higher molecular weight and enhanced elasticity ideal for tire manufacturing. Both methods influence the final rubber's mechanical properties, with SBR favoring abrasion resistance and BR excelling in resilience and low-temperature flexibility.

Mechanical Properties: SBR vs BR

Styrene-Butadiene Rubber (SBR) exhibits higher abrasion resistance and good aging stability, making it suitable for applications requiring durability under wear. Butadiene Rubber (BR) provides superior elasticity, tensile strength, and resilience, enhancing performance in dynamic environments and improving impact resistance. Mechanical properties of SBR favor static and low-speed uses, whereas BR excels in high-speed, high-impact applications due to its enhanced fatigue resistance.

Durability and Wear Resistance

Styrene-butadiene rubber (SBR) exhibits superior abrasion resistance and durability compared to butadiene rubber (BR), making it ideal for applications requiring long-lasting wear performance. BR offers better resilience and flexibility but generally has lower wear resistance, limiting its effectiveness in high-friction environments. The enhanced toughness of SBR results from its styrene content, which improves hardness and reduces degradation under mechanical stress.

Applications in Industry

SBR (Styrene-Butadiene Rubber) is widely used in tire manufacturing, conveyor belts, and footwear due to its excellent abrasion resistance and aging stability. BR (Butadiene Rubber) is preferred in high-performance tires, golf balls, and mechanical rubber goods for its superior elasticity and low-temperature flexibility. Both rubbers play critical roles in automotive and industrial sectors, optimizing durability and performance based on specific application requirements.

Cost Considerations

SBR (Styrene-Butadiene Rubber) typically offers a more cost-effective solution compared to BR (Butadiene Rubber) due to its lower raw material expenses and widespread availability. Manufacturing processes for SBR benefit from economies of scale, resulting in reduced production costs that are attractive for high-volume applications like tires and footwear. Although BR provides superior abrasion resistance and elasticity, its higher price point makes SBR the preferred choice when budget constraints are critical.

Environmental Impact

Styrene-Butadiene Rubber (SBR) and Butadiene Rubber (BR) differ significantly in environmental impact due to their production processes and end-of-life degradation. SBR, synthesized through emulsion polymerization with high energy consumption and use of hazardous chemicals, poses greater pollution risks compared to BR, which is produced via solution polymerization with lower emissions. Both rubbers contribute to microplastic pollution, but BR's higher resilience often results in longer environmental persistence, influencing waste management strategies.

Performance in Extreme Conditions

Styrene-Butadiene Rubber (SBR) exhibits superior abrasion resistance and aging stability, making it ideal for automotive tires and seals exposed to moderate temperatures and wear. In contrast, Butadiene Rubber (BR) offers excellent low-temperature flexibility and enhanced resilience to heat, providing better performance in extreme cold and high-temperature environments such as industrial machinery and high-performance tires. Both rubbers excel in specific conditions, but BR's superior elasticity and weather resistance make it more suitable for demanding applications requiring durability under severe thermal stress.

Choosing Between SBR and BR

Choosing between Styrene-Butadiene Rubber (SBR) and Butadiene Rubber (BR) depends on specific performance requirements and application conditions. SBR offers superior abrasion resistance and aging stability, making it ideal for tire treads and conveyor belts, while BR provides better resilience and lower heat build-up, preferred in high-performance tires and golf balls. Cost considerations and environmental exposure also play critical roles in selecting the appropriate synthetic rubber type.

SBR vs BR Infographic

materialdif.com

materialdif.com