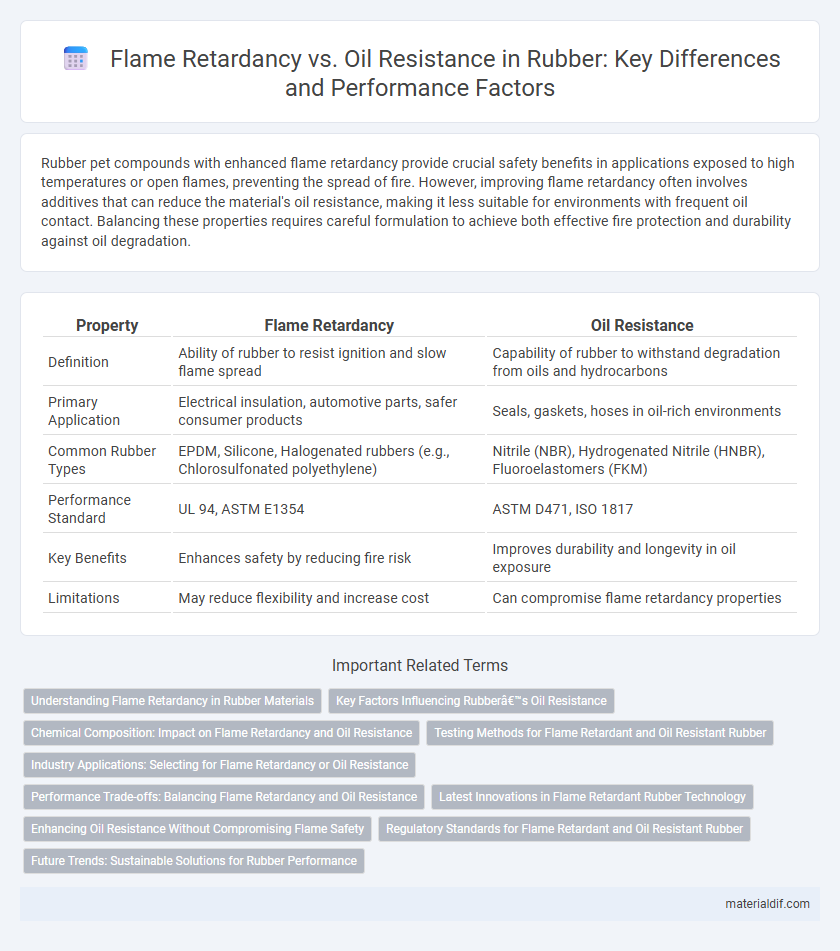

Rubber pet compounds with enhanced flame retardancy provide crucial safety benefits in applications exposed to high temperatures or open flames, preventing the spread of fire. However, improving flame retardancy often involves additives that can reduce the material's oil resistance, making it less suitable for environments with frequent oil contact. Balancing these properties requires careful formulation to achieve both effective fire protection and durability against oil degradation.

Table of Comparison

| Property | Flame Retardancy | Oil Resistance |

|---|---|---|

| Definition | Ability of rubber to resist ignition and slow flame spread | Capability of rubber to withstand degradation from oils and hydrocarbons |

| Primary Application | Electrical insulation, automotive parts, safer consumer products | Seals, gaskets, hoses in oil-rich environments |

| Common Rubber Types | EPDM, Silicone, Halogenated rubbers (e.g., Chlorosulfonated polyethylene) | Nitrile (NBR), Hydrogenated Nitrile (HNBR), Fluoroelastomers (FKM) |

| Performance Standard | UL 94, ASTM E1354 | ASTM D471, ISO 1817 |

| Key Benefits | Enhances safety by reducing fire risk | Improves durability and longevity in oil exposure |

| Limitations | May reduce flexibility and increase cost | Can compromise flame retardancy properties |

Understanding Flame Retardancy in Rubber Materials

Flame retardancy in rubber materials is achieved through the incorporation of specific additives like halogenated compounds, phosphorus-based agents, or mineral fillers such as aluminum hydroxide, which inhibit ignition and slow combustion. Understanding the chemical interaction between these flame retardants and the rubber matrix is crucial for optimizing performance without compromising mechanical properties. While oil resistance primarily relates to the polymer's saturation level and crosslink density, flame retardancy focuses on thermal stability and the material's ability to resist flame propagation under high-temperature conditions.

