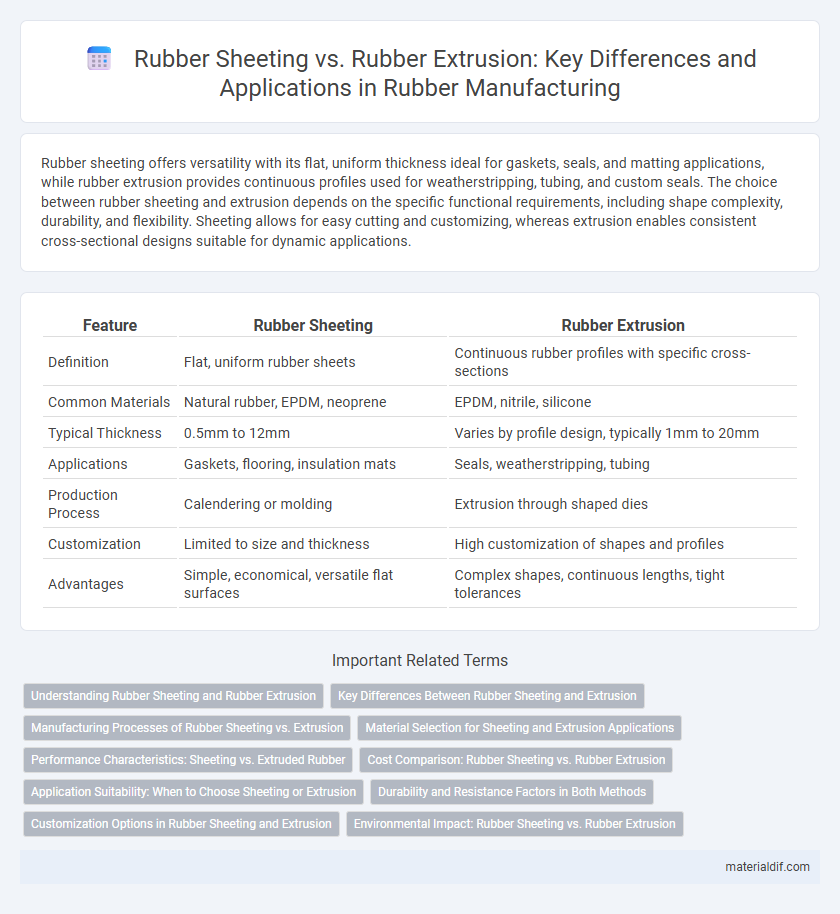

Rubber sheeting offers versatility with its flat, uniform thickness ideal for gaskets, seals, and matting applications, while rubber extrusion provides continuous profiles used for weatherstripping, tubing, and custom seals. The choice between rubber sheeting and extrusion depends on the specific functional requirements, including shape complexity, durability, and flexibility. Sheeting allows for easy cutting and customizing, whereas extrusion enables consistent cross-sectional designs suitable for dynamic applications.

Table of Comparison

| Feature | Rubber Sheeting | Rubber Extrusion |

|---|---|---|

| Definition | Flat, uniform rubber sheets | Continuous rubber profiles with specific cross-sections |

| Common Materials | Natural rubber, EPDM, neoprene | EPDM, nitrile, silicone |

| Typical Thickness | 0.5mm to 12mm | Varies by profile design, typically 1mm to 20mm |

| Applications | Gaskets, flooring, insulation mats | Seals, weatherstripping, tubing |

| Production Process | Calendering or molding | Extrusion through shaped dies |

| Customization | Limited to size and thickness | High customization of shapes and profiles |

| Advantages | Simple, economical, versatile flat surfaces | Complex shapes, continuous lengths, tight tolerances |

Understanding Rubber Sheeting and Rubber Extrusion

Rubber sheeting refers to flat, uniform sheets produced through calendaring or molding processes, ideal for sealing, gasketing, and cushioning applications. Rubber extrusion involves forcing rubber compounds through a shaped die to create continuous profiles like tubes, strips, or custom cross-sections used in weatherstripping, hoses, and edge trims. Understanding these manufacturing methods helps select the appropriate rubber product based on application requirements, material properties, and production efficiency.

