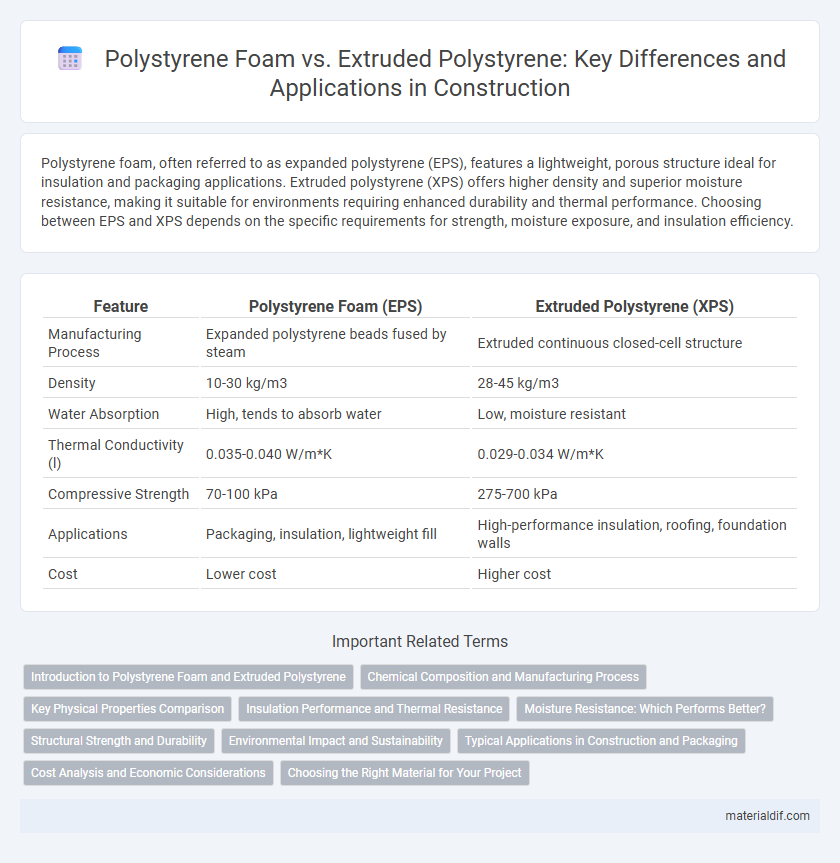

Polystyrene foam, often referred to as expanded polystyrene (EPS), features a lightweight, porous structure ideal for insulation and packaging applications. Extruded polystyrene (XPS) offers higher density and superior moisture resistance, making it suitable for environments requiring enhanced durability and thermal performance. Choosing between EPS and XPS depends on the specific requirements for strength, moisture exposure, and insulation efficiency.

Table of Comparison

| Feature | Polystyrene Foam (EPS) | Extruded Polystyrene (XPS) |

|---|---|---|

| Manufacturing Process | Expanded polystyrene beads fused by steam | Extruded continuous closed-cell structure |

| Density | 10-30 kg/m3 | 28-45 kg/m3 |

| Water Absorption | High, tends to absorb water | Low, moisture resistant |

| Thermal Conductivity (l) | 0.035-0.040 W/m*K | 0.029-0.034 W/m*K |

| Compressive Strength | 70-100 kPa | 275-700 kPa |

| Applications | Packaging, insulation, lightweight fill | High-performance insulation, roofing, foundation walls |

| Cost | Lower cost | Higher cost |

Introduction to Polystyrene Foam and Extruded Polystyrene

Polystyrene foam, commonly known as expanded polystyrene (EPS), consists of lightweight, rigid cellular materials primarily used for insulation and packaging due to its excellent thermal resistance and shock absorption properties. Extruded polystyrene (XPS) differs by its manufacturing process, producing a denser, closed-cell foam with superior moisture resistance and higher compressive strength, making it ideal for structural insulation applications. Both EPS and XPS are valued in construction and packaging industries for their thermal insulation efficiencies, but XPS offers enhanced durability and water resistance compared to traditional EPS foam.