Key Factors Influencing Rubber’s Oil Resistance

Rubber's oil resistance is primarily influenced by the type of polymer used, with nitrile and fluorocarbon rubbers exhibiting superior resistance due to their chemical structure. Crosslink density and filler content also play crucial roles in enhancing the material's barrier properties against oil penetration. Temperature and exposure duration further affect the degradation rate, making formulation optimization essential for maintaining oil resistance in demanding environments.

Chemical Composition: Impact on Flame Retardancy and Oil Resistance

Flame retardancy in rubber is often achieved by incorporating halogenated compounds, phosphorus-based additives, or metal hydroxides, which chemically inhibit combustion but can reduce oil resistance due to polar interactions. Oil resistance depends on the rubber's polymer structure, such as nitrile butadiene rubber (NBR) containing polar acrylonitrile groups that resist oil swelling but may decrease flame retardant effectiveness. Understanding the balance between chemical composition--halogen or phosphorus content for flame retardancy versus polar monomers for oil resistance--is crucial for optimizing rubber performance in applications requiring both properties.

Testing Methods for Flame Retardant and Oil Resistant Rubber

Testing methods for flame retardant rubber primarily involve standardized flame resistance tests such as UL 94, ASTM D3801, and ISO 1210, measuring ignition resistance, flame spread, and self-extinguishing properties. Oil resistant rubber undergoes evaluation through ASTM D471 and ISO 1817, which assess swelling, weight change, and mechanical property retention after exposure to various oils and hydrocarbons. Accurate testing ensures that flame retardant rubber meets fire safety standards, while oil resistant rubber maintains durability and performance in harsh chemical environments.

Industry Applications: Selecting for Flame Retardancy or Oil Resistance

Flame retardant rubber is essential in electrical and automotive industries where fire safety standards demand materials that resist ignition and slow flame spread. Oil-resistant rubber is critical in manufacturing sectors like automotive, industrial machinery, and oil drilling, providing durability against hydrocarbon exposure and preventing material degradation. Selecting rubber based on flame retardancy or oil resistance depends on the specific application requirements, balancing safety protocols with chemical exposure conditions.

Performance Trade-offs: Balancing Flame Retardancy and Oil Resistance

Achieving optimal flame retardancy in rubber compounds often compromises oil resistance due to the chemical additives required, which can degrade the polymer's hydrocarbon stability. Enhanced oil resistance typically relies on polymers like nitrile or fluorocarbon rubbers that inherently resist hydrocarbon swelling but may lack sufficient flame retardant properties. Balancing these performance trade-offs requires carefully selecting and combining fillers, plasticizers, and flame retardant agents to meet specific application needs without sacrificing durability or safety standards.

Latest Innovations in Flame Retardant Rubber Technology

Recent advancements in flame retardant rubber technology emphasize the integration of novel phosphorus-based compounds and nanomaterial additives to enhance fire resistance without compromising oil resistance. These innovations enable rubber products to meet stringent safety standards in automotive and industrial applications where exposure to oils and flames is frequent. Enhanced formulations demonstrate improved thermal stability and reduced smoke generation, setting new benchmarks for multifunctional rubber materials.

Enhancing Oil Resistance Without Compromising Flame Safety

Enhancing oil resistance in rubber compounds requires balancing polymer selection and additive incorporation to maintain flame retardancy without sacrificing durability. Incorporating silicone-based oils or fluorinated additives can improve oil resistance while preserving the material's inherent flame-retardant properties. Advanced fillers like layered silicates or intumescent agents optimize the rubber's performance by enhancing both oil resistance and flame safety simultaneously.

Regulatory Standards for Flame Retardant and Oil Resistant Rubber

Regulatory standards for flame retardant rubber typically require compliance with UL 94, FMVSS 302, or EN 45545, focusing on limiting flammability and smoke emission. Oil resistant rubber must meet ASTM D2000 classifications and industry-specific standards such as NBR (Nitrile Butadiene Rubber) compliance for resistance to hydrocarbons and oils. Both flame retardant and oil resistant rubbers are tested under strict protocols to ensure safety, durability, and performance in their respective applications.

Future Trends: Sustainable Solutions for Rubber Performance

Innovations in flame retardancy for rubber focus on non-toxic, halogen-free additives that enhance safety while maintaining material integrity. Oil resistance advancements prioritize bio-based fillers and polymer blends to improve durability without compromising environmental impact. Future trends emphasize developing sustainable rubber formulations that balance flame retardant properties with superior oil resistance for diverse industrial applications.

Flame Retardancy vs Oil Resistance Infographic

materialdif.com

materialdif.com