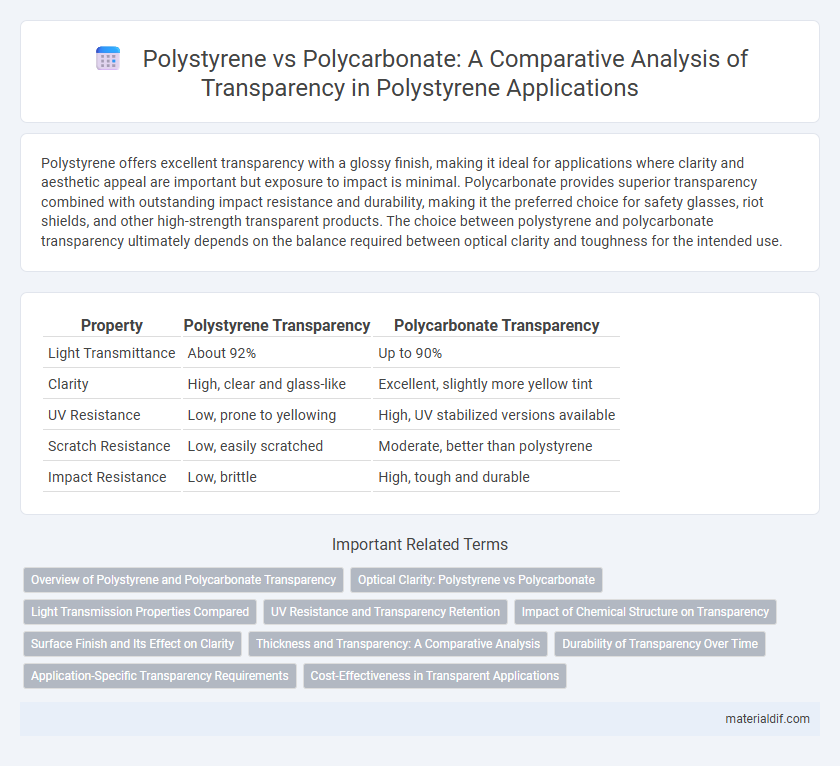

Polystyrene offers excellent transparency with a glossy finish, making it ideal for applications where clarity and aesthetic appeal are important but exposure to impact is minimal. Polycarbonate provides superior transparency combined with outstanding impact resistance and durability, making it the preferred choice for safety glasses, riot shields, and other high-strength transparent products. The choice between polystyrene and polycarbonate transparency ultimately depends on the balance required between optical clarity and toughness for the intended use.

Table of Comparison

| Property | Polystyrene Transparency | Polycarbonate Transparency |

|---|---|---|

| Light Transmittance | About 92% | Up to 90% |

| Clarity | High, clear and glass-like | Excellent, slightly more yellow tint |

| UV Resistance | Low, prone to yellowing | High, UV stabilized versions available |

| Scratch Resistance | Low, easily scratched | Moderate, better than polystyrene |

| Impact Resistance | Low, brittle | High, tough and durable |

Overview of Polystyrene and Polycarbonate Transparency

Polystyrene offers moderate transparency with a light transmittance of approximately 92%, making it suitable for applications requiring clear but less impact-resistant materials. Polycarbonate provides superior transparency, boasting up to 89% light transmittance while maintaining exceptional impact resistance and UV stability, ideal for demanding optical uses. The difference in transparency between polystyrene and polycarbonate directly influences their selection in packaging, glazing, and optical components, balancing clarity with durability.

Optical Clarity: Polystyrene vs Polycarbonate

Polystyrene offers excellent optical clarity with a light transmittance of around 92%, making it ideal for applications requiring clear, colorless transparency. Polycarbonate surpasses polystyrene in impact resistance while maintaining high optical clarity, with light transmittance typically between 88% and 90%. Both materials provide good transparency, but polycarbonate's superior durability makes it preferable in environments where strength and clarity are critical.

Light Transmission Properties Compared

Polystyrene exhibits a light transmission rate of approximately 90%, offering clear transparency suitable for applications requiring visual clarity at a lower cost. Polycarbonate surpasses polystyrene with light transmission rates reaching up to 88-92%, alongside superior impact resistance and UV protection, making it ideal for high-performance transparent materials. While both materials provide excellent clarity, polycarbonate's enhanced durability and resistance to yellowing under sunlight make it preferable for long-term optical applications.

UV Resistance and Transparency Retention

Polystyrene exhibits high initial transparency but suffers from poor UV resistance, leading to rapid yellowing and decreased clarity when exposed to sunlight. Polycarbonate maintains superior transparency retention over time due to its robust UV stabilizers and inherent resistance to photodegradation. This makes polycarbonate the preferred choice for applications requiring long-term clarity under UV exposure, such as eyewear lenses and outdoor glazing.

Impact of Chemical Structure on Transparency

Polystyrene exhibits high transparency due to its linear hydrocarbon structure, which allows for minimal light scattering and uniform polymer matrix formation. In contrast, polycarbonate's complex aromatic carbonate groups create a denser molecular arrangement, reducing transparency slightly but improving impact resistance. The chemical structure differences directly impact their optical clarity, with polystyrene providing superior transparency while polycarbonate balances transparency with enhanced durability.

Surface Finish and Its Effect on Clarity

Polystyrene typically offers high transparency with a smooth surface finish that enhances light transmission, but it is more prone to surface scratching which can degrade clarity over time. Polycarbonate provides superior impact resistance with a slightly less glossy surface, maintaining clarity better under rough handling and frequent cleaning. The surface finish quality directly influences the optical performance of both materials, where polystyrene's pristine, polished finish achieves clearer transparency initially, whereas polycarbonate sustains clarity through durable surface integrity.

Thickness and Transparency: A Comparative Analysis

Polystyrene offers excellent transparency with clarity typically around 92%, but its optical performance decreases significantly beyond thicknesses of 3-5 mm, leading to reduced light transmission and increased haze. Polycarbonate maintains high transparency, approximately 88-90%, even at greater thicknesses up to 12 mm, making it more suitable for applications requiring thicker, durable clear materials. The superior thickness tolerance of polycarbonate enables consistent clarity where polystyrene's transparency diminishes due to light scattering and internal stresses.

Durability of Transparency Over Time

Polystyrene exhibits good initial transparency but tends to yellow and lose clarity over time due to UV exposure and oxidation, reducing its long-term optical performance. In contrast, polycarbonate maintains superior transparency durability with higher resistance to yellowing and environmental degradation. This makes polycarbonate a preferred option for applications requiring sustained optical clarity and impact resistance.

Application-Specific Transparency Requirements

Polystyrene offers moderate transparency with a light transmittance of approximately 92%, making it suitable for applications like food packaging and disposable eyewear where cost-effectiveness is prioritized over optical clarity. Polycarbonate provides superior transparency, transmitting up to 88-90% of visible light with excellent impact resistance, ideal for safety glasses, automotive components, and electronic displays requiring high optical performance. Application-specific transparency requirements determine the material choice, balancing factors such as clarity, durability, and UV resistance.

Cost-Effectiveness in Transparent Applications

Polystyrene offers high transparency with excellent optical clarity at a significantly lower cost compared to polycarbonate, making it a cost-effective choice for budget-sensitive transparent applications. While polycarbonate provides superior impact resistance and durability, its higher price point limits its use to demanding environments where strength outweighs cost considerations. For applications requiring clear, lightweight, and economical materials such as display cases, signage, and packaging, polystyrene delivers optimal transparency with budget efficiency.

Polystyrene transparency vs Polycarbonate transparency Infographic

materialdif.com

materialdif.com