Chemical Composition and Manufacturing Process

Polystyrene foam, typically expanded polystyrene (EPS), is produced by expanding pre-polymerized polystyrene beads containing a blowing agent, whereas extruded polystyrene (XPS) is created by melting and extruding polystyrene pellets with additives under high pressure. Chemically, both consist primarily of polystyrene, but EPS contains trapped air pockets from the bead expansion, resulting in a more porous structure, while XPS features a closed-cell, uniform matrix due to its continuous extrusion process. The manufacturing distinctions lead to differences in density, thermal insulation properties, and moisture resistance between EPS and XPS materials.

Key Physical Properties Comparison

Polystyrene foam, commonly known as expanded polystyrene (EPS), exhibits low density and high thermal insulation with a compressive strength typically around 15-25 psi. Extruded polystyrene (XPS) offers higher density and greater moisture resistance, with compressive strength ranging between 25-40 psi, making it more durable for load-bearing applications. Both materials have similar R-values per inch, approximately 3.6 to 5, but XPS provides superior long-term thermal performance due to its closed-cell structure.

Insulation Performance and Thermal Resistance

Polystyrene foam, specifically expanded polystyrene (EPS), offers good insulation performance with a typical thermal resistance (R-value) of around 3.6 to 4.0 per inch, making it effective for reducing heat transfer in building applications. Extruded polystyrene (XPS) foam provides superior thermal resistance, with R-values generally between 5.0 and 5.6 per inch, due to its denser, closed-cell structure that minimizes moisture absorption and enhances insulation longevity. The higher durability and moisture resistance of XPS make it a preferred choice for environments requiring consistent thermal performance and greater structural strength.

Moisture Resistance: Which Performs Better?

Extruded polystyrene (XPS) outperforms polystyrene foam in moisture resistance due to its closed-cell structure, which significantly reduces water absorption and enhances durability in wet environments. Polystyrene foam, commonly expanded polystyrene (EPS), has an open-cell structure that allows higher water infiltration, leading to compromised insulation properties over time. Therefore, XPS is preferred in applications requiring superior moisture resistance and long-term performance.

Structural Strength and Durability

Polystyrene foam, typically expanded polystyrene (EPS), offers moderate structural strength and is commonly used in insulation and packaging due to its lightweight nature. Extruded polystyrene (XPS) provides superior structural strength and enhanced durability, making it more resistant to moisture, compression, and impact over time. XPS's closed-cell structure ensures better long-term performance in construction applications compared to the more porous EPS.

Environmental Impact and Sustainability

Polystyrene foam, commonly used in packaging and insulation, is lightweight but faces challenges in recycling due to its bulky nature, leading to significant landfill accumulation and environmental pollution. Extruded polystyrene (XPS) offers improved durability and moisture resistance, but its production involves higher greenhouse gas emissions, including the use of hydrofluorocarbon blowing agents recognized for their global warming potential. Sustainable practices emphasize developing recycling technologies and transitioning to eco-friendly blowing agents to reduce the environmental footprint of both materials.

Typical Applications in Construction and Packaging

Polystyrene foam, commonly known as expanded polystyrene (EPS), is widely used in construction for insulation in walls, roofs, and foundations due to its lightweight and thermal resistance. Extruded polystyrene (XPS) offers higher compressive strength and moisture resistance, making it ideal for below-grade insulation, roofing boards, and structural insulated panels. In packaging, EPS protects delicate items like electronics and appliances with cushioning properties, while XPS is preferred for heavy-duty packaging requiring durability and impact resistance.

Cost Analysis and Economic Considerations

Polystyrene foam, commonly known as expanded polystyrene (EPS), tends to have lower upfront costs compared to extruded polystyrene (XPS) due to its simpler manufacturing process and lighter weight. However, XPS offers better insulation performance and moisture resistance, potentially leading to long-term savings on energy bills and maintenance costs. Economic considerations must balance initial investment against durability and efficiency, with XPS often favored in applications demanding superior thermal insulation and structural strength.

Choosing the Right Material for Your Project

Polystyrene foam, commonly used for insulation and packaging, offers lightweight and cost-effective thermal resistance but may lack the durability and moisture resistance of extruded polystyrene (XPS). Extruded polystyrene provides superior compressive strength, water repellency, and long-term performance, making it ideal for construction projects requiring enhanced durability and moisture protection. Selecting between expanded polystyrene (EPS) and XPS depends on project-specific needs such as load-bearing requirements, exposure to moisture, and budget constraints.

Polystyrene foam vs Extruded polystyrene Infographic

materialdif.com

materialdif.com