Key Differences Between Rubber Sheeting and Extrusion

Rubber sheeting is a flat, uniform material produced by calendaring or molding, ideal for sealing, insulation, and gasketing applications, whereas rubber extrusion involves forcing rubber through a die to create continuous profiles like tubes, strips, or specialized shapes. Sheeting offers consistent thickness and surface area, making it suitable for cutting into custom shapes, while extrusions provide complex cross-sectional designs and lengths tailored to specific mechanical or structural uses. The key difference lies in their manufacturing processes and resulting forms, with sheeting emphasizing surface coverage and extrusions focusing on precise profiles and flexibility in design.

Manufacturing Processes of Rubber Sheeting vs. Extrusion

Rubber sheeting manufacturing involves calendaring, where rubber compound is passed through rollers to produce thin, uniform sheets with specific thickness and surface properties. Rubber extrusion uses an extruder machine to push heated rubber through a shaped die, forming continuous profiles like tubes, seals, or gaskets. Calendaring offers precise thickness control and smooth surfaces, while extrusion provides versatile cross-sectional shapes for various industrial applications.

Material Selection for Sheeting and Extrusion Applications

Rubber sheeting generally requires materials with excellent flexibility, elasticity, and resistance to abrasion, making natural rubber (NR) and neoprene (CR) optimal choices for applications like gaskets and seals. Rubber extrusion demands materials with good flow properties and dimensional stability during processing, typically favoring ethylene propylene diene monomer (EPDM) or silicone rubber for tubing and weatherstripping. Selecting the correct compound depends on factors such as chemical exposure, temperature range, and mechanical stress associated with the specific sheeting or extrusion use.

Performance Characteristics: Sheeting vs. Extruded Rubber

Rubber sheeting offers uniform thickness and is ideal for gasketing, sealing, and vibration dampening applications requiring flexibility and resilience under compression. Extruded rubber provides consistent cross-sectional profiles suited for dynamic seals, weatherstripping, and edge trims where precise dimensions and enhanced abrasion resistance are critical. Sheeting generally excels in static applications, while extrusions perform better under repeated motion and environmental exposure.

Cost Comparison: Rubber Sheeting vs. Rubber Extrusion

Rubber sheeting often presents a more cost-effective solution for large surface areas due to its uniform thickness and ease of production, reducing material waste and labor expenses. Rubber extrusion involves higher initial tooling costs but offers advantages in producing continuous profiles with complex cross-sections, making it economical for specialized, high-volume applications. Comparing unit costs, rubber sheeting typically has lower per-unit prices for flat applications, whereas extrusion's cost-efficiency increases with production scale and design complexity.

Application Suitability: When to Choose Sheeting or Extrusion

Rubber sheeting offers versatility for large surface coverage, ideal for gaskets, seals, and protective mats in automotive, industrial, and construction applications. Rubber extrusion is best suited for creating custom profiles like tubing, weatherstripping, and edge trims, providing precision and consistent cross-sectional shapes. Choose sheeting for broad, flat applications requiring flexibility, while extrusion is preferred for intricate, continuous shapes demanding durability and exact dimensions.

Durability and Resistance Factors in Both Methods

Rubber sheeting offers superior durability through uniform thickness and enhanced resistance to abrasion, chemicals, and weathering, making it ideal for applications requiring flexible, protective surfaces. Rubber extrusion provides consistent dimensional accuracy and high tensile strength in complex profiles, delivering excellent resistance to mechanical stress and environmental factors. Both methods ensure robust performance, but choice depends on the specific requirements for flexibility, shape complexity, and exposure conditions.

Customization Options in Rubber Sheeting and Extrusion

Rubber sheeting offers extensive customization options, including varied thicknesses, widths, and compound formulations tailored to specific industrial applications such as sealing, gasketing, and impact absorption. Rubber extrusion allows for precise shaping into continuous profiles like tubing, seals, and strips, with customization focused on cross-sectional design and material elasticity to meet specialized functional requirements. Both methods enable material selection from natural and synthetic rubbers, but sheeting provides broader size versatility while extrusion excels in producing complex, consistent shapes for targeted performance.

Environmental Impact: Rubber Sheeting vs. Rubber Extrusion

Rubber sheeting typically generates less waste and requires lower energy consumption compared to rubber extrusion, making it a more environmentally sustainable option. The sheeting process allows for easier recycling and reuse of offcuts, whereas extrusion often produces scrap that is harder to reclaim. Furthermore, rubber extrusion involves higher emissions due to the continuous heating and shaping phases, increasing its carbon footprint relative to rubber sheeting.

Rubber Sheeting vs Rubber Extrusion Infographic

materialdif.com

materialdif